BGA Repair & Rework Services

Why BEST for BGA Rework Services?

Your BEST Source For High-Quality Industry-Leading BGA Rework and Repair

Ball grid array (BGA) devices that are mass-produced are often in need of reworking for a number of reasons, including:

When the gold fingers get scratched, contaminated with solder or if the plating is worn they can be re-plated by BEST. The contaminated contacts are stripped down to the bare base metal and replaced to meet the thickness specified. BEST's electroplating process is reliable and will restore damaged contacts to "like new" condition with full functional conductivity and durability.

- Devices that have defects or

- Solder joints that are either insufficient or excessive (most often occurring during the assembly process) or

- Changes/alterations/upgrades to engineering parts

Damaged or missing BGA pads are another common issue at BGA sites that require ball grid array repair to be done. These pads are replaced following an IPC recommended procedure which uses specially fabricated adhesive-backed BGA pads that are bonded to the board surface. But before this ball grid array repair procedure can get started, the lifted solder pads need to be repaired. The reason? Repair of damaged solder mask between BGA pads and connecting vias is a critical step to prevent solder from flowing down the vias during the BGA pad replacement process. This step needs to be accomplished prior to placement of the replacement BGA as part of the (ball grid array) BGA rework process.

BGA Rework /Repair: The BEST Solution

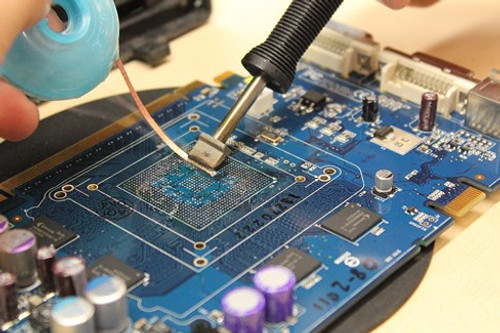

When you have a design that requires changes or modifications at a BGA site, using a standard jumper wire is not normally a viable option. Jumper wires are simply too large to fit under a BGA component. A repair or modification employs the use of flat copper ribbon that is thin enough to fit safely under the BGA component. This BGA repair will allow you to save your design and avoid the costly expense of doing another board build.

BEST provides industry-leading solutions for BGA and other grid array device reworks. Our engineers have developed better processes to make BGA repair and rework more repeatable, consistent and reliable. We have been reworking BGAs since their inception, and continue to stay on the cutting edge with the latest package styles and techniques.If you need expensive or sensitive components salvaged from a PCB then BEST is your source for BGA component salvaging.

When you partner with BEST, we leverage our extensive industry experience and commitment to quality and customer service to bring you several benefits you will not find elsewhere, including:

- The most advanced re-work equipment available on the market today – we always have the best tool for any job.

- IPC-Certified Technicians specially trained for BGA rework and x-ray verification assigned to EVERY job.

- Full transparency with a disc of appropriate x-ray images returned to you after the job is complete.

Your Full Service BGA Rework Partner

At BEST, we are your 'one-stop' solution, offering a wide range of ball grid array rework and repair services that include:

- BGA component removal

- Site Prep

- Replacement

- BGA Salvaging

- X-ray or optical verification

- Circuit Design Changes

- BGA Pad Repair

- Trace Repair

- Mask Repair

- BGA Underfill

- BGA Part Salvaging

- BGA Rework and Technical Support Certification Classes

We can also help you diagnose and troubleshoot your own ball grid array rework process. Our knowledgeable SMT process engineers can review your process documentation, audit your BGA rework or ball grid array repair process or develop a highly successful one for your operation including the development of thermal profiles which are critical to reworking the location without knowing the specifics of how to run your ball grid array rework equipment.

BGA Rework video

BGA Reballing Process Overview Plastic Package, Low Volume

|

BGA Reballing Process Overview Ceramic/Metal Package, Low Volume

|