Indium Corporation

Solder pastes, solder preforms, solder spheres, soldering fluxes, electrically-conductive adhesives. All alloys: tin-lead, lead-free, indium alloys, and more.

Indium Corporation is a premier materials supplier to the global electronics, semiconductor, solar, thin film and thermal management markets. Products include solders, performs, and fluxes; brazes; sputter targets; indium, gallium, and germanium chemicals and sourcing; and Reactive NanoFoil®.

Founded in 1934, Indium has global technical support and factories located in China, Singapore, South Korea, the United Kingdom, and the USA.

Indium Corporation Postings

10 products »

Durafuse™ LT - Low Temperature Solder Paste

Durafuse™ LT is a novel, low-temperature alloy system designed to provide high-reliability in low applications that are looking for a reflow temperature below 210°C. Where traditional low-temperature solders often...

Indium6.4R Water-Soluble Pb-Free Solder Paste

Indium6.4R is a versatile, water-soluble solder paste flux, formulated for air or nitrogen reflow. It excels in both SnPb and Pb-free assembly processes, providing an exceptional reflow process window. This solder paste delivers outstanding stenci...

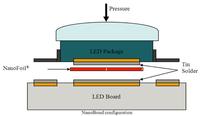

NanoFoil® Multi-Layer Bonding Material

NanoFoil® reactive multi-layer foil is a controllable and affordable bonding material, proven to lower manufacturing costs while providing repeatable and reliable bonds. NanoFoil® is a reactive multi-layer foil that provide...

Indium8.9 Pb-Free Solder Paste

Solves: QFN Voiding | Head-in-Pillow | Graping Indium8.9 is an air or nitrogen reflow, no-clean solder paste specifically formulated to accommodate the higher processing temperatures required by the SnAgCu, SnAg, and other alloy system...

Superior Drop Shock Performance AND Thermal Cycling Reliability Current Industry Dilemma The standard set of Pb-free alloys has a dramatic trade-off between thermal cycling and drop testing. Addit...

New Precision BGA Spheres Optimize Sphere Performance Indium Corporation’s Solder Spheres for PBGA, CBGA, TBGA, µBGA¬ and Flip Chip applications are made by a proprietary manufacturing process that consistently resu...

Solder Wire from the Indium Corporation is made to demanding quality standards. Our flexible manufacturing process allows us to fulfill orders from evaluation/research quantities to full scale production volumes. Indium Solde...

Indium Corporation manufactures high quality solder powders and pastes. Powders are available in hundreds of alloys and a full range of sizes. Solder pastes can be made from these powders using a wide variety of flux vehicles to g...

Preforms come in standard shapes such as squares, rectangles, washers and discs. Typical sizes range from .010" (.254mm) up to 2" (50.8mm). Smaller and larger sizes, as well as custom shapes, are also available. Dimensions can be held...

Indium Corporation is a developer, manufacturer, and global supplier of: specialty solders (including solder paste, preforms, spheres, columns, wire, tubing, ribbon, and foil), fluxes, electrically-conductive adhesives, inorganic compounds (inc...

27 technical articles »

LEAD-FREE FLUX TECHNOLOGY AND INFLUENCE ON CLEANING

Oct 11, 2022 | Ning-Cheng Lee, Ph.D.

Lead-free flux technology for electronic industry is mainly driven by high soldering temperature, high alloy surface tension, miniaturization, air soldering due to low cost consideration, and environmental concern. Accordingly, the flux features desired included high thermal stability, high resistance against burn-off, high oxidation resistance, high oxygen barrier capability, low surface tension, high fluxing capacity, slow wetting, low moisture pickup, high hot viscosity, and halogen-free. For each of the features listed above, corresponding desired chemical structures can be deduced, and the impact of those structures on flux residue cleanability can be speculated. Overall, lead-free flux technology results in a greater difficulty in cleaning. Cleaner with a better matching solvency for the residue as well as a higher cleaning temperature or agitation are needed. Alkaline and polar cleaner are often needed to deal with the larger quantity of fluxing products. Reactive cleaner is also desired to address the side reaction products such as crosslinked residue....

Nov 24, 2020 | Fen Chen and Ning Cheng Lee, Ph.D.

The miniaturization trend is driving industry to adopting low standoff components or components in cavity. The cost reduction pressure is pushing telecommunication industry to combine assembly of components and electromagnetic shield in one single reflow process. As a result, the flux outgassing/drying is getting very difficult for devices due to poor venting channel. This resulted in insufficiently dried/burnt-off flux residue. For a properly formulated flux, the remaining flux activity posed no issue in a dried flux residue for no-clean process. However, when venting channel is blocked, not only solvents remain, but also activators could not be burnt off. The presence of solvents allows mobility of active ingredients and the associated corrosion, thus poses a major threat to the reliability. In this work, a new halogen-free no-clean SnAgCu solder paste, 33-76-1, has been developed. This solder paste exhibited SIR value above the IPC spec 100 MΩ without any dendrite formation, even with a wet flux residue on the comb pattern. The wet flux residue was caused by covering the comb pattern with 10 mm × 10 mm glass slide during reflow and SIR testing in order to mimic the poorly vented low standoff components. The paste 33-76-1 also showed very good SMT assembly performance, including voiding of QFN and HIP resistance. The wetting ability of paste 33-76-1 was very good under nitrogen. For air reflow, 33-76-1 still matched paste C which is widely accepted by industry for air reflow process. The above good performance on both non-corrosivity with wet flux residue and robust SMT process can only be accomplished through a breakthrough in flux technology....

Jul 24, 2019 | Brook Sandy-Smith

Voiding is a key concern for components with thermal planes because interruptions in Z-axis continuity of the solder joint will hinder thermal transfer. When assembling components with solder paste, there is a high propensity for voiding due to the confined nature of the solder paste deposits under the component. Once reflowed, many factors contribute to the amount of voiding in a solder joint such as the reflow profile, designs of the component, board and stencil, and material factors. This study will focus on the solder paste alloy and flux combination as well as profile and board surface finishes....

Process Optimization for Fine Feature Solder Paste Dispensing

Dec 19, 2018 | Maria Durham, Greg Wade, and Brandon Judd; Indium Corporation, John Boggiatto; ITW EAE - Speedline Technologies

With the rapid trend towards miniaturization in surface mount and MEMs lid-attach technology, it is becoming increasingly challenging to dispense solder paste in ultra-fine dot applications such as those involving chip capacitors or BGA packages, as well as dispensing ultra-fine lines in MEMs lid-attach applications. In order to achieve ultra-fine dots and fine line widths while dispensing solder paste, both the solder material and dispensing equipment need to be optimized. Optimizing the equipment can be very challenging, as there are many input variables that can affect the dispense quality of the solder paste. In this paper we will evaluate the many equipment variables involved in the solder paste dispensing process, and the impact these variables have on the dispense quality of the solder paste....

Nov 20, 2018 | Brook Sandy-Smith, Indium Corporation and Terry Munson, Foresite Inc.

There are several industry-accepted methods for determining the reliability of flux residues after assembly. The recommended methods of test sample preparation do not always closely mimic the thermal cycle experienced by an assembly. Therefore, extraction from actual assemblies has become a popular method of process control to assess consistency of post-reflow cleanliness. Every method of post-reflow flux residue characterization will depend on the reflow process followed to prepare the coupon.

This investigation will focus on the effect of thermal conditions on the remainder of active ingredients in flux residues after assembly with no-clean solder pastes....

Does Thermal Cycling Impact the Electrical Reliability of a No-Clean Solder Paste Flux Residue

Aug 29, 2018 | Eric Bastow

No-clean solder pastes are widely used in a number of applications that are exposed to wide variations in temperature during the life of the assembled electronics device. Some have observed that cracks can and do form in flux residue and have postulated that this is the result of or exacerbated by temperature cycling. Furthermore, the potential exists for the flux residue to soften or liquefy at elevated temperatures, and even flow if orientated parallel to gravity. In situations such as in automotive electronics, where significant temperature cycling is a reality and high reliability is a must, concern sometimes exists that the cracking and possible softening or liquefying of the residue may have a deleterious effect on the electrical reliability of the flux residue. This paper will attempt to address this concern....

A Novel Solution for No-Clean Flux not Fully Dried under Component Terminations

Aug 17, 2017 | Dr. Ning-Cheng Lee & Fen Chen

At SMT assembly, flux outgassing/drying is difficult for devices with poor venting channel, and resulted in insufficiently dried/burnt-off flux residue for no-clean process.

Examples including:

- Large low stand-off components such as QFN, LGA

- Components covered under electromagnetic shield which has either no or few venting holes

- Components assembled within cavity of board

- Any other devices with small open space around solder joints

A Novel Epoxy Flux On Solder Paste For Assembling Thermally Warped POP

Aug 17, 2017 | Ming Hu, Lee Kresge, and Ning-Cheng Lee

A novel epoxy flux EF-A was developed with good compatibility with no-clean solder pastes, and imparts high reliability for BGA assembly at a low cost. This compatibility with solder pastes is achieved by a well-engineered miscibility between epoxy and no-clean solder paste flux systems, and is further assured with the introduction of a venting channel. The compatibility enables a single bonding step for BGAs or CSPs, which exhibit high thermal warpage, to form a high-reliability assembly. Requirements in drop test, thermal cycling test (TCT), and SIR are all met by this epoxy flux, EF-A. The high viscosity stability at ambient temperature is another critical element in building a robust and userfriendly epoxy flux system. EF-A can be deposited with dipping, dispensing, and jetting. Its 75°C Tg facilitates good reworkability and minimizes the adverse impact of unfilled underfill material on TCT of BGA assemblies....

Establishing a Precision Stencil Printing Process for Miniaturized Electronics Assembly

Jun 13, 2017 | Chris Anglin

The advent of miniaturized electronics for mobile phones and other portable devices has required the assembly of smaller and smaller components. Currently 01005 passives and 0.3 mm CSPs are some of the components that must be assembled to enable these portable electronic devices. It is widely accepted that about 65% of all end of the line defects occur in the stencil printing process. Given all of the above, it is critical that a precision stencil printing process be developed to support miniaturized electronic assembly.

This paper is a summary of a significant amount of experimental data and process optimization techniques that were employed to establish a precision SMT printing process....

Can Age and Storage Conditions Affect the SIR Performance of a No-Clean Solder Paste Flux Residue?

Feb 09, 2017 | Eric Bastow

The SMT assembly world, especially within the commercial electronics realm, is dominated by no-clean solder paste technology. A solder paste flux residue that does not require removal is very attractive in a competitive world where every penny of assembly cost counts. One important aspect of the reliability of assembled devices is the nature of the no-clean solder paste flux residue. Most people in this field understand the importance of having a process that renders the solder paste flux residue as benign and inert as possible, thereby ensuring electrical reliability.

But, of all the factors that play into the electrical reliability of the solder paste flux residue, is there any impact made by the age of the solder paste and how it was stored? This paper uses J-STD-004B SIR (Surface Insulation Resistance) testing to examine this question....

418 news releases »

Indium Corporation Advisor to Present, Host Tutorial at TestConX 2024

![]() Feb 26, 2024 | Indium Corporation advisor, and founder/principal of DS&A LLC, Dave Saums will present on innovative thermal materials for semiconductor testing at TestConX 2024, held in Mesa, AZ, March 3-6. Saums will open the conference with a tutorial on March 3 and deliver a technical presentation on the topic on March 5.

Feb 26, 2024 | Indium Corporation advisor, and founder/principal of DS&A LLC, Dave Saums will present on innovative thermal materials for semiconductor testing at TestConX 2024, held in Mesa, AZ, March 3-6. Saums will open the conference with a tutorial on March 3 and deliver a technical presentation on the topic on March 5.

Indium Corporation Expert to Present Technical Paper at IMAPS France

![]() Feb 19, 2024 | Indium Corporation Technical Manager for Europe, Africa, and the Middle East Karthik Vijay will present a technical paper on January 31 at IMAPS France – 17th European Advanced Technology Workshop on Micropackaging and Thermal Management in La Rochelle, France.

Feb 19, 2024 | Indium Corporation Technical Manager for Europe, Africa, and the Middle East Karthik Vijay will present a technical paper on January 31 at IMAPS France – 17th European Advanced Technology Workshop on Micropackaging and Thermal Management in La Rochelle, France.

Indium Corporation Prepared to Deliver Three Presentations at APEC 2024

![]() Feb 19, 2024 | As one of the leading materials providers to the power electronics assembly industry, three Indium Corporation team members will share their insights and knowledge on a variety of industry-related topics throughout APEC 2024, February 25-29, in Long Beach, CA.

Feb 19, 2024 | As one of the leading materials providers to the power electronics assembly industry, three Indium Corporation team members will share their insights and knowledge on a variety of industry-related topics throughout APEC 2024, February 25-29, in Long Beach, CA.

Indium Corporation to Kick Off Season Three of EV InSIDER Live Webcast Series with Charging Session

![]() Feb 19, 2024 | Indium Corporation's EV InSIDER Live webcast series is set to launch its third season on February 22 with a live LinkedIn session titled Fixing America's Broken Fast Chargers, featuring special guest Kameale Terry. Terry is co-founder and CEO of ChargerHelp!, a company that enables on-demand repair of EV charging stations.

Feb 19, 2024 | Indium Corporation's EV InSIDER Live webcast series is set to launch its third season on February 22 with a live LinkedIn session titled Fixing America's Broken Fast Chargers, featuring special guest Kameale Terry. Terry is co-founder and CEO of ChargerHelp!, a company that enables on-demand repair of EV charging stations.

Indium Corporation Experts to Present at SMTA Pan Pac

![]() Jan 29, 2024 | Two Indium Corporation experts are set to deliver technical presentations on low-temperature soldering at the upcoming Pan Pacific Strategic Electronics Symposium (Pan Pac), hosted by SMTA, January 29–February 1 in Hawaii.

Jan 29, 2024 | Two Indium Corporation experts are set to deliver technical presentations on low-temperature soldering at the upcoming Pan Pacific Strategic Electronics Symposium (Pan Pac), hosted by SMTA, January 29–February 1 in Hawaii.

Indium Corporation to Feature Precision Au-Based Die-Attach Preforms at SPIE Photonics West

![]() Jan 29, 2024 | Indium Corporation® will feature its high-reliability, Au-based precision die-attach (PDA) preforms for critical laser and RF applications at SPIE Photonics West, Jan. 27-Feb. 1, in San Francisco. SPIE West is the world's premier event for lasers, biomedical optics and biophotonic technologies, quantum, and optoelectronics.

Jan 29, 2024 | Indium Corporation® will feature its high-reliability, Au-based precision die-attach (PDA) preforms for critical laser and RF applications at SPIE Photonics West, Jan. 27-Feb. 1, in San Francisco. SPIE West is the world's premier event for lasers, biomedical optics and biophotonic technologies, quantum, and optoelectronics.

Indium Corporation to Feature High-Reliability Materials for Power Electronics at NEPCON Japan

![]() Jan 29, 2024 | Indium Corporation® is proud to showcase its proven advanced assembly materials for power electronics, including the rapidly evolving electric vehicle (EV) manufacturing and e-Mobility market, at NEPCON Japan, January 24-26, in Tokyo, Japan. Indium Corporation's products for power electronics have been demonstrated to reduce energy consumption and solve warpage issues for its customers while ensuring high reliability and improving overall efficiency.

Jan 29, 2024 | Indium Corporation® is proud to showcase its proven advanced assembly materials for power electronics, including the rapidly evolving electric vehicle (EV) manufacturing and e-Mobility market, at NEPCON Japan, January 24-26, in Tokyo, Japan. Indium Corporation's products for power electronics have been demonstrated to reduce energy consumption and solve warpage issues for its customers while ensuring high reliability and improving overall efficiency.

Indium Corporation Announces Updates to China Leadership Team

![]() Jan 29, 2024 | Indium Corporation is pleased to announce the promotions of Taylor Wang and Walter Wang, key members of its China-based leadership team. Taylor Wang has assumed the role of Associate Director, China Sales, while Walter Wang has taken on the position of Associate Director, Operations.

Jan 29, 2024 | Indium Corporation is pleased to announce the promotions of Taylor Wang and Walter Wang, key members of its China-based leadership team. Taylor Wang has assumed the role of Associate Director, China Sales, while Walter Wang has taken on the position of Associate Director, Operations.

Indium Corporation Expert to Present at iNEMI Seminar Hosted by Zestron Europe

![]() Jan 29, 2024 | Indium Corporation Regional Technical Manager and Technologist – Advanced Applications Andreas Karch will present at iNEMI's upcoming seminar, Humidity Robustness and Isolation Coordination for e-Mobility. The seminar, hosted by ZESTRON Europe, will be held on February 1 in Ingolstadt, Germany.

Jan 29, 2024 | Indium Corporation Regional Technical Manager and Technologist – Advanced Applications Andreas Karch will present at iNEMI's upcoming seminar, Humidity Robustness and Isolation Coordination for e-Mobility. The seminar, hosted by ZESTRON Europe, will be held on February 1 in Ingolstadt, Germany.

Indium Corporation Expert to Present at Power Device & Module Expo at NEPCON Japan

![]() Jan 08, 2024 | Indium Corporation Senior Area Technical Manager Jason Chou is set to deliver a presentation at the Power Device & Module Expo, held in conjunction with NEPCON Japan, on January 24 in Tokyo. The presentation will explore trends in EV power electronics and the interconnect materials that enable them.

Jan 08, 2024 | Indium Corporation Senior Area Technical Manager Jason Chou is set to deliver a presentation at the Power Device & Module Expo, held in conjunction with NEPCON Japan, on January 24 in Tokyo. The presentation will explore trends in EV power electronics and the interconnect materials that enable them.