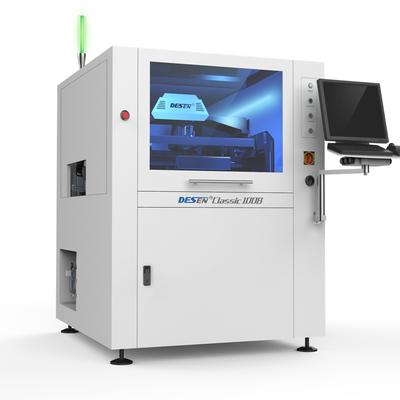

Automatic Screen Printer

Company Information:

Name: |

Automatic Screen Printer |

Category: |

|

Offered by: |

|

Automatic Screen Printer Description:

| DESEN Classic 1008 SPECIFICATIONS | |

| Process Parameters | Specification |

Machine Alignment Capability |

≥2 Cpk@±25μm@,6σ |

Process Alignment Capability |

≥2 Cpk@±10μm@,6σ |

| Cycle Time | 7s |

Maximum Print Area |

400mm x340mm, |

| Screen Frame Size | 470mm x 370mm~737mm x 737mm |

| Screen Frame Thickness | 25mm - 40mm |

| Print Pressure | 0kg - 10kg |

| Print Speed | 1mm/sec - 200mm/sec |

| Print Gap | 0mm - 20mm |

| Substrate Separation | 脱模速度:0.1 - 20mm/s Speed:0.1mm/sec - 20mm/sec 脱模距离:0mm - 3mm Distance:0mm - 3mm |

| Separation option | 先起刮刀再脱模,先脱模再起刮刀 Separation after squeegee up; Squeegee up after separation |

| Apply paste option | solder paste,printing ink, silver paste |

| Transfer System | Specification |

| Type | U gear belt, front rail fixed |

| ESD Compatibility | Black transport belts and guides with surface resistivity of greater than 110 Ω |

| Width Adjustment | Programmable motorized rear rail |

| Transport Direction | L→R,L→L,R→L,R→R |

| Substrate Handling Size (minimum) | 50mm (X) x 50mm (Y) |

| Substrate Handling Size (maximum) | 400mm (X) x340mm (Y), |

| Substrate Thickness | 0.4mm - 5 mm |

| Substrate Weight | ≤3kg |

| Substrate Warpage | ≤1% |

| Substrate Fixture | Flexible side clamp |

| Substrate Underside Clearance | ≤16mm |

| Vision | Specification |

| Multi function image process system | Mark 2mm,FOV:10*8mm Fiducial Mark software measurement,twice position,device identification function,Digital camera: 1 million 300 thousand pixels,the camera scene depth 2mm FOV:10*8mm |

| Fiducial Recognition | Automatic fiducial teach and find incorporating 0.1mm fiducial capture |

| Fiducials | Two or Four Fiducial Marks Alignment System |

| Fiducial Types | square, round, triangle, cross,user- defined types |

| Fiducial Size | 0.1mm ~ 3mm |

| Fiducial Locations | Anywhere on substrate |

| Fiducial Error Recovery | Auto lighting adjustment Auto fiducial search |

| Camera Lighting | Manual adjustment |

| 2D inspect system | 2D detect solder printing quality |

| Software & Communications | Specification |

| Software intelligent backup module | Database automatic backup, software upgrade is not lost |

| Maintenance early warning function | Machine wire rod, slide block, motor and other automatic maintenance message |

| printing parameter intelligent module | Customer select the type of production,like FPC,LED,Phone PCB... the printer can give the parameter automatically. |

Recovery system of solder paste |

The fixed frequency to recovery the solder paste into the printing area. |

| Standard Configuration | Specification |

| Printer Construction | One piece optimized welded frame |

| Machine Control | Three control motion control card |

| Operation System | Windows XP,Win7(option) |

| Operator Interface | 17 "DELL display screen, keyboard and mouse and DESEN V2 software, display on the right hand side. |

| Squeegee | Direct screw/single-point suspension squeegee |

Constant intelligent control system of squeegee pressure |

Pressure adjusted by software control |

| Automatic positioning module of stencil | Put the stencil into the support frame,the squeegee automatically realizes the positioning of the stencil |

support positioning system |

support, support pin, supportplatform |

Intelligent cleaning system |

The diffrent size of wipe paper can be used ,less paper consumption,solvent agent control module |

| Stencil Alignment | Program control, Y direction orientated |

| Machine Interface | SEMI Input/Output 4 core international standard interface |

| Connectivity | RJ-45LAN(networking) and USB2 interface available |

| Three color intelligent LED warning light | Programmable with audible alarm |

| High performance and high precision platform | The platform processing method adopts the annealing process and the knife quick milling method, and the residual of the metal stress in the platform is reduced.Easy deformation, precision assurance. |

Fast platform adjustment system |

Knob type manual rapid adjustment platform height |

Intelligent compensation platform |

X, Y, θ multi axis independent adjustment |

| Intelligent transmission system | The automatic limit device + automatic positioning substrate + left into the left, the left into the right, right into the right, right into the left out |

| Documentation | Hard copy manuals comprising:Opeartor,Installation,and Electrical Drawings. On board technical manuals and tutorials supporting operator functions. |

| Approximate Dimensions | 1140(L)X1360(W)X1505(H)mm |

| Approximate Weight | 1300kg boxed (dependent upon configured options selected with machine) 1100kg unboxed (dependent upon configured options selected with machine) |

| Electric parameter | Specification |

| Voltage | 220Volts +/- 10%.Single phase 50/60Hz |

| Power | 3kw |

| Over Current Protection | The external circuit breaker protection, ≤25 Amps |

| Air Supply | 0.45- 0.6kg/cm² |

| Temperature | 25±3℃ |

| Humidity | 30% - 70% relative humidity (non condensing) |

| Certification | Specification |

| CE | 98/37/EC,89/336/EEC,73/23/EEC |

| Acoustic Noise Level | Less than 87dB |

Automatic Screen Printer was added in Oct 2017

Automatic Screen Printer has been viewed 564 times

11 More Products from Shenzhen Gosmt Technology Co., Ltd :