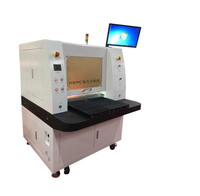

0.8-3.2 mm V-CUT aluminum plate,V-CUT Cutting Machine

Company Information:

Name: |

0.8-3.2 mm V-CUT aluminum plate,V-CUT Cutting Machine |

Category: |

|

Offered by: |

|

0.8-3.2 mm V-CUT aluminum plate,V-CUT Cutting Machine Description:

V-CUT Cutting Machine Operating instructions:

一. Specification :

Product Name: PCB board v groove machine (5 pairs of plastic shaft)

Cutting width: 75mm wide vertical 380MM

Thickness: 0.8-3.2 mm

Cardboard each time V≥10 pit (above and below 10 knives)

Aluminum plate each time V≥ 5 pit (4 knife up and down)

PCB Board each time V≥ 8 pit (upper and lower knives 8)

Speed: 8 m / min

Spindle motor: 3KW inverter 3.7KW plastic shaft motor 120W close crate motor 60W

Mechanical Dimensions: 1200 mm x 980 mm x 1400 mm (W x D x H)

Weight: 145KG

Accessories: gasket set, V-CUT knife 4. Shield bearing 10, each the size of a wrench, a hex key set,

installed a turret.

二.Feature :

1, V-CUT aluminum shaft conveyor transport speed is adjusted to between 20 and 30, the transfer speed

of the thicker plate thinner slower speed can be adjusted faster board, under normal circumstances, the thickness was adjusted to 1.6 by 25 speed.

2, V-CUT aluminum plate conveyor speed adjustment knife arbor fastest speed, can slow the speed

V-CUT ordinary board.

3, V-CUT too ordinary board after V-CUT knife can not be used for V-CUT aluminum plate, V-CUT

aluminum plate with rough edges after the V-CUT knife can also be used for V-CUT ordinary board.

4, V-CUT aluminum plate must be cooled with alcohol, can not participate in water or water cooling.

三.Works Steps

1. V-CUT machine will be around and above the security guards to open the shell cover.

2. Then adjust the depth screw loosening and disassemble.

3. Taoban disassembly of the spindle drive into the middle of the wheel spindle and the spindle bearing

and relax around the upper and lower knife adjusting screw symmetry .

4. Hands hold the spindle vertically upwards heart heart out at the same time, the main axis, the knife

used (3,4) method, will be removed under the spindle.

5. Gasket fixed to the right side of the main axis of the screws removed.

6. 80-100MM first set of gauge pads into the axis, upper and lower knife shaft to the average of the

gasket.

7. Loaded blade in accordance with the requirements of MI size and installed the tool, in the loaded knife

blade when you should pay attention to the direction; the knife blade sharp outward-axis, the knife

blade tip inward axis.

8. Gasket fixed to the spindle to tighten the nut so that the blade can not be loose, and placed on the

bearing sets.

9. By (1,2,3,4) loaded action of the anti-V-CUT machine, good upper and lower knife, and a fixed screw.

四、V-CUT Board

1. By cutting threads tuned adjustment method of the V-CUT board. And screw fixed.

五、Cut Blades and shield bearing mounting method:

1. If the only knife, then knife the two bearing plates care must be to ensure that the average pressure of

the entire board.

2 . Such as twice or more, if the secant from the edge of more than 10mm, while the outer knife bearing

plate to be care. In contrast to the knife inside of the plate bearing care.

3. If the cutter is too wide the distance between the knife and the knife has to care between the bearing

plate.

六.Precautions :

1. Test depth (generally maintain a minimum depth of 0.3-0.4 mm thickness and the depth of the same

on both sides), trial size (size to maintain the accuracy of ± 0.05 mm) and adjust the direction of line

drawings or forming a model for the direction.

2. Check for exposed copper, wound line, V-cut, straight-line is offset, rough.

3. Board's attention to take place the way a good tune after the board should be put in the same

direction.

4. Need to work with masks and gloves in order to avoid dust inhalation mouth.

5. Blade thickness: 2.4mm; bearing thickness: 11.9mm.

6. Production of both sides of the board must be as straight, parallel to the length of more than 80mm

above.

7. Bearing shield such as dust, debris stuck, which may result in non-linear or thread-cutting distortions.

8. Workpiece conveyor track must be kept clean and should be polished often.

9. Moderate elastic wheel drive, oil and scratches do not dip. 10. Films for cutting super hard tungsten steel easy to break, not a collision or fall.

11. Clearance gauge pads placed on the cabinet in accordance with the specifications, do not brush or

excessive percussion gongs, the thickness tolerance of ± 0.015mm.

12. 7 gear oil once the sky, and other mechanical parts required to be kept clean and dry.

七.Maintenance:

1. End of production for each plate using a sharp suction machine to machine panels

Siphoning gray.

2. End time of each production to be down to the tool spindle at the heart rags soiled with oil rubbed on

the point on the axis, to prevent rust

3. Removed per blade and V-CUT shield with anti-rust bearings no maintenance

4. To drive every day to clear out the rubbish

5. Weekly by the maintenance department to assist the V-CUT refueling on a rotational slide area.

0.8-3.2 mm V-CUT aluminum plate,V-CUT Cutting Machine was added in Sep 2020

0.8-3.2 mm V-CUT aluminum plate,V-CUT Cutting Machine has been viewed 213 times

20 More Products from YUSH Electronic Technology Co.,Ltd :