Flexible PCB assembly

Company Information:

Name: |

Flexible PCB assembly |

Category: |

|

Offered by: |

|

Flexible PCB assembly Description:

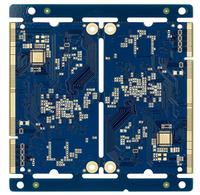

Flexible PCB assembly

Flexible PCB assembly or FPC assembly is a process that is mounting electronic components on flexible plastic substrates such as polyimide, PEEK, or a transparent conductive polyester film.

With the development of electronic products to be short, thin, and light, the integration and miniaturization of electronic components become the trends. And the flexible PCBs came into being and made the circuit boards with unique shapes and sizes. Good flexibility, space-saving, excellent performance are the main advantages of flexible PCBs.

Due to the characteristics, the flexible boards cannot perform surface mounting technology(SMT) like rigid boards. The process of flexible assembly is quite technical. There are two assemble ways of FPC. One is reel to reel(RTR); this way needs a highly specialized production line equipment and high input cost.So, RTR is suitable for substantial batch FPC production. Another assemble way is fixture attachment method, and there are some process points need to be noted as below:

- Pre-baked

- FPC attachment and fixing

- The solder paste printing of FPC

- FPC assembly

The flexible board material is easy to get damp. When the wet board after high-temperature welding, there will be a foaming layer and resulting in scrap. Therefore, PCB manufacturers usually require the flexible board supplier to use vacuum packaging for the incoming materials. But vacuum packaging is not foolproof, and it is best to pre-baked the flexible boards before assembling. After baking, the FPC must be cooled to room temperature before it can be put into production. Otherwise, the hot FPC will cause the solder paste to collapse.

Flexible PCBs are in rapid development and play an important role in lead-free operations.In the next few years, smaller, more complex, and more expensive flexible circuits will require newer methods of assembly. PCB manufacturers or PCB prototype manufacturers should utilize the technological advantages to keep pace with computers, telecommunications, consumer demands, and the development of the markets.

Flexible PCB assembly was added in Sep 2021

Flexible PCB assembly has been viewed 352 times

8 More Products from NextPCB-Reliable Multilayer Boards Manufacturer :