by Sharon Mikesell  , Sonora Manufacturing, Inc.

, Sonora Manufacturing, Inc.

Budget cuts. Those two words cause stress on so many levels. It is more important than ever to be able to perform quality work with less expenditure. Do more with fewer people. Maintain quality performance while buying less equipment.

Luckily, the proper video inspection equipment can help with these issues. By using affordable video inspection equipment, defects can be found and rework can be performed while viewing the micro-image on a monitor screen. With a PC interface, the image can be captured and emailed to engineers, customers, designers or other manufacturing facilities so issues can be quickly resolved.

Video inspection systems can be tailored for use on assembly lines using process control cameras interfaced with a VCR. Other requirements may call for a hand-held camera with self-illumination to view a unique angle. Still other applications are suited for boroscopes. And BGAs may require outer perimeter placement viewing.

Have wire bonds posed a problem? They shouldn't using a high-magnification video inspection system. Stage mounted cameras can bring those tiny wirebonds to your attention quickly and easily. Crowded boards can be easily navigated using foot-pedal activated laser positioning indicators to pinpoint your subject and an X/Y glide stage can be incorporated to minimize subject handling.

However, this is just the beginning of the uses for your video inspection station. Your high-magnification video camera can be easily interfaced with a PC. Simple capture programs will allow annotation of the image with text, arrows or other notations. Measurement software packages are available to perform on-screen measurements, interface with spreadsheets and show split-screen or blink comparisons to known good images.

If you are dealing with multi-lingual facilities, video images can break down communication barriers. In situations where your message could get lost in a translation, show them--don't tell them. Whether you are dealing with your Maquiladora EMS, a vendor in Taiwan or a plant in Japan, an emailed photo of a cracked capacitor tells the story much more clearly than words.

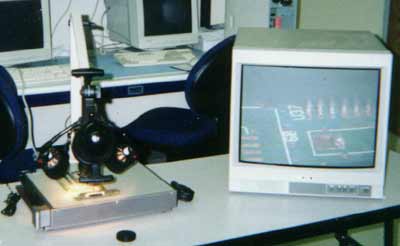

You can also use video inspection systems for training. Instructors can show a class while the image is being shown on a monitor. Many schools and universities are finding the value of investment in video inspection stations for this purpose. Processes can also be recorded and edited for training tapes.

Still other uses for video inspection equipment come into play even before any assembly is taking place! Your incoming inspector may feel a part has arrived that is out of spec. Take a photo of the part and email it directly to the vendor! You can annotate the photo by drawing arrows or circling the questionable area. You can place a known good part next to the received part and show them the differences. This certainly cuts down on phone time between your vendor and your purchasing department and can quickly resolve the situation.

Your video inspection station can also streamline your documentation procedures. When your ISO requirements call for instruction documentation, insert annotated photos for standardization and clarity.

The more ways you can multi-task your video inspection equipment, the better you can justify your ROI. In these days of tight budgets, let your video inspection technology work for you.

Photo Examples

Cracked capacitor on screen of Observatory(tm) inspection station

Observatory(tm) inspection station in use at Sierra College, Rocklin, CA