by Anton Mandos  and Paul Gerits

and Paul Gerits  , Assembl���on b.v.

, Assembl���on b.v.

Odd or SMD? At one time it was clear. An SMD component was placed on the surface of a PCB and all others were defined as 'odds' or 'specials'. For these components electronics manufacturers had to develop individual solutions.

If we look to today's electronics manufacturing market (fig. 1) and its products, such as mobile phones, automotive electronics and consumer electronics, its easy to see that the products are getting ever smaller while the need for greater functionality grows rapidly.

Figure 1

The effect of these drivers is that product manufacturers have to deal with components of ever-greater complexity and an increasingly diverse component mix. As the market demands these new complex products with their functionality and benefits, manufacturers must find ways of building them efficiently.

Finding methods of producing these products in high-volumes will increasingly become a problem for equipment suppliers. No longer do manufacturers look for machine's that solve just one manufacturing problem. Instead, manufacturers expect a "black box" solution from a supplier that's capable of assembling a range of products according to a precise specification and at a reasonable cost. It is also important to that the products and assembly techniques are as future-proof as possible - although nobody can foresee even what the near future in component development will bring.

Black Boxes

"Black box" is the way that electronics manufactures describe the machines that they buy from equipment suppliers. It is a term that comprises a depth of manufacturing knowledge that the manufacturer doesn't want, or need, to be troubled by.

The solution to a manufacturer's business problems does not, as it was in the past, lie with finding answers to individual problems encountered at each manufacturing stage. These days, and increasingly so in the future, the route to success lies with the issues that are related to the product, but other than how the circuits are assembled.

The product is how the manufacturers make their money. But they need increasingly to focus on their strengths, such as concept and brand development, and not waste precious time and money in finding solutions to every manufacturing problem. A black box solution enables them to stay focused on their own strengths.

Such a strategy, though, has a harsh impact on the SMD equipment manufacturers. They continue to need to understand today's markets and applications. But now they need to understand the future in order to develop the tools that will make tomorrow's products a reality.

Although some functions, such as screen-printing, under and over-fill dispensers and wire bounders remain separate processes in some stages of electronic device manufacturing, most equipment is no longer dedicated to a single task. Instead, it has become multi-functional.

Understanding the problems

Lets have a closer look at what SMD equipment manufacturers face in practice now, and what will confront them in the future. Manufacturers already understand the sort of components that will comprise their products. They might be selected from a wide range of "normal" SMD components, including capacitors, resistors, diodes and ICs in a variety of packages. Other commonly used - odd - components include connectors, electrolyte capacitors, sockets and push buttons.

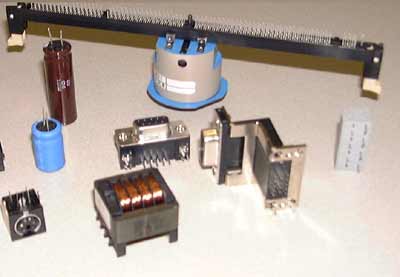

Figure 2

If we look at the assembly process in greater depth it's clear that there are many other requirements that need to be satisfied. Manufacturers opting for black box solutions don't need to worry about these problems. But those who do the assembly work need to consider machine accuracy - a subject that's big enough for another article, machine repeatability, defect levels in terms of defects per million (DPM), production speeds, the availability of different toolbits and various vision systems for handling the components.

What shouldn't be forgotten is the cost per placement (CPP) - also a subject for a separate article. CPP is critical to how quickly the machine's owner gets a return on the investment.

Diverse and unknown

The need to place a diverse range of components at the lowest possible cost has an impact on machine design. To get a better view on this lets' consider some component examples. First, some examples of odds, unidentified SMD.

Odd components include connectors, switches, relays, coils, shields, and modules, as well as insert components.

Second, the drivers of behind equipment development can be shown as the following diagram. As you can see, the driver for the total must be the technology, because technology in future consumer products is the main driving factor. If the consumer demands a new product with new features the electronic manufacturer has to react to this, hence the need for the equipment manufacturer to stay one step ahead.

Figure 3

Still, many different component issues must be taken in consideration when manufacturing equipment of this sort. Machine designers need to understand how to handle the component; how to pick it up; how to align it; how much force can be applied; and many other process related items.

When the equipment is designed according to the above diagram, most issues are understood in regard to standard products. Issues include design of component grippers, force control on placement heads, wide range of camera systems and component feeding systems. It's also desirable is to have a fully self-calibrating system.

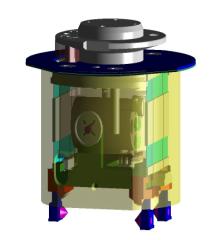

Example of component gripper

Machine components need to be designed to accommodate more than a single component. And, as said, they need to be future proof as far as possible. Examples of how these needs are achieved include flexible and re-configurable component grippers that can be adapted easily for future components.

In case of feeding systems for newly designed components the equipment must be able to handle them all without needing to use complicated adapters, while remaining easy for the operators to use.

Example of a Robodyne stacked tube feeder

Furthermore, high machine accuracy, repeatability, stiffness and flexibility are a must. This is always a standard if the diagram of product development philosophy is used. With regard to accuracy, the machine needs to be far more precise in its operation that is required at present.

For the stiffness, designers aim for a stiffness that doesn't have an impact on accuracy, such as a honeycomb structure. And flexibility means that the machine can be adapted to any circumstances without loss of performance. For example, you want to change the system from odd placer to flip chip placer (or it has to be able to do both), this must be possible with limited time loss and in any case without having to re-calibrate the complete system. Therefore, there is a requirement for self-calibrating systems. In this way human factors can't influence the quality of the product produced by this kind of equipment.

Building Black Boxes for the future

We can conclude that if the right product philosophy is followed, it's possible to place "new" kinds of SMD components automatically. Equipment manufacturers, then, don't need to panic in response to sudden changes in the market, as they are already prepared. They don't need to worry about their "black box" because it already has the capabilities to fulfil their requirements.

Some equipment manufacturers already implemented this in their strategy. Assembl���on has, for many years, worked with the strategy of developing equipment not just for today's market, but also for the market of the future. This requires a deep understanding of what electronic manufacturers' needs and how both the consumer and component markets will develop.

From its association with the Royal Philips group - one of the world's leading consumer electronics and components companies with 100 years of expertise in the development of components, semiconductor design and electronics manufacturing - Assembl���on designers have access to knowledge that helps them to build the machines that industry needs.

SMD or odd? It's a question but not a problem. Black Boxes can enable manufacturers to concentrate on key strengths leaving others, such as Assembl���on, to concentrate on how the components of today and the future should be placed most rapidly and at the lowest cost.

|

| Example of equipment designed as described in the article. The Assembl���on Topaz-Xi and ACM Micro combination. The perfect full solution provider either as standalone or in combination with various other equipment including other manufacturing brands. |