SEHO Systems GmbH, a worldwide leading manufacturer of automated soldering systems and customer-specific solutions, introduces a new software function for its best-selling selective soldering system - the PowerSelective. The new function ensures even higher process reliability by compensating product or production-related warpage of the assemblies to be processed.

Assemblies to be handled in a selective soldering process often do not show the necessary planarity. This warpage may be due to many reasons such as unsymmetrical loaded components, scoring or tensions resulting from previous thermal and mechanical processes.

Any deformation, however, directly affects the z-coordinates in the subsequent selective soldering process, thus negatively impacting the soldering results. To achieve a reliable and reproducible process, particularly critical assemblies require careful consideration on a per board basis to compensate for any distortion. The new software feature available for the PowerSelective guarantees an automated and reliable procedure.

During program generation for the mini-wave soldering process, the operator specifies all board areas that are mechanically supported and gives a correct z-level. Typically, these areas are at the gripper supports or the edges of a carrier in which the boards are processed. A reference point is defined within this area. Additionally, the operator specifies an arbitrary number of points on the soldering side of the assembly.

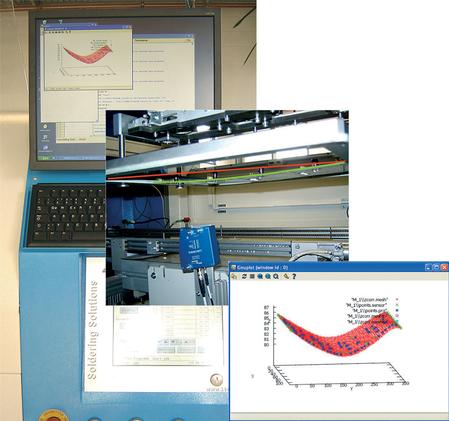

During operation, a high-precision laser measuring system determines the actual distance of the PCB from the previously defined points prior to soldering. These values and the z height of the reference point are the basis for a precise calculation for modelling and illustrating an altitude profile for the assembly in process. All points of the soldering program are set off against the modelled value, ensuring that all points are soldered at the optimum height regardless of actual board warpage.

The PCB warpage compensation, together with the automatic PCB alignment based on fiducial recognition, guarantees optimum and highly reproducible xyz positioning, thus going one step further in zero-fault production.

Since its foundation in 1973, SEHO has become the worldwide contact partner whenever soldering is involved. Company solutions are based on performance, flexibility, efficiency and technical progress. SEHO’s business activities and production organization are oriented according to the principles of sustained future-compatible development and production of machines. As a result, all applicable environmental standards are complied with meticulously. With its systems, the company provides customers with a sustained and resource economizing production facility. It continuously develops its technology in order to provide customers with a competitive advantage.