When speaking of air conditioners, everyone is familiar with them. Especially in the hot summer, we would not know how to live without it. But when it comes to refrigeration compressors, many consumers are not particularly clear. In fact, the refrigeration compressor is an important part of air conditioners and refrigerators, and its performance and quality directly determine the cooling effect of them. The following is an introduction to the types of refrigeration compressors.

1. Two Main Types of Refrigeration Compressors

The refrigeration compressor is the core and heart of the refrigeration system. The capacity and characteristics of the compressor determines the capacity and characteristics of the refrigeration system. In a sense, the design and matching of the refrigeration system reflects the capabilities of the compressor.

Therefore, the refrigeration industry of all countries in the world has invested a lot of energy in the research of refrigeration compressors, and new research directions and research results continue to appear. The technology and performance level of compressors is changing with each passing day.

The refrigeration compressor is a kind of machinery that increases the gas pressure, and it plays an important role in the refrigeration system. Refrigeration compressors can be divided into volume type and speed type according to their thermodynamic principles.

1.1 Volume Type/Positive Displacement Compressor

Figure 2: Rotor of air screw compressor.

Positive displacement refrigeration compressors forcibly compress a certain volume of gas to reduce the volume of the gas and increase its pressure. Positive displacement compressors can be divided into two structural forms: piston type and rotary type.

Piston-type refrigeration compressors use a crank and connecting rod mechanism to convert the rotary motion of the prime mover into reciprocating motion, thereby driving the piston to reciprocate in the cylinder. In this process, the volume formed by the piston and the cylinder is constantly changing, and gas is compressed.

Rotary refrigeration compressors use the rotation of the rotor to compress gas. According to their different forms and structures of rotation, they can be divided into screw compressors (single screw compressors and twin screw compressors), scroll compressors, vane compressors, etc.

1.2 Speed Type/Dynamic Compressor

In this type of compressor, the increase in gas pressure is converted from the speed of the gas. In other words, making the inhaling airflow obtain a certain high speed, and then slowing it down, then its momentum is converted into the high pressure gas, which discharges. It can be seen that the compression process in the speed compressor can be performed continuously, and the process is stable.

Speed compressors can be divided into centrifugal compressors, axial compressors, etc. Almost all speed compressors used in refrigeration and heat pump systems are centrifugal compressors.

2. Failure Analysis of the Compressor Not to Start

Figure 3: Refrigeration cycle vector illustration.

If the refrigeration compressor fails to start normally during cold storage running, it will cause a huge cost loss. Therefore, when the refrigeration compressor cannot start, the cause should be found and the problem should be solved in time. Next, let's learn about the reason why the compressor can't start and the correct solution.

The reason why the compressor does not start is mostly the failure of the motor and the electrical control. During maintenance, it is necessary to check various electrical control components, power supply and connection lines.

2.1 Power Line Failure

Fault analysis of power line failure: When the compressor does not start, generally check the power line first to see if the power fuse is blown, the wiring is loose, the disconnection causes a phase loss, or the power supply voltage is too low.

Remedy: When the power supply lacks phase, the motor emits a "buzzing" hum and does not start. After a while, the thermal relay will act and the contacts will open. At this time, you can use a multimeter to check whether the fuse is blown or measure the voltage. If the fuse is blown, replace it with an appropriate one.

2.2 Temperature Controller Failure

Figure 4: Battery temperature controller.

Fault analysis of temperature controller: The refrigerant in the thermal bulb of the temperature controller leaks or the temperature controller fails, which will cause the contact to be normally open. People often ask: would low refrigerant cause compressor not to start? Insufficient refrigerant will cause the compressor to not work.

Remedy: Turn the thermostat knob to see if it can start the compressor at the lowest temperature gear (the largest number or the strong cold continuous operation gear). If it cannot start, further observe whether the refrigerant in the thermal bulb leaks, or the contact action fails, etc. Minor damages can be repaired, but serious ones should be replaced with a new thermostat of the same model and specification.

2.3 Motor Burnt Out or Short Circuit Fault between Turns

Fault analysis of motor burnt out or turn-to-turn short circuit: When the motor winding is burnt out or turn-to-turn short circuit happens, the fuse will often blow repeatedly, especially when the knife switch is pushed on. For open compressors, at this time you can smell the burnt enameled wire from the motor.

Remedy: Please use a multimeter to check whether the motor terminal and the shell are short-circuited, and measure the resistance of each phase. If it is a short circuit or a phase resistance is small, it means that the winding turn-to-turn short circuit happens and the insulation is burned.

During inspection, the insulation resistance can also be measured with an insulation resistance meter. If the resistance is close to zero, the insulation layer has been broken down. If the motor burns out, you should replace it.

2.4 AC Contactor or Intermediate Relay Failure

The failure of an AC contactor or intermediate relay is generally prone to contact overheating, burning, abrasion, etc., which cause poor contact.

Remedy: Please remove, repair or replace them.

2.5 Pressure Controller Failure

Figure 5: Air compressor with pressure gauge.

Failure analysis of the pressure controller: When the pressure value of the pressure controller is improperly adjusted or the spring and other components in the pressure controller fail, the pressure controller will act within the normal pressure range. So the normally closed contact will be disconnected, and the compressor is unable to start.

Remedy: Please open the box cover to see if the contacts can be connected, or use a multimeter to test whether it is connected. After manual reset, if the compressor still cannot start, please check whether the pressure of the system is too high or too low. If the pressure is normal and the pressure controller trips, readjust the high and low pressure control range of the pressure controller or change the pressure controller.

2.6 Thermal Relay Failure

Fault analysis of thermal relay: The contact of thermal relay trips or the heating resistance wire is burnt.

Remedy: When the thermal relay contact trips, first check whether the setting current is appropriate, and press the manual reset button. If the compressor does not trip after starting the compressor, the cause of the overcurrent should be found out. After this problem is solved, press the reset button. When the heating resistance wire is broken, the thermal relay should be replaced.

3. Refrigerator Compressor Not to Start

Figure 6: Diagram of refrigerator internal structure.

Why does my refrigerator compressor not start? Have you ever encountered such a problem? The refrigerator compressor does not start which may be resolved according to the following methods:

First, you need to check whether the power supply of the refrigerator is plugged in or whether the power supply of the refrigerator is loose. The refrigerator is easy to loosen after being used for a long time.

The motor unit of the refrigerator compressor was burned. If this happens, the fuse of the compressor will blow. This is a common problem that the compressor does not start, and it needs to be replaced with a new fuse in time to repair it.

The control circuit of the refrigerator is malfunctioning. The overheating, burning, and abrasion of the contacts will cause the refrigerator's control circuit board to short-circuit and other failures, and even lead to poor contact of the refrigerator compressor contacts. In this case, the circuit board needs to be replaced, and for safety, the electrical plug can also be replaced.

Check whether the circuit voltage of the refrigerator is normal. If the circuit voltage of the refrigerator is lower than the set rated value, the motor of the refrigerator cannot start and will make a "humming" sound.

Refrigerator compressor holding shaft problems are generally caused by lubricating oil. The lubricating oil circuit is blocked, the oil supply is interrupted, or the dirt in the lubricating oil increases the oil’s viscosity. Compressor jamming is due to the small fit clearance between the piston and the cylinder or due to thermal expansion. This situation can usually be solved by dripping lubricating oil.

4. Summary

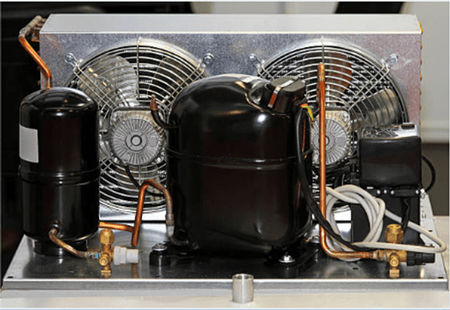

Figure 7: Refrigerator compressor.

In daily life, the compressor should be protected, and regular inspection and maintenance should be carried out to extend its life. When you properly maintain your compressor, it will keep working in a consistent and reliable cooling method for a long time.

Thank you for your reading and more information please visit https://okmarts.com/

OKmarts.com Online Store | We provide leading brands of refrigeration compressors, servo motors, Air cylinder and more all over the world.

CONTACT US

support@okmarts.com

service@okmarts.com

+86-28-84166335