Leading power supply manufacturer, Vicor Corporation, recently evaluated DEK’s award-winning Nano-ProTek stencil nano coating and has reported excellent results. On a densely populated board with multiple 0402, 0201, BGA and micro-BGA components, Nano-ProTek helped improve CpK and yield.

“After attending DEK’s webinar on Nano-ProTek, I decided to benchmark the stencil coating with a very challenging product we are producing,” says Ray Whittier, Senior Process Engineer at Vicor. “There’s always room for process improvement, and I wanted to put Nano-ProTek into practice to find out if it would yield any benefit for us. Suffice it to say, I was pleasantly surprised!”

Using the DEK Horizon 01i print platform, Vicor benchmarked numerous PCB panels, evaluating stencils coated with Nano-ProTek against stencils without the coating. With a circuit size of less than 1” wide by 1.25” long and housing nearly 200 components, the assembly is quite challenging and requires a 501-aperture count stencil. As compared to the non-coated stencils, the Nano-ProTek coated stencils increased transfer efficiency and significantly improved first pass yields.

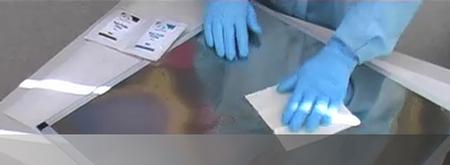

Winner of top industry awards in both Asia and the Americas, DEK’s Nano-ProTek stencil nano coating is a two-part, wipe-on stencil coating that renders the underside of the stencil fluxophobic, keeping flux and the integrated metal solder paste particles from leaching into the stencil web. Nano-ProTek can be quickly applied to new or existing stencils, is remarkably simple to use and, as proven by Vicor, very cost-effective. “When you consider operator and line stoppage costs, the savings we are realizing with Nano-ProTek are considerable,” comments Whittier. “That’s real money and for a per stencil investment of less than $50.00, I think it’s a pretty darn good ROI!”

Brian Lau, DEK Director of Process Support Products and Commercial Management, reiterates Whittier’s comments regarding the effectiveness of Nano-ProTek: “Ray and the team at Vicor have provided further evidence of what we are seeing in manufacturing facilities all over the world,” says Lau. “Nano-ProTek is easy-to-use, extremely affordable and, most importantly, delivers measurable process improvements that translate to big cost savings. Innovation doesn’t have to be complex to be effective and we’ve proven that with Nano-ProTek.”

DEK is a global provider of advanced materials deposition technologies and support solutions including printing equipment platforms, stencils, precision screens and mass imaging processes used across a wide range of applications in electronics pre-placement subassembly, semiconductor wafer manufacture, and alternative energy component production.

Vicor Corporation designs, manufactures and markets modular power components and complete power systems used in the communications, data processing, industrial controls, test equipment, medical and defense electronic markets. Founded in 1981 and headquartered in Andover, Massachusetts, Vicor components are manufactured using highly automated processes in its ISO 9001 registered facilities and are utilized in multiple end-use applications.