GPD Global

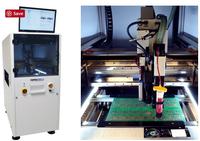

A Manufacturer of High Quality, Precision, Automated Fluid Dispensing and Conformal Coating Systems, SMT Cover Tape Peel Tester and Lead Forming machines for through-hole component preparation.

GPD Global: Applications Overview

GPD Global is an international, state-of-the-art equipment supplier for the PCB assembly and semiconductor industries. We design and manufacture a wide variety of Automatic Fluid Dispensing and Conformal Coating Systems. We also manufacture an SMT Cover Tape Peel Tester and Lead Forming machines for through-hole component preparation. GPD Global also offers great in-depth application service and support from the US to meet dispensing need.

GPD Global is committed to offering premium service to its customers and has sales and customer support affiliates located throughout the world, including: North America, South America, Europe, the Middle East, and Asia-Pacific.

GPD Global has been exporting since 1985 to customers in all parts of the world. The privately owned company exports over 65% of its total sales, its largest growth base represented by Asian customers.

GPD Global Postings

Postings

16 products »

Full-featured and compact benchtop dispense system robot offering accurate and repeatable dispense results! A benchtop dispense system does not mean "no features". The Catalina benchtop dispense system is a ful...

Selective Conformal Coating Systems - Tilt and Rotate

Cost-effective Solutions for Conformal Coating New cost-effective, automated Conformal Coating System (SimpleCoat TR) with tilt and rotate capability and excellent repeatability for just under $4...

High Precision Dispenser - MAX II (Heated Dispenser)

Precision Dispensing System for Heated Dispense Applications The GPD Global MAX II is a compact; high-accuracy system designed for today’s advanced heated dispensing applications. The frame is molded from “liquid rock&rd...

High Precision Dispenser - MAX Series (Non-Heated)

High Precision Dispensers - MAX Series (Non-Heated) Max Series is capable of a wide variety of dispense applications including MicroVolume, Solder Paste and Conductive Adhesive, Underfill, Surface Mount Adhesive, Dam and Fill, Encapsulat...

Large / Versatile Board Processing - DS Series Dispenser

When Applications Require Large Board Processing &/or Versatility The DS Series of dispensers is a robust, large format platform designed to handle all types of applications with ease. Ideal for dispense applications utilizing adhesi...

Benchtop / TableTop Dispensers - Island Series

Simplify Dispensing with GPD Global’s Island Series Dispense Platforms Island Series robots give you versatility to do simple, repetitive automation jobs. Work areas range from 300 mm x 400 mm to 400 mm x 400 mm. All Island Series...

SMT Dispensing Pumps for Integration

Retrofit existing system with Innovative Dispensing Technology for Excellent Dispense Control and Repeatability Advanced pump technologies available for retrofitting include: True Volumetric Pump, Precision Auger Pump, Simplified...

Real Time Process Control for Uniform Fluid Dispensing

Real Time Process Control with FPC: Fluid Pressure Control (Patented) Runs your pump at optimal levels at all times instead of starving or drowning it with inadequate...

Jetting Simplified Jetting pumps are excellent for dispensing small volumes of fluid at high rates of speed. The NCM5000 simplifies jetting to its basic elements - this means easy set up, cleaning, and maintenance for you. The drive syst...

New Advanced Precision Auger Pump - Single Pump Solution The Precision Auger pump is designed to work with mid-to-high viscosity liquid such as glues, conductive, and non-conductive adhesive and pastes. The pump is controlled with...

11 technical articles »

Mar 19, 2024 | GPD Global

Underfill is a composite material usually made of an epoxy polymer that fills gaps between a chip and its carrier or a finished package and the PCB substrate to connect the chip to the board....

Conductive Adhesive Dispensing for Electronic Manufacturing

Sep 07, 2023 | GPD Global, Inc.

A global manufacturer of a broad line of electronic interconnect solutions worked with us to dispense conductive adhesive EpoTek H20E-FC. EpoTek H20E-FC is a two-component, electrically conductive, snap curing epoxy for photovoltaic thin film module stringing, semiconductor packaging and PCB circuit assembly. The primary goal was filling a rectangular cavity on a connector. The epoxy needed to fill the connector to the top of the walls in less than three seconds....

Small Volume Solder Paste Dispensing for Aerospace and Defense

Sep 07, 2023 | GPD Global, Inc.

A repeat customer specializing in high-technology interconnect, sensor, and antenna solutions, partnered with us to dispense small volumes of solder paste (Indium 10.1 SAC305 T6SG 78%m) onto backplane connectors – gold pads 0.175mm x 0.225mm. We performed a test requiring 0.200mm diameter or smaller dots to demonstrate the dispensing capability required....

Staking/Epoxy Adhesive Dispensing for Aerospace

Aug 16, 2023 | GPD Global, Inc.

One of our aerospace customers was looking to automate a few manual operations and asked for suggestions. This customer specializes in assemblies for inflight connectivity for commercial airlines and low orbit satellites. The dispensing process included the application of bonding to the sides of large and small components (4-axis) and the ability to cope with the changing viscosity during processing. The material used was EC-2216 B/A Two Part Epoxy and the largest board size was 12"x10"...

Masking and Underfill Dispensing for Medical Device

Aug 16, 2023 | GPD Global, Inc.

In one of our medical applications projects, the customer wanted to dispense a mask to protect gold leads and an underfill on a silicon substrate with a clear test die. The substrates were Dymax X-499-91-C for Masking and Epoxibond-106M-1 for Underfill Dispensing...

Thermal Interface Material (TIM) Dispensing For Consumer Products

Aug 16, 2023 | GPD Global, Inc.

In one of our Consumer Electronics projects, a leader of networking technologies requested to test dispensing performance of a thermally conductive material, Fujipoly Sarcon SPG-50A. This material improves heat dissipation for higher frequency applications and reduces the negative effects of thermal resistance under heat, cold, humid, and thermal shock conditions. The customer's goal was to dispense a 1mm diameter dot with acceptable speed and consistency....

Underfill Dispensing For Aerospace Military And Defense

Aug 16, 2023 | GPD Global, Inc.

One of our defense customers planned to dispense underfill material for small and large die, using Hysol FP4545FC epoxy encapsulant. This process dissipates stress on solder joints and prevents cracking and fracturing between the bottom of the die and the surface of the substrate....

Solder Paste Dispensing For Aerospace and Defense

Aug 16, 2023 | GPD Global, Inc.

A global aerospace and defense leader requested a capability test of small volume solder paste dispensing on FR4 circuit boards....

LED Encapsulation for Consumer Products

Aug 16, 2023 | GPD Global, Inc.

In one of our Consumer Electronics projects, a smart lighting company wished to dispense silicone-based LED encapsulation material for two different product sizes. The larger product had a 9mm circular dam which required silicone dispensing flush with the top of the dam. The smaller product had a 1mm LED die that required only the top to be encapsulated. The material consisted of two parts which were mixed by weight in a 1:1 ratio. A phosphor powder was added totaling 10% of the overall weight. The phosphor required agitation to remain suspended....

Solder Mask Dispensing For Electronics and Aerostructures

Aug 16, 2023 | GPD Global, Inc.

One of our customers involved with Electronics and Aerostructures requested a test to dispense Techspray Wondermask 2204 solder mask. The dispensing locations include large and small screw holes, single through-hole vias, and connector locations consisting of multiple through-hole vias. The process needed to run quickly and reliably....

58 news releases »

The Latest in Automatic Fluid Dispensing at IPC APEX EXPO 2024

![]() Apr 06, 2024 | Live demos at IPC APEX Expo 2024 – Booth 1504 – April 9-11, 2024, Anaheim, CA

GRAND JUNCTION, CO USA -- April 2024 -- GPD Global – manufacturer of precision fluid dispensing systems for high-volume 24/7, low-volume/high-mix, and R&D production – will exhibit in Booth 1504 at IPC APEX EXPO 2024 on April 9-11 in the Anaheim Convention Center, CA.

Apr 06, 2024 | Live demos at IPC APEX Expo 2024 – Booth 1504 – April 9-11, 2024, Anaheim, CA

GRAND JUNCTION, CO USA -- April 2024 -- GPD Global – manufacturer of precision fluid dispensing systems for high-volume 24/7, low-volume/high-mix, and R&D production – will exhibit in Booth 1504 at IPC APEX EXPO 2024 on April 9-11 in the Anaheim Convention Center, CA.

![]() Aug 01, 2023 | GRAND JUNCTION, CO USA - August 2023 - GPD Global, a manufacturer of precision fluid dispensing systems for high-volume 24/7, low-volume/high-mix, and R&D production is delighted to announce the launch of new website that features a modern design, improved navigation, updated content, and enhanced functionality.

Aug 01, 2023 | GRAND JUNCTION, CO USA - August 2023 - GPD Global, a manufacturer of precision fluid dispensing systems for high-volume 24/7, low-volume/high-mix, and R&D production is delighted to announce the launch of new website that features a modern design, improved navigation, updated content, and enhanced functionality.

GPD Global Places MAX II Precision Dispenser at Universal Instruments' Advanced Process Lab

![]() Dec 17, 2019 | December 17, 2019 – GPD Global has placed a MAX II precision dispenser at Universal's lab in New York (APL).

Dec 17, 2019 | December 17, 2019 – GPD Global has placed a MAX II precision dispenser at Universal's lab in New York (APL).

![]() Jan 09, 2019 | GPD Global will exhibit at IPC APEX EXPO 2019. Stop by Booth 2915 to see live demonstrations of machines and equipment. Experts will be there to discuss your production needs. Whether your project requires a pump for retrofitting or a fully automated dispense system, conformal coating, or component preparation, we have a solution for you.

Jan 09, 2019 | GPD Global will exhibit at IPC APEX EXPO 2019. Stop by Booth 2915 to see live demonstrations of machines and equipment. Experts will be there to discuss your production needs. Whether your project requires a pump for retrofitting or a fully automated dispense system, conformal coating, or component preparation, we have a solution for you.

Conformal Coating & Latest Dispense Technology at SMTAI

![]() Oct 08, 2018 | GPD Global will exhibit at the upcoming SMTA International 2018. At booth# 517, see our automated Conformal Coating Machine with excellent repeatability for under $40,000.

Oct 08, 2018 | GPD Global will exhibit at the upcoming SMTA International 2018. At booth# 517, see our automated Conformal Coating Machine with excellent repeatability for under $40,000.

Tabletop Robot for Precision Dispensing

![]() Sep 06, 2018 | GPD Global offers the ideal tabletop robots (Catalina Series) for precision dispensing.

Sep 06, 2018 | GPD Global offers the ideal tabletop robots (Catalina Series) for precision dispensing.

NEW Benchtop Dispensing Robot!

![]() Feb 12, 2018 | GPD Global introduces its NEW full-featured benchtop dispensing robot system: Catalina. A benchtop system does not mean "no features". This compact and efficient semi-auto dispense robot provides you with numerous standard features: automatic vision, laser surface sensing, and automatic nozzle alignment and calibration.

Feb 12, 2018 | GPD Global introduces its NEW full-featured benchtop dispensing robot system: Catalina. A benchtop system does not mean "no features". This compact and efficient semi-auto dispense robot provides you with numerous standard features: automatic vision, laser surface sensing, and automatic nozzle alignment and calibration.

Conformal Coating System For Under $40,000!!!

![]() Nov 07, 2017 | GPD Global offers a cost-effective, automated Conformal Coating System (SimpleCoat) with excellent repeatability for just under $40,000!!!

Nov 07, 2017 | GPD Global offers a cost-effective, automated Conformal Coating System (SimpleCoat) with excellent repeatability for just under $40,000!!!

Latest Dispense Technology for Integration and Retrofit

![]() Oct 02, 2017 | GPD Global will exhibit at the upcoming IMAPS 2017. At booth 244, GPD Global will exhibit a complete line of Fluid Dispensing pumps with the latest dispense technologies for integration or retrofit. Whether your process requires low or high viscosity fluids, thick pastes, or abrasive media, there is a dispense pump to meet your requirements.

Oct 02, 2017 | GPD Global will exhibit at the upcoming IMAPS 2017. At booth 244, GPD Global will exhibit a complete line of Fluid Dispensing pumps with the latest dispense technologies for integration or retrofit. Whether your process requires low or high viscosity fluids, thick pastes, or abrasive media, there is a dispense pump to meet your requirements.

Conformal Coating & the Latest Dispense Technology at SMTAI

![]() Sep 07, 2017 | GPD Global will exhibit at the upcoming SMTA International 2017. At booth# 216, on display is an automated Conformal Coating Machine with excellent repeatability for under $40,000. SimpleCoat is a NEW low cost, inline, simple Conformal Coating System with full featured programming making the conformal coating processes quick and easy to set up.

Sep 07, 2017 | GPD Global will exhibit at the upcoming SMTA International 2017. At booth# 216, on display is an automated Conformal Coating Machine with excellent repeatability for under $40,000. SimpleCoat is a NEW low cost, inline, simple Conformal Coating System with full featured programming making the conformal coating processes quick and easy to set up.