AWgage-150 Metal Film Metrology

Company Information:

Name: |

AWgage-150 Metal Film Metrology |

Category: |

|

Offered by: |

|

AWgage-150 Metal Film Metrology Description:

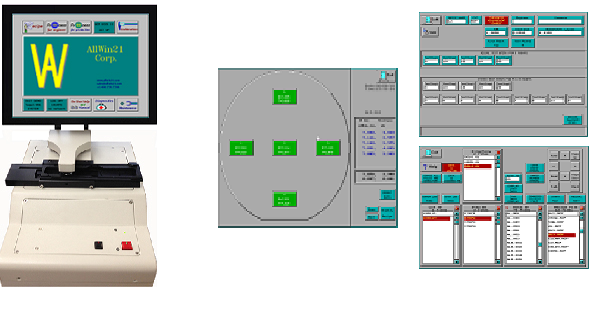

AWgage-150 measures sheet resistance in ohms per square or milliohms per square. If specific resistivity is known, the thickness of the deposited film layer can be computed from the sheet resistance. The choice of measurement data is easily get in the software. AWgage-150 can accommodate 150mm (6") wafers as well as the standard 2", 3",4", 5" wafers without any hardware change.

Key Features:

- 30 years proven Eddy Sheet Resistance Measurement technology.

- Non-contact Sheet Resistance Measurement.

- W/square to 19,990W/square sheet resistance measurement range.

- 100Å to 270kÅ Metal Film Thickness range.

- Touch Screen Monitor GUI and PC w/ Advanced Allwin21 software.

- Wafer carriage travel programmed with internal encoder step motor , without encoder disk.

- Consistent wafer-to-wafer process cycle repeatability.

- Small footprint and energy efficient.

- Made in U.S.A.

Configuration:

- Main Frame

- Wafer Carriage (2”-6”)

- Measurement Head

- RF Tank Circuit board

- Pentium® class computer board

- Main control board

- Motor control board.

- Two USB Ports

- Two Extra DB9 Ports

- 15–inch touch screen GUI

- Allwin21 Corp proprietary software package.

- Mouse & keyboard .

- USB Flash Drive with AW Software backup.

- CE Certification (Optional)

Specifications:

- Perform odd number of site tests: 1 to 9 points

- Highly Conductive or Metal Sheet Resistance

1 to 1,999 mW/square

1 to 1,999 W/square

10 to 19,990 W/square

- Highly Conductive or Metal Film Thickness

Minimum: 100 Ångström

Maximum: Proportional to resistivity. Maximum for a resistivity of 2.7 mW-cm is 270 k Å (27 mm)

- Sheet Resistance Repeatability

Total repeatability is the standard deviation (s) percent of mean value(X),1 count.

Range s/X (±%)

1 to 100 mW/sq; W/sq 1

100 to 500 mW/sq; W/sq 2

500 to 1000 mW/sq; W/sq 4

1000 to 1,999 mW/sq; W/sq 6

1,999 to 5,000 W/sq Consult Factory

5000 to 10,000 W/sq Consult Factory

10,000 to 15,000 W/sq Consult Factory

Software Features:

The AWgage-150 system is controlled by menu commands from the control software. This software allows a great deal of flexibility and control of the Allwin21 system. The AWgage-150 control software features the following:

- Automated calibration of all subsystems from within the control software. This allows faster and easier calibration, leading to enhanced process results. The AWgage-150 allows calibration of the ohm and milliohm measurements within the software for maximum performance and accuracy. This provides a much easier and faster method to calibrate the instrument than by adjusting pots on the back of the traditional Sheet Resistance Measurement Instrument.

- The SOFTWARE can compensate for where the flat is on the carriage to locate the test points.

- It features a recipe editor to create and edit recipes to fully automate the processing of wafers on the Allwin21 system.

- Validation of the recipe so improper points will be revealed.

- Storage of multiple recipes, process data and calibration files so that process and calibration results can be maintained and compared over time.

- Passwords provide security for the system, recipe editing, diagnostics, calibration and setup functions.

- Simple and easy to use menu screens which allow an automatic cycle to be easily defined and executed.

- Troubleshooting features which allow engineers and service personnel to activate individual subassemblies and functions.

AWgage-150 Metal Film Metrology was added in Nov 2015

AWgage-150 Metal Film Metrology has been viewed 406 times

7 More Products from Allwin21 Corp. :