SMT Offline AOI Inspection Machine ZW 500

Company Information:

Name: |

SMT Offline AOI Inspection Machine ZW 500 |

Category: |

|

Offered by: |

|

SMT Offline AOI Inspection Machine ZW 500 Description:

SMT Offline AOI Inspection Machine ZW 500

Dimension:900*1100*1350 mm

PCB width:30x30-450x330mm

Inspection Component: 0402 chip

Weight:Aprox. 450kg

Product description: SMT Offline AOI Inspection Machine ZW 500, Dimension:900*1100*1350 mm, PCB width:30x30-450x330mm, Inspection Component: 0402 chip, Weight:Aprox. 450kg

SMT Offline AOI Inspection Machine ZW 500

The vector analysis algorithm and the multiple detection algorithms are combined to achieve the best detection side capability.

The full version matches multiple pieces of detection at any position.

Smart camera barcode recognition system (identifying 1D code and 2D code).

Multi-line monitoring system, all production line production status is clear at a glance.

The remote programming and debugging control functions are used together, and the software control performance is stronger.

Multifunctional high precision new algorithm new interface

Custom IPE separately assigns light sources based on current components

Users can customize the image source with simple expressions, and different algorithms can combine different effects, which can greatly improve the detection rate and reduce the false positive rate. The image source in the Qubit AOI system can understand the dot matrix of pixels. Each pixel is represented by data from 1 to 4 channels. The IPE expression can independently calculate each pixel in the image source to generate a new image.

Full-page detection.

Multi-piece detection function for any position of the entire PCB.

More intuitive and fast NG OK image.

The programming interface of the introduction, regardless of the PCB size, the PCB is in the visible range.

Imported servo control system

All major components are made of internationally renowned brands, with high service life and low failure rate under the premise of ensuring the running stability and motion accuracy of the equipment.

With high color reproduction effect, combined with high-resolution and high-definition optical telecentric lens, the product has high discrimination and high-definition image, providing high-definition image output for AOI equipment.

5.0M pixel-level telecentric optical lens.

Based on its unique optical properties: high resolution, ultra-wide depth of field, ultra-low distortion and unique parallel light design, it brings a qualitative leap to machine vision precision inspection.

Inspection System & Optical System

|

category |

project |

Specifications |

||

|

Optical system |

Camera |

5 million Gigabit network color high speed camera |

||

|

Resolution |

10/15/20 micron/dot (optional) comes standard with 15 micron/point (corresponding to FOV: 36mm*30mm) |

|||

|

Optical lens |

5.0M pixel telecentric lens, depth of field: 8mm - 10mm |

|||

|

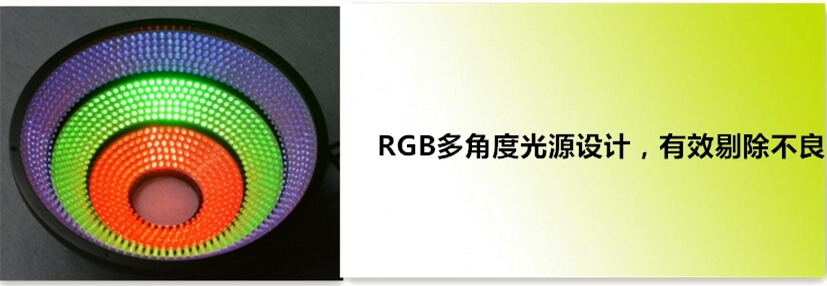

Light source system |

RGB ring multi-angle LED structure light source |

|||

|

Light source control system |

Digital constant current controller |

|||

|

Image processing speed |

FOV processing speed |

<170 milliseconds |

||

|

Movement speed |

Up to 700 milliseconds |

|||

|

Detection speed |

3500 square millimeters / second |

|||

|

Characteristics |

IPE is an abbreviation of Image Processing Expression, which allows users to customize the image source with simple expressions. Different algorithms can combine different effects, which can greatly improve the detection rate and reduce the false positive rate. The image source in the Qubit AOI system can understand the dot matrix of pixels. Each pixel is represented by data from 1 to 4 channels. The IPE expression can independently calculate each pixel in the image source to generate a new image. Can detect multiple pieces anywhere in the class |

|||

|

operating |

Graphical offline programming and debugging, accurate automatic positioning of micron, fast process, support for remote offline debugging, does not affect the normal test of equipment |

|||

|

Mark |

Points |

2 common Mark points can be selected to automatically correct the horizontal Mark |

||

|

Test content |

Solder paste printing |

Skew, Wuxi, Shaoxi, Duoxi, Open circuit, pollution, bridging |

||

|

Patch |

Missing parts, offset, skew, tombstone, side stand, flip, polarity reverse, wrong piece, breakage, pollution, bridging, multiple pieces of IC bending foot |

|||

|

After reflow soldering |

Missing parts, offset, skew, tombstone, side stand, flip, polarity reverse, wrong piece, broken, pollution, Wuxi, Shaoxi, multi-tin, fake welding, solder ball IC bending position any position |

|||

|

After wave soldering |

Insert needle, Wuxi, Shaoxi, Duoxi, fake solder, tin bead, tin hole, short circuit, multiple pieces in any position |

|||

|

Red rubber board |

Missing parts, offset, skew, tombstone, side stand, flip, polarity reverse, wrong piece, broken, Yijiao, multiple pieces in any position |

|||

|

PCB size |

30 × 30 mm ~ 450 × 330 mm (can be customized according to customer requirements) |

|||

|

P CB thickness |

0.3 mm to 6 mm |

|||

|

PCB warpage |

≤6 mm (with fixture-assisted correction) to eliminate the effects of PCB deformation (special requirements can be customized) |

|||

|

Part height |

The net height of ≤35mm is ≤70mm (special requirements can be customized) |

|||

|

Minimum part |

01005 components, 0.3 mm pitch and above IC |

|||

|

X, Y platform |

Drive device |

AC servo motor system |

||

|

Precise positioning |

≤8 microns |

|||

|

Y marble platform |

Precise positioning |

≤6 microns |

||

|

Control System |

operating system |

Windows8-64Bit |

||

|

Computer host |

I5 CPU, 8G, GPU graphics, 16G RAM, 128G solid state drive, 1TB mechanical hard drive |

|||

|

monitor |

22-inch LCD widescreen display |

|||

|

Other parameters |

Mechanical dimensions |

90 cm × 110 cm × 135 cm (height with feet) |

||

|

weight |

About 450 kg |

|||

|

power supply |

AC 220 volts ± 10%, frequency 50/60HZ, rated power 600W |

|||

Keywords:

SMT Inspection Machine, SMT AOI Machine, Offline AOI Machine, Online AOI Machine, SMT X Ray Machine, SMT SPI Machine, Offline SPI Machine, 3D SPI Machine, 3D AOI Machine, Solder Paste Inspection Machine, SMT Flying Probe Testing Machine, SMT In-Circuit Tester, Koh Young SPI/AOI, JUKI AOI/SPI, SAKI AOI, Omron SPI/AOI

Professional SMT machine supplier. If you have any needs, please contact us.

Hanwha Pick and Place Machine:XM520, HM520, HM510, Excen PRO, Decan S2, Decan S1, SM485P, SM482 Plus, SM481 Plus, SM471 Plus

Yamaha Pick and Place Machine: YRM20DL, YRM20, YSM40R, YSM20R, YSM20WR, YSM10, F8S, YS12F, YG12, YG100RA, YS24F

JUKI Pick and Place Machine: LX-8, RX-8, RX-7R, RX-7, RS-1R, RS-1, RS-1XL,JM-20, JM-100, FX-3RA, KE-3010A, KE-3020VA

Panasonic Pick and Place Machine: NPM-GH, NPM-DX, NPM-D3A, NPM-D3, NPM-WX/WXS, NPM-TT2, AM100, VM101, VM102

FUJI Pick and Place Machine: AIMEX III, AIMEX R, NXT III, NXTR-S, NXTR-A, NXT M6 III, NXT M6 Ⅱ, NXT M3 III, NXT M3 Ⅱ,

Siemens Chip Mounter: SIPLACE XS Series, SIPLACE SX Series, Siplace DX Series, SIPLACE TX Series,

SMT Stencil Printer: GKG, DEK, JUKI, FUJI, Yamaha, Panasonic, SMT Glue Dispenser, Semi-Auto stencil printer,

SMT Reflow oven: 6 Zones, 8 Zones, 10 Zones, 12 Zones, Heller, Ersa, JT

Insert Plug-in machine: Hanwha, JUKI, Yamaha, Panasonic, Offline Insert Plug-in machine, Vertical Plug-in machine, Heterotypic Plug-in machine

Wave Soldering Machine: Dual Rail Wave Soldering Machine, lead free Wave Soldering Machine, Nitrogen Wave Soldering Machine, Selective Soldering Machine, Ersa Wave Soldering Machine, JT Wave Soldering Machine

SMT Inspection machine: Saki SPI/AOI, Koh Young SPI/AOI, JUKI SPI/AOI, Omron SPI/AOI, Yamaha SPI/AOI, Flying Probe Testing Machine, X-Ray Inspection Machine, In-Circuit Tester,

SMT Peripheral Equipment: PCB Loader, PCB Unloader, PCB Conveyor, PCB Transfer Shuttle Conveyor, Auto BGA Rework Station, PCB loader Buffer Stocker, PCB Cleaning Machine, SMT Nozzle Cleaning Machine, PCB Separator Depanelizer Machine, Automatic inline Labelling Machine, SMT Screen Developing and Stripping Machine, SMT Ionic Contamination Tester, SMT Camera Module Cleaning Machine, Reflow Oven Cooler Cleaning Machine, SMT Fixture Cleaning Machine, PCB Stencil Cleaning Machine, PCB Laser Marking Machine, PCB Circuit Repair Machine, Thermal Profiler for reflow oven,

SMT Spare Parts: JUKI Feeder, Yamaha Feeder, Panasonic Feeder, Sansung/Hanwha Feeder, FUJI Feeder, Seimens Feeder, Mydata Mycronic Feeder, Feeder Storage Cart, Tray Feeder, Feeder Calibration jigs, JUKI Nozzle, Yamaha Nozzle, Panasonic Nozzle, Samsung/Hanwha Nozzle, FUJI Nozzle, Universal GSM Nozzle, Siemens SIPLACE ASM Nozzle, Mydata Nozzle, JUKI Spare parts, Yamaha Spare parts, Panasonic Spare parts, Samsung/Hanwha Spare parts, Siemens Spare Parts, FUJI Spare Parts, Mycronic Spare Parts,

SMT WORKSHOP LINE: SMT LOADER+ SMT printer+ SMT SPI+ SMT chip mounter+ SMT reflow oven

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen China Tel: +86 -137 14564591 Skype:sales@effsmt.com E-mail:sales@effsmt.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / phone /Wechat online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

SMT Offline AOI Inspection Machine ZW 500 was added in Jan 2024

SMT Offline AOI Inspection Machine ZW 500 has been viewed 14 times

20 More Products from Efficient Technology Co., Ltd :

.gif)