No damage X-ray detecting system SMT Battery IC inner circuit X ray inspecting machine X7600

Company Information:

Name: |

No damage X-ray detecting system SMT Battery IC inner circuit X ray inspecting machine X7600 |

Category: |

|

Offered by: |

|

No damage X-ray detecting system SMT Battery IC inner circuit X ray inspecting machine X7600 Description:

No damage X-ray detecting system SMT Battery IC inner circuit X ray inspecting machine X7600

Customized X-ray inspect solution for your products, you are welcome to contact Rita Li by Whatsapp/Wechat/Viber:0086-134 3448 1030

Microfocus X-ray inspection machine X-7600 introduction: -CT X-7600 X-ray machine Specification:

1. X-ray tube type: Closed

2. Max tube voltage: 130KV, other voltage X-RAY tube please contact us.

3. Max tube current: 200μA.

4. Focal spot size: 3μm

5. Magnification: Geometric magnification: 200X

System magnification: 1000X

6. Detector speed: 35FPS

7. Detector resolution: 1500*1500

8. Detector inclined angle: 60°obeservation tilt

9. Table size: 500*500mm

10. Table: 360°rotation.

11. Input voltage: AC 110-220V(±10%)

12. X-ray leakage: ≤1usv/h

X-ray

X-6600A X-ray machine Feature:

1. High-definition image.

2. 6axis linkage system.

3. 2.3 million high resolution digital flat panel detector.

4. 60 degrees observation, platform 360 degreesrotation.

5. Color image navigation & Mapping navigation

6.Automatic programming detection and automatic analysis OK/ NG(Optional).

7. Mapping Mosaic Function.(Optional).

8. Scalable 3D module( industrial CT)(Optional)

9. Programmable detection. ( Optional)

Application of microfocus X-ray inspection machine: -CT X-ray

X-Ray inspection system is a type of high-precision detection equipment. It inspects and analyzes the inner structure of the object via the penetration power from X-Ray without damage. It is also called as non destructive testing machines.

It has been widely applied to BGA detection, LED, SMT, semiconductor, battery,automotive electronics, ceramic products,casting, plastic, connectors , pharmaceutical products and other industries.

Full Automatic Testing Procedures-CT X-ray

Click programming without the need for operator intervention on the component can detect automatically.

Warmly welcome to send us your sample that need to analyse, we’ll offer the free testing report for your sample.

Seamark X-ray machine FREE training in Singapore:

Seamark X-ray leakage amount: ≤1 u Sv/hr

Please noted that the Radiation Detection Report is according to which 21 CFR Subchapter J is applicable.

-CT X-ray

The international acceptable standard is <1 uSv/hr. The X-6600 machine actual radiation reading is 0.3 uSv/hr which is same as the environment normal rate. So it is qualified.

X-ray Machine FREE Training service for our customers:

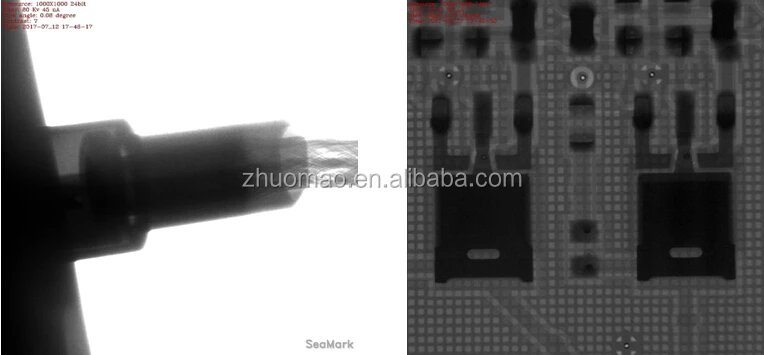

Microfocus X-ray inspection machine X-7600 detection effect photos: -CT X-ray

Aluminum Die Casting inspection:

Aerospace Parts inspections:

Car Spareparts inspection:

Workshop for the X-ray inspection machine:

Microfocus X-ray inspection machine working principle: -CT X-ray

X-ray inspection machine quality: -CT X-ray

Seamark X-ray machine are all adopted the highest quality spare parts, the core spare parts are imported from oversea:

X-ray closed tube ---imported from the Japan

High definition flat panel detector---imported from Korea

Microfocus X-ray inspection machine specific application:

1)Defect inspection in IC encapsulation, e.g.: layer separation, cracking, void, and line integrity.

2)Measuring chip size, measuring line curvature, measuring the proportion of solder areaof components.

3) Possible defects in printed circuit board manufacturing processes, e.g.:misalignment,solder bridge and open etc.

4) SMT solder short, cold solder, component shifted, solder insufficient, solder void inspection andmeasurement.

5) Defect inspection of open, short or abnormal connections that may occur in automotive wiring harnesses and connectors.

6) Inner rupture or hollow inspection in plastic or metal.

7) Battery stacking uniformity, electrode welding inspection.

8) Seed, biological material inspection etc.

Our Service:

1. Training: Free training and installation for all types of Microfocus X-ray inspection machine.

2. Warranty: We offer free warrantywithin the first year, after the first year, the spare parts and service fees will be on buyers account.

3. Services hours: Before-sales and after-sales services is 24hours/7days. Your inquiry will be replied within8 hours.

4. Customized service: Can provide customized services according to customers’ requirement.

5. Give great discount to AGENCYto ensure agents profit.

Seamark X-ray Machine FREE Training in Canada:

Seamark X-ray Machine FREE Training in Portugal:

Seamark X-ray Machine FREE Training in Germany:

Packing & Shipping of X-ray inspection machine:

1. Standard export wooden package for X-ray inspection machine.

2. Delivery within 10 business days after payment confirm;

3. Shipping by sea to your nearest seaport.

4. Loading Port: Shenzhen.

Customer feedback:

Customers are satisfied with our X-ray inspection system.

Seamark X-ray inspection machine are very easy to learn and operate, it is withsmart Seamark X-ray software.

Are you still hesitate to get the X-ray machine? Contact us to know more about it. : ) Time is very valuable.

WHY CHOOSE US:

Our advantage:

1. 13 years experience of LED BGA SMD rework station and X-ray inspection machine.

2. All X-RAY models with CE and FDA approved.

3. High reputation around the world.

4. Professional service and technology support.

5. Competitive price with good quality.

Welcome to contact us to discuss with us the X-ray machine you want, we’ll be glad to accept customized order.

No damage X-ray detecting system SMT Battery IC inner circuit X ray inspecting machine X7600 was added in Jun 2018

No damage X-ray detecting system SMT Battery IC inner circuit X ray inspecting machine X7600 has been viewed 899 times

20 More Products from Seamark Zhuomao Photoeletric technology(Shenzhen)CO., ltd :

.jpg)

1.png)