BEST Inc.

BEST offers professional rework, repair and prototype builds of PCBs. Our expertise is on BGA rework and QFN rework. Our experienced instructors teach professional soldering classes as we are an IPC certified training center

Consultant / Service Provider, Manufacturer

Your BEST Source for PCB rework/repair, solder training, and soldering tools!

Our Contract BGA Rework/Repair Division provides expert bga rework services and bga repair, ECO modifications and rework to your PCBs. Our state of the art equipment and IPC certified operators insure the bga rework done on your PCBs will be done correctly and reliably. 100% guaranteed. Because our core competency is BGA rework & PCB repair, our operators' output per person far exceeds that of in-house operators. Compare your fully burdened overhead rate of rework/repair to our per board price - you'll be surprised! We offer turns as quick as 24 hours on BGA rework and reballing of BGAs.

BEST is an IPC Master Certification Center offering Instructor and Operator soldering courses for IPC-A-610, J-STD-001, IPC 7711/7721 as well as customized classes to meet specific standards or criteria. BEST now offers the first web based, fully interactive IPCA-610 Certification online! BEST is also the only IPC Certification Center in the world with a Mobile Training Center - a fully operational, mobile solder training lab that brings the classroom right to your door!

Pre-order your copy of the IPC A-610D Acceptability of Electronic Assemblies Standard, due to be released in February, 2005. Order yours today from BEST!

BEST, Inc specializes in offering products that streamline the process of hand soldering, rework and repair, which also includes lead free soldering products. Our training kits, dummy components and IPC materials are excellent resources for skill building and retention. Our Rework/Repair Exchange offers product reviews and technical articles on the latest rework/repair equipment, as well as a forum to buy and sell used or refurbished equipment.

BEST Inc. Postings

74 products »

The IPC-J-STD-001H is a gloablly recognized and accepted assembluy standard for printed circuit boards as it spells out the criteria on soldering processes and materials. This version was updated in late fall of 2020 and b...

The IPC-J-STD-001H is a gloablly recognized and accepted assembluy standard for printed circuit boards as it spells out the criteria on soldering processes and materials. This version was updated in late fall of 2020 and b...

IPC-A-610H Standard Printed Copy

The IPC-A-610H Acceptability of Electronic Assemblies has been updated to the latest revision. This version has been updated from the previous revision through the addition of several specifications, changing the locatio...

BEST Inc.’scomponent ID poster is designed to be used in your training area. The poster displays a variety of components so that instructors can teach the nomenclature or language of electronic circuit board components,...

Magnetic Steel Flex, Rigid Flex and ioT Fixture

BEST Inc. design and fabricates magnetic fixtures for ioT, flex and rigid-flex applications. Made frommagnetized steel, these fixtures are designed and fabricated to hold flat flex circuits. They can be used for pick and place, coating,...

Custom ESD Packaging for Electronics

BEST Inc. can provide your custom foam cutting insert needs. Whether you have an anti-static (pink) closed or open foam packaging material or other kind of foam that needs to be cut-BEST Inc. can be your source. Once you have the materials in hand...

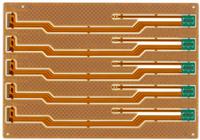

Flex and Rigid-Flex Depanelization Services

Laser depanelization services from BEST Inc. feature precision cutting and depanelization cut out of flex and rigid flex materials. These materials a combination of Katon(TM), copper and rigid board material. After sending us the GERBER...

Precision Cut Kapton shields, gaskets or washers

BEST Inc. has been providing laser machined parts for the electronics industry for many years with both Kapton(TM) as well as as adhesive-backed Kapton (TM) shapes per customer requirements. These parts are being used as heat shields, spacers and...

IPC J-STD-001 Certification For Specialist | IPC JSTD Certification

IPC J-STD-001 Certification is a 5-day program for experienced soldering technicians looking for acquaintance of the IPC J-STD-001 Document and process controls and recommendations surrounding “best practices” in this document. The cou...

IPC J-STD-001 Certification For Instructor And Recertification

This is a 2-day examine course is for anyone needing to renew their existing IPC J-STD-001 certification for the instructor. Attendees will review the J-STD-001 standard and successfully complete both the closed and open book exams including lead...

20 technical articles »

Hand Printing using Nanocoated and other High End Stencil Materials

May 29, 2019 | Bob Wettermann

There are times when a PCB prototype needs to be built quickly to test out a design. In such cases where it is known early on that there will be multiple iterations or that a "one and done" assembly will be made that there will be some SMT assemblers who choose to hand print solder paste onto the board using a "frameless" stencil. In such cases where hand printing is used, the consistency of the printing technique has typically been in question. Furthermore, the effectiveness of both the nanocoatings as well as the higher end stainless steel materials, which have been heretofore studied in controlled printing environments, will be evaluated for their impact on the hand printing process.</p><p>The purpose of the study was to determine the effectiveness of select nanocoating materials as well as certain high end stainless steel stencil materials as they relate to the manual SMT printing process. A variety of nanocoatings were applied to SMT metal stencils and solder paste volume measurements were taken to compare the effectiveness....

Solder Paste for BGA Rework | Multiple Methods for Applying Paste Flux

Mar 30, 2017 | Bob Wettermann, BEST Inc. MIT

There are multiple methods, each with its associated benefits for given applications, for printing either solder paste or paste flux for BGA rework. Each of these methods is best-suited for a given situation, board layout and skill level of operators performing the BGA rework. This discussion will layout the various methods and present the specific circumstances for which the specific technique is most wellsuited. In addition, the pluses and minuses for each of the approaches will be discussed in detail....

Feb 01, 2017 | Bob Wettermann

BGA Rework Course encompasses the skills necessary to perform rework of electronic printed circuit boards to include PBGA and CBGA technologies. There should be 'one-stop' solution, that offers a wide range of ball grid array rework and repair services....

PCB Laser Depanelizing Using a UV Laser

Oct 06, 2016 | Bob Wettermann

One of the methods gaining in popularity for singulating rigid/flex, rigid and flex circuit boards post assembly is through the use of laser routing. This method has the advantage of speed, positional accuracy, no tooling wear and lastly no induced mechanical stresses on components during the singulating process....

Adhesive Backed Plastic Stencils vs Mini Metal Stencils

Aug 27, 2015 | Bob Wettermann, MIT

Ever since there has been a widespread usage of surface mount parts, the trend of continued shrinkage of devices with ever finer pitches has continued to challenge PCB assemblers for the rework of same. Todays' pitches are commonly 0.5 to 0.4mm with packages of tiny outline sizes, 5 -10mm square, making the rework of such devices a challenge. In addition to the handling and inspection challenges comes the board density. Spacing to neighboring components continues to be compressed so the rework techniques should not damage neighboring components....

Plastic vs Metal Stencils for Prototype Printing

Sep 11, 2014 | Bob Wettermann.

This article goes through the pluses and minuses of using plastic stencils for DIY prototypes. The release efficiency is measured and "rules of thumb" for using one type vs another is explained....

Sep 11, 2014 | CRANE.

In this DOD study the reliability of reworked QFNs is studied with the outcome being that a stay in place stencil does not impact the reliability of a QFN reworked using this technique...

Reballing a QFN Simplifies QFN Rework

Sep 11, 2014 | Bob Wettermann.

There are a variety of methods one can use to rework QFNs. This paper explains one of the ways to get very little center ground voiding while making it easy to place a tiny component with almost no keep out areas....

Performance of Kapton Stencils vs Stainless Steel Stencils for Prototype Printing Volumes Processes

Jul 03, 2013 | Bob Wettermann, Hung Hoang

It has been demonstrated in numerous pieces of work that stencil printing, one of the most complex PCB assembly processes, is one of the largest contributors to defects (Revelino et el). This complexity extends to prototype builds where a small number of boards need to be assembled quickly and reliably. Stencil printing is becoming increasingly challenging as packages shrink in size, increase in lead count and require closer lead spacing (finer pitch). Prototype SMT assembly can be further divided between industrial and commercial work and the DIYer, hobbyist or researcher groups. This second group is highly price sensitive when it comes to the materials used for the board assembly as their funds are sourced from personal or research monies as opposed to company funds. This has led to development of a lower cost SMT printing stencil made from plastic film as opposed to the more traditional stainless steel stencil used by industrial and commercial users.This study compares the performance of these two traditional materials and their respective impact on solder paste printing including efficiency and print quality....

Component Shortages Causing Electronics Manufacturers to "Use All Means Necessary" to Ship Products

Nov 24, 2010 | Bob Wettermann

As the electronics manufacturing and assembly industry in the US recovers to some degree from the economic crisis which began in 2008, the challenge of component shortages has risen to the top as one of the stumbling blocks for contract assemblers and cap...

35 news releases »

Custom SRT and Hot Air Nozzles

![]() May 12, 2019 | Fast Shipment of Custom SRT Nozzles

May 12, 2019 | Fast Shipment of Custom SRT Nozzles

High mix Low Volume Technical Webinar

![]() Oct 23, 2018 | Best practice webinar for high mix low volume assemblers

Oct 23, 2018 | Best practice webinar for high mix low volume assemblers

New Product Launched Component ID Poster for Electronics Training

![]() Aug 17, 2018 | New Component ID Poster for electronics training and certification.

Aug 17, 2018 | New Component ID Poster for electronics training and certification.

![]() Jun 15, 2018 | BEST Inc launches the release of a company capabilities video. The story of how EMS and wire harness and electronics companies can be serviced by BEST Inc. is told in a fun and compelling way.

Jun 15, 2018 | BEST Inc launches the release of a company capabilities video. The story of how EMS and wire harness and electronics companies can be serviced by BEST Inc. is told in a fun and compelling way.

BEST Announces Availability of Custom Electronics Packaging

![]() Mar 20, 2018 | BEST Inc announces the availability of a custom ESD packaging service for electronic assemblies and components.

Mar 20, 2018 | BEST Inc announces the availability of a custom ESD packaging service for electronic assemblies and components.

![]() Nov 25, 2017 | A-610 and J-STD-001 has recently been updated. This webinar will highlight the changes in the standards

Nov 25, 2017 | A-610 and J-STD-001 has recently been updated. This webinar will highlight the changes in the standards

New Sustainable J-STD-001 Soldering Kit

![]() Oct 03, 2017 | BEST releases new version of J-STD-001 training kit that can be refilled.

Oct 03, 2017 | BEST releases new version of J-STD-001 training kit that can be refilled.

New Sustainable J-STD-001 Soldering Kit

![]() Oct 03, 2017 | BEST releases new version of J-STD-001 training kit that can be refilled.

Oct 03, 2017 | BEST releases new version of J-STD-001 training kit that can be refilled.

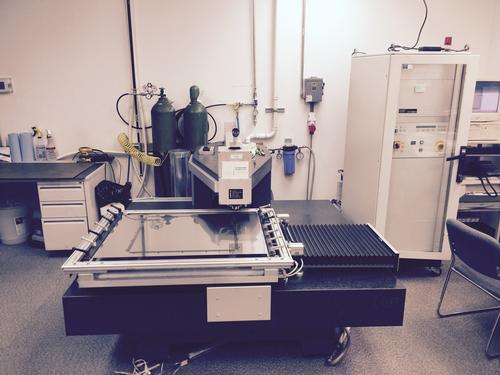

BEST Inc. Puts Semi-Automated Mass PCB Rework Process Online

![]() Mar 31, 2017 | BEST installs and brings Up mass rework machine capability to reduce costs and increase the turnover of boards requiring lots of parts change outs.

Mar 31, 2017 | BEST installs and brings Up mass rework machine capability to reduce costs and increase the turnover of boards requiring lots of parts change outs.

BEST SMT Boot Camp Nov 29-Dec 1, 2016 Featuring Phil Zarrow

![]() Oct 25, 2016 | Learn about SMT assembly from SME Phil Zarrow in Chicago

Oct 25, 2016 | Learn about SMT assembly from SME Phil Zarrow in Chicago