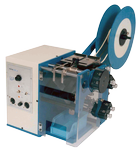

Large / Versatile Board Processing - DS Series Dispenser

Company Information:

Name: |

Large / Versatile Board Processing - DS Series Dispenser |

Category: |

|

Offered by: |

|

|

View Large / Versatile Board Processing - DS Series Dispenser |

Large / Versatile Board Processing - DS Series Dispenser Description:

Contour Mapping for Precision Fluid Dispense

When Applications Require Large Board Processing &/or Versatility

The DS Series of dispensers is a robust, large format platform designed to handle all types of applications with ease. Ideal for dispense applications utilizing adhesive, solder paste, conductive adhesive, potting compounds, and more.

Common Applications: Solder Paste, Conductive Adhesive, SMT Adhesive, LED Encapsulation, Potting Compounds, Underfill, Dam & Fill, COB Encapsulation

For the utmost in versatility and capability the DS Series is able to handle up to 3 different dispense pumps. The system is able to toggle between each of the pumps in a single program. DS Series systems are compatible with all GPD Global dispense pumps (Precision Auger Pump, Jetting Pump (NCM5000), Volumetric Pump (PCD), Time Pressure)

The DS Series is highlighted by its large work area, up to 24" x 24" (610 mm x 610 mm), the largest standard platform in the industry. Available in standalone or inline it can be configured to meet your production needs. Standalone systems are configured with a flat worktable and board crowders that hold the product to a registered location. For additional support, the worktable may have vacuum ports or support custom fixturing. Inline configurations include an Entrance, Work Area, and Exit zone. Each zone is configured with a board stop and product present sensors to track the product through the system.

For applications requiring heat, the work table on standalone systems may be heated to 200° C. All three zones of a conveyor inline configuration may be heated via convection or conduction. Pumps may also have heat applied for fluid that performs better under an elevated temperature environment. Convection heating is very versatile and not subject to bottom-side board geometry.

Construction of the DS Series system is based on a welded steel frame that has been carefully manufactured for high accuracy manufacturing. During assembly the system is subjected to a number of alignments and setups to ensure the highest level of precision. After manufacturing the systems will undergo the contour mapping process for the final touches on positioning capability.

All DS Series models are well suited for multi-functional applications combining dispensing with light assembly / pick & place applications.

A host of options are available to expand the capability of your system.

2 Work Area Sizes

- DS9000: 18" x 18" - The DS9000 model has a work area of 18" x 18" (457 mm x 457 mm), and is available in either an inline or stand-alone configuration.

- DS9100: 24" x 24" - The DS9100 model has the largest standard work area in the industry of 24" x 24" (610 mm x 610 mm), and is available in either an inline or stand-alone configuration

DS Series Standard Features:

- Large Format System

- Mounting for a Single Pump

- Computer Controlled Syringe Pressure

- Automatic Backlit Nozzle XYZ Calibration

- Automatic Nozzle Cleaning

- Automatic Digital Vision Alignment

- Contact Surface Sensing

- Red/Blue Illuminator

- Tool-less Taper-Lock™ Mounting Hardware

- FLOware® Operating Software with Smart Path Optimization

Add-On Options are available, please visit www,gpd-global.com or contact GPD Global +1(970)-245-0408 for details

Real Time Process Control - FPC

When dispensing fluids, there is always a question about the consistency of the fluid delivered to the pump. Different fluid materials, batches, and levels in the syringe or reservoir can affect the flow when fluid is fed from a syringe.

Fluid Pressure Control (FPC) is a breakthrough in uniform fluid dispensing. FPC ensures a constant supply of fluid is always available to the pump regardless of reservoir size or fluid level. FPC provides a consistent feed of fluid to the dispensing pump regardless of reservoir fluid level. FPC monitors the pressure of fluid entering the dispense pump and makes adjustments to the reservoir feed pressure, resulting in a consistent feed to the dispense pump

FPC is available in all GPD Global dispense platforms. An offline control system is available to interface with your existing dispense pump. Contact GPD Global +1(970)-245-0408 for details.

View Large / Versatile Board Processing - DS Series Dispenser

Large / Versatile Board Processing - DS Series Dispenser was added in Mar 2008

Large / Versatile Board Processing - DS Series Dispenser has been viewed 1805 times

15 More Products from GPD Global  :

: