ASYMTEK Products | Nordson Electronics Solutions

A leader in automated fluid dispensing, jetting, and conformal coating. Products include stand-alone dispensing workstations and fully automated, in-line conveyorized systems with advanced process controls.

Panorama S Line Inside Tour 2019

ASYMTEK Products have taken the lead for 35+ years to advance fluid dispensing, conformal coating, and jetting technologies. As part of the Nordson ELECTRONICS SOLUTIONS division, we focus on immediate and long-term possibilities, continuously innovating as technology and electronics applications evolve. By focusing on what’s possible, we bring more to our customers through innovative solutions, customization, applications expertise, and award-winning global support.

Recognized for our innovative equipment and excellent service, ASYMTEK continues to offer advanced dispensing solutions for a range of precision assembly processes. These include semiconductor packaging, printed circuit boards, LEDs, flat panel displays, medical and biotechnical devices, and solar and photovoltaic products. We are an ISO 9001:2015 certified company and has received numerous awards for its service excellence and product innovations.

ASYMTEK Products | Nordson Electronics Solutions Postings

Postings

22 products »

ASYMTEK Select Coat SL-1040 Conformal Coating System

With the Select Coat® SL-1040, we’ve retained the time-tested functionality of the Select Coat SL-940 and added significant system-level advancements to elevate automation, control, precision, and preventative maintenance for better yiel...

ASYMTEK SC-450 PreciseCoat Jet

Get more precision, process options, useability, yield, and uptime with the SC-450 PreciseCoat® conformal coating jet. The SC-450 PreciseCoat conformal coating jet widens the viscosity range to provide more process options. It's...

Qadence Flow Control for Conformal Coating

The ASYMTEK Qadence™ closed-loop flow control system maintains a stable flow rate by volume for high quality conformal coating results – automatically compensating for viscosity changes related to temperature, humidity and batch-to-bat...

The Forte™ Series delivers exceptional dispensing productivity and accuracy for high-volume consumer electronics manufacturing, printed circuit board assembly, flexible circuit, MEMs, and electromechanical assembly applications. Next...

Spectrum II S2-900 Series Fluid Dispensers

The world-class precision and quality Spectrum® II system for assembly of mobile electronics, semiconductors, MEMS, and PCBs High Speed, High Accuracy, Precision Dispensing System. Higher consistency leads to higher...

Quantum™ Q-6800 In-Line, Large-Format Fluid Dispensers

ASYMTEK Quantum Q-6800 High-Value Fluid Dispensing System. ASYMTEK Quantum Q-6800 Series. A high-value fluid dispensing solution for demanding applications. Large dispense area (423 x 458 mm) for varied substrate sizes...

Vantage - Advanced Dispensing for Precision Packaging and Assembly

Our most advanced dispensing platform for electronics manufacturing The Vantage® Series is specifically designed for high-end advanced semiconductor package, electromechanical, and printed circuit board assembly. Create...

IntelliJet Jetting System with ReadiSet Jet Cartridge

The IntelliJet® Jetting System with patented ReadiSet™ Jet Cartridge delivers cutting-edge reliability and micro dot dispensing for manufacturing advanced semiconductor and mobile electronics packages The piezo-driven...

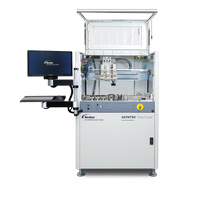

Panorama - Automated Conformal Coating Line Solutions

Nordson ASYMTEK designs automated conformal coating line solutions to fit your production process. Every Panorama™ line we build, includes the right balance of equipment and process control for optimal coating efficiency. If you&rs...

Select Coat SL-940 Conformal Coating System

The Select Coat® conformal coating machine provides the highest productivity and quality for your automated coating processes. Automate your conformal coating with state-of-the-art process controls, world-leading know-how, exp...

See all products from ASYMTEK Products | Nordson Electronics Solutions »

13 technical articles »

Case study: Precise Coating on Electronic Hearing Devices

Jun 20, 2024 | Nordson Electronics Solutions

A leading electronic hearing device manufacturer reduced UV precise coating cycle time by 79% with advanced automation. A manual process of hand brushing UV coating onto components was replaced by an automated solution from Nordson to increase production volumes, improve quality, and reduce costs for this complex application. Download the paper to learn the details of the application....

Dispensing EMI Shielding Materials: An Alternative to Sputtering

Jun 15, 2021 | Garrett Wong & Jinu Choi

Shielding electronic systems against electromagnetic interference (EMI) has become a hot topic. Technological advancements toward 5G standards, wireless charging of mobile electronics, in-package antenna integration, and system-in-package (SiP) adoption are driving the need to apply more effective EMI shielding and isolation to component packages and larger modules. For conformal shielding, EMI shielding materials for exterior package surfaces have mostly been applied with a physical vapor deposition (PVD) process of sputtering, leveraging front-end packaging technologies to back-end packaging applications. However, sputtering technology challenges in scalability and cost along with advancements in dispensable materials are driving considerations for alternative dispensing techniques for EMI shielding....

Dispensing EMI Shielding Materials: An Alternative to Sputtering

Feb 26, 2020 | Garrett Wong, Jinu Choi

Shielding electronic systems against electromagnetic interference (EMI) has become a hot topic. Technological advancements toward 5G standards, wireless charging of mobile electronics, in-package antenna integration, and system-inpackage (SiP) adoption are driving the need to apply more effective EMI shielding and isolation to component packages and larger modules. For conformal shielding, EMI shielding materials for exterior package surfaces have mostly been applied with a physical vapor deposition (PVD) process of sputtering, leveraging front-end packaging technologies to back-end packaging applications. However, sputtering technology challenges in scalability and cost along with advancements in dispensable materials are driving considerations for alternative dispensing techniques for EMI shielding....

Dec 07, 2017 | Camille Sybert, Michael Szuch

Electronics manufacturers protect their circuit boards with conformal coatings. Conformal coatings serve as a barrier from environmental hazards and internal shorts, tin whiskers, and corrosion at the board level. Within conformal coatings different material chemistries specialize in shielding from an array of hazards and can be applied by multiple methods. The most common method is atomized spray which disperses the material into a fine mist. Alternatively, non-atomized coating controls the materials' dispense shape while maintaining the original liquid form. While some applications demand atomized spray and other scenarios overlap between atomized and non-atomized coating, this paper focuses on the circumstances where materials are ideally suited for non-atomized, selective coating....

Making Sense of Accuracy, Repeatability and Specification for Automated Fluid Dispensing Systems

Nov 14, 2013 | Nordson Asymtek

Understanding accuracy and repeatability is an important step to analyze fluid dispensing system performance. They can also be prone to misinterpretation when reviewing a product specification. A dispensing motion system can be made to perform better or worse under different operating conditions. This article will explain accuracy and repeatability, and how they can be applied to different specifications. It will also discuss key considerations when interpreting accuracy and repeatability for decision making....

Conformal Coating Process Characterization Considerations

Sep 25, 2013 | Brad Perkins, Nordson ASYMTEK

Conformal coating is an enabling process that allows for the ruggedizing of electronic devices and modules. As the process increases the durability of electronics that are subjected to various end-use environmental conditions, it adds value to the product. While it does add value, consumers and manufacturers expect the electronics to work when subjected to dirt, humidity, moisture, corrosive materials, and various other contaminants. This expectation results in a drive to minimize the cost of the process. The lowest cost of ownership for a conformal coating process occurs by utilizing automated selective conformal coating equipment....

Throughput vs. Wet-Out Area Study for Package on Package (PoP) Underfill Dispensing

Dec 17, 2012 | Brad Perkins, Jared Wilburn

Package on Package (PoP) has become a relatively common component being used in mobile electronics as it allows for saving space in the board layout due to the 3D package layout. To insure device reliability through drop tests and thermal cycling as well as for protecting proprietary programming of the device either one or both interconnect layers are typically underfilled. When underfill is applied to a PoP, or any component for that matter, there is a requirement that the board layout is such that there is room for an underfill reservoir so that the underfill material does not come in contact with surrounding components. The preferred method to dispensing the underfill material is through a jetting process that minimizes the wet out area of the fluid reservoir compared to traditional needle dispensing. To further minimize the wet out area multiple passes are used so that the material required to underfill the component is not dispensed at once requiring a greater wet out area. Dispensing the underfill material in multiple passes is an effective way to reduce the wet out area and decrease the distance that surrounding components can be placed, however, this comes with a process compromise of additional processing time in the underfill dispenser. The purpose of this paper is to provide insight to the inverse relationship that exists between the wet out area of the underfill reservoir and the production time for the underfill process....

Advanced Solder Paste Dispensing

Oct 15, 2008 | Asymtek

Solder paste dispensing is usually considered a slow process. Due to the speed advantages, screen printing is used to apply solder paste whenever possible. However, screen printing is not always an option. Leveraging the high speed of piezo drive technology opens the door to a broad range of solder paste dispensing applications. The ability to dispense dots under 300-μm diameter, even as small as 125 μm, enables BGA rework, small geometry deposits for miniaturized passive components, electrical connections in recessed cavities, and RF shield attach for handheld devices....

An Alternative Dispense Process for Application of Catalyst Films on MEA's

Oct 01, 2008 | Horatio Quinones, Brian Sawatzky.

This paper proposes an integrated system for film application process than consists of closed loop mass calibration to assure film thickness, a noncontact fast jetting process with high edge definition capable of applying films for highly selective areas and patterns. A system to obtain homogeneity of the solid-fluid mix is described and results are shared....

Dam and Fill Encapsulation for Microelectronic Packages

Aug 27, 1999 | Steven J. Adamson and Christian Q. Ness

Contract packaging houses have to contend with a large mix of die types and products. Flexibility and quick turnaround of package types is a must in this industry. Traditional methods of die encapsulation, (i.e., use of transfer-molding techniques), are only cost effective when producing a large number of components. Liquid encapsulants now provide similar levels of reliability1, and are cost effective......

3 more technical articles from ASYMTEK Products | Nordson Electronics Solutions »

»

85 news releases »

![]() May 17, 2024 | The SL-1040 takes coating performance to the next level through improved yield and uptime with enhanced selectivity and flexibility for high-volume electronics manufacturing

May 17, 2024 | The SL-1040 takes coating performance to the next level through improved yield and uptime with enhanced selectivity and flexibility for high-volume electronics manufacturing

Nordson's semiconductor advanced packaging solutions will be demonstrated at SEMICON Taiwan 2023

![]() Aug 14, 2023 | See the Nordson Electronics Solutions equipment and talk to experts about the latest in fluid dispensing for semiconductor packaging at booth #L0800

Aug 14, 2023 | See the Nordson Electronics Solutions equipment and talk to experts about the latest in fluid dispensing for semiconductor packaging at booth #L0800

![]() Aug 26, 2022 | Conformal coating and fluid dispensing customers to benefit from SmartTec Nordic's years of experience in the region's electronics manufacturing industry

Aug 26, 2022 | Conformal coating and fluid dispensing customers to benefit from SmartTec Nordic's years of experience in the region's electronics manufacturing industry

![]() Sep 26, 2021 | Nordson TEST & INSPECTION division, part of the Nordson Corporation (Nasdaq: NDSN), are pleased to announce the launch of our X-ray Technologies OEM product range for industrial & pre-clinical X-ray imaging systems. This new product line is the result of several months of development work following the acquisition of vivaMOS, a leader in high resolution dynamic X-ray detectors.

Sep 26, 2021 | Nordson TEST & INSPECTION division, part of the Nordson Corporation (Nasdaq: NDSN), are pleased to announce the launch of our X-ray Technologies OEM product range for industrial & pre-clinical X-ray imaging systems. This new product line is the result of several months of development work following the acquisition of vivaMOS, a leader in high resolution dynamic X-ray detectors.

![]() Jun 30, 2021 | Increases process capacity for large PCB panels by more than 54% with only 2% increase in footprint

Jun 30, 2021 | Increases process capacity for large PCB panels by more than 54% with only 2% increase in footprint

Nordson Electronics Solutions Ships First SELECT Unit from New Global Manufacturing Facility

![]() Jun 23, 2021 | The relocation expands operations and capabilities for SELECT's selective soldering systems used in electronics manufacturing

Jun 23, 2021 | The relocation expands operations and capabilities for SELECT's selective soldering systems used in electronics manufacturing

![]() Apr 29, 2021 | ASYMTEK Forte™ MAX offers dual jetting with real-time skew correction for faster, enhanced, automated fluid dispensing

Apr 29, 2021 | ASYMTEK Forte™ MAX offers dual jetting with real-time skew correction for faster, enhanced, automated fluid dispensing

YESTECH Selected by Mexico Technology Awards for FX-942UV ACI / AOI

![]() Oct 29, 2020 | YESTECH Products, part of Nordson ELECTRONICS SOLUTIONS, received a 2020 Mexico Technology Award in the category of Conformal Coating for its FX-942UV ACI / AOI. The award was announced during a Virtual Awards Ceremony on Monday, October 26, 2020.

Oct 29, 2020 | YESTECH Products, part of Nordson ELECTRONICS SOLUTIONS, received a 2020 Mexico Technology Award in the category of Conformal Coating for its FX-942UV ACI / AOI. The award was announced during a Virtual Awards Ceremony on Monday, October 26, 2020.

![]() Oct 12, 2020 | Enables easier set-up and ensures accurate mix ratios by volume or weight to improve overall dispense quality

ASYMTEK, a part of Nordson ELECTRONICS SOLUTIONS - a global leader in electronics manufacturing technologies, announces its latest technology has received the Global Technology Award 2020 for fluid dispensing equipment. Nordson Electronics Solutions developed the patent-pending software, Automated Ratio Calibration Technology (ARC™ Technology), to enable easier set-up and sustained mix ratios for dispensing two-component (2K) fluid materials. ARC Technology is part of a system, which includes ASYMTEK Vortik® progressive cavity pumps and ASYMTEK dispensing platforms, that ensures consistently accurate mix ratios by volume or weight to improve overall dispense quality. The award was announced by Global SMT & Packaging magazine during a virtual ceremony held on September 29, 2020.

Oct 12, 2020 | Enables easier set-up and ensures accurate mix ratios by volume or weight to improve overall dispense quality

ASYMTEK, a part of Nordson ELECTRONICS SOLUTIONS - a global leader in electronics manufacturing technologies, announces its latest technology has received the Global Technology Award 2020 for fluid dispensing equipment. Nordson Electronics Solutions developed the patent-pending software, Automated Ratio Calibration Technology (ARC™ Technology), to enable easier set-up and sustained mix ratios for dispensing two-component (2K) fluid materials. ARC Technology is part of a system, which includes ASYMTEK Vortik® progressive cavity pumps and ASYMTEK dispensing platforms, that ensures consistently accurate mix ratios by volume or weight to improve overall dispense quality. The award was announced by Global SMT & Packaging magazine during a virtual ceremony held on September 29, 2020.

![]() Oct 10, 2020 | ASYMTEK, a part of Nordson ELECTRONICS SOLUTIONS announces its latest technology has received the Global Technology Award 2020 for fluid dispensing equipment. Nordson Electronics Solutions developed the patent-pending software, Automated Ratio Calibration Technology (ARC™ Technology), to enable easier set-up and sustained mix ratios for dispensing two-component (2K) fluid materials. ARC Technology is part of a system, which includes ASYMTEK Vortik® progressive cavity pumps and ASYMTEK dispensing platforms, that ensures consistently accurate mix ratios by volume or weight to improve overall dispense quality. The award was announced by Global SMT & Packaging magazine during a virtual ceremony held September 29, 2020.

Oct 10, 2020 | ASYMTEK, a part of Nordson ELECTRONICS SOLUTIONS announces its latest technology has received the Global Technology Award 2020 for fluid dispensing equipment. Nordson Electronics Solutions developed the patent-pending software, Automated Ratio Calibration Technology (ARC™ Technology), to enable easier set-up and sustained mix ratios for dispensing two-component (2K) fluid materials. ARC Technology is part of a system, which includes ASYMTEK Vortik® progressive cavity pumps and ASYMTEK dispensing platforms, that ensures consistently accurate mix ratios by volume or weight to improve overall dispense quality. The award was announced by Global SMT & Packaging magazine during a virtual ceremony held September 29, 2020.

75 more news releases from ASYMTEK Products | Nordson Electronics Solutions »

»