StencilMate™ Leadless Device Rework Stencils

Company Information:

Name: |

StencilMate™ Leadless Device Rework Stencils |

Category: |

|

Offered by: |

|

StencilMate™ Leadless Device Rework Stencils Description:

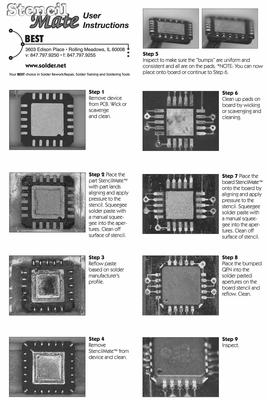

Simplify and Speed Up QFN and LGA device rework.

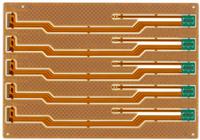

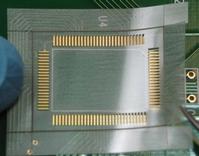

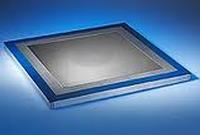

StencilMate™ leadless device rework stencils make the process of reworking leadless devices such as QFNs and LGAs simple and fast. These adhesive-backed poyimide stencils are placed on to the bottom of these device types. Solder paste is rolled in to the apertures. After reflow the stencil is removed, the device cleaned and now consistent, low voiding bumps are at the bottom of the device. This “bumped” part can now be placed just like a BGA or be fitted in to a matching stay in place stencil on the board.

This process greatly simplifies and speeds up the replacement process. If you are a technician trying to hand build a more complex PCB prototype board this is your answer as the requirement for more complicated and time consuming placement equipment is eliminated. Solder voiding is severely limited as the flux has lots of open air to let the outgassing of the volatiles to escape and not be entrapped. The standoff height is also increased so that cleaning media can get underneath to remove any soils left behind after reflow.

These are shipped in 3-5 days.

The simple nature of the StencilMate™ rework process makes it easy for you to reliably and quickly place or replace leadless device packages such as QFNs or LGA. The edges of the stencil are aligned with the sides of the package for alignement eliminating the need to use custom fixtures or frames. The adhesive has enough “tack” to hold the stencil in position once alignment of the stencil has been done. It does not have too much “tack” where if you misalign it is impossible to start over. After the device has been reflowed, the stencil is simply peeled off and the “bumped” device ready for placement.

Independent lab testing has confirmed (See Panel "B") that there are no harmful contaminants left behind as part of this process.

The StencilMate ™ stencils are custom made to your exact requirements using your part data sheet or Gerber file. There are NO tooling charges. They are shipped either 30 bumping or 10 mated bumping/board stencils to a pack in 3-5 days after drawing approval.

NOTE: IPC 7711/21 Procedure 5.8.1.1. and 5.8.1.2 are the StencilMate(TM) processes.

StencilMate™ Leadless Device Rework Stencils was added in Apr 2010

StencilMate™ Leadless Device Rework Stencils has been viewed 1700 times

20 More Products from BEST Inc. :