Nihon Superior Co., Ltd.

Nihon has been a leader in soldering and brazing since 1966. Nihon manufactures SMT solder joining materials e.g. lead-free solder (SN100C:Sn-Cu-Ni-Ge etc): solder paste, solder spheres, flux cored solder wire, solder bar, etc.

Nihon Superior was founded in 1966 when it began marketing unique flux products imported from the US. Since then, we have made our mark on society by gathering the most advanced soldering and brazing technologies and products from around the world, and supplying them to companies in the metal-joining industry.

Backed by our knowledge of these technologies, we have developed into a global company by establishing manufacturing and sales centers in Japan as well as in Asia and Europe, and by forming business partnerships with overseas companies.

We are committed to earning our customers' highest level of trust by taking full responsibility for every product we deliver to them, and we are ready to meet their rising demands for diversification, increasingly sophisticated technologies, and environmental protection. As always, we appreciate your ongoing support of our business endeavors.

The lead-free solder SN100C is an alloy of tin, copper, nickel and germanium. Its unique properties make it possible to achieve high productivity in soldering processes to produce cost effectively reliable joints. Special features include high fluidity, low copper erosion, low drossing, superior wetting and freedom from shrinkage defects. The number of companies using SN100C has grown dramatically since its first application in 1999 in the soldering of VCR boards.

Nihon Superior Co., Ltd. Postings

7 products »

TipSave N Flux-Cored Solder Wire

A new silver-free and lead-free solder alloy is now available from Nihon Superior. It reduces the wear rate of soldering tips. It is a new alloy developed to reduce soldering tip wear. It can achieve an improvement of about threefold compare...

We have a wide variety of flux-Cored solder, a mix of metal alloy, flux and other elements, that we have put together to match every type of application....

eFlux Lead-Free Soldering Flux

eFlux Selection: Rosin Based Flux for Lead-Free Wave Soldering NS-F850. NS-F850 ensures excellent wetting of all PCB and component substrates to deliver maximum...

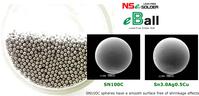

eBall Lead-Free Solder Spheres

High Reliability Lead-Free Solder Spheres SN100C. eBall Selection: Impact Strength SN100C (Sn-Cu-Ni+Ge)...

With its tin-copper-nickel-germanium alloy, SN100C is a popular lead-free wave soldering alloy. Although initially developed to address the need for an economical wave solder, it has since been found that its properties make SN100C ideal for re...

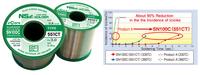

eCore Flux-Cored Lead-Free Solder Wire

In August 2007, Nihon Superior started simultaneous worldwide sales of SN100C (030) “eCore,” a resin flux cored, lead-free solder product, which contains the newly developed flux that enables the product to display the distinctive f...

A rich and line-up of solders possessed of various characteristics and properties. NSH63V forms a strong join and displays excellent resistance to heat cycle stress, thus prolonging the working life of various electrical devices....

5 technical articles »

Dissolution in Service of the Copper Substrate of Solder Joints

Jun 20, 2019 | Nihon Superior Co., Ltd, Department of Materials, Imperial College London

It is well known that during service the layer of Cu6Sn5 intermetallic at the interface between the solder and a Cu substrate grows but the usual concern has been that if this layer gets too thick it will be the brittleness of this intermetallic that will compromise the reliability of the joint, particularly in impact loading. There is another level of concern when the Cu-rich Cu3Sn phase starts to develop at the Cu6Sn5/Cu interface and an imbalance in the diffusion of atomic species, Sn and Cu, across that interface results in the formation at the Cu3Sn/Cu interface of Kirkendall voids, which can also compromise reliability in impact loading. However, when, as is the case in some microelectronics, the copper substrate is thin in relation to the volume of solder in the joint an overriding concern is that all of the Cu will be consumed by reaction with Sn to form these intermetallics.<p><p>This paper reports an investigation into the kinetics of the growth of the interfacial intermetallic, and the consequent reduction in the thickness of the Cu substrate in solder joints made with three alloys, Sn-3.0Ag-0.5Cu, Sn-0.7Cu-0.05Ni and Sn-1.5Bi-0.7Cu-0.05Ni....

Controlling Voiding Mechanisms in the Reflow Soldering Process

Nov 15, 2017 | Keith Sweatman, Takatoshi Nishimura, Kenichiro Sugimoto, Akira Kita

While a significant level of voiding can be tolerated in solder joints where electrical conductivity is the main requirement, voiding at any level severely compromises thermal conductivity. For example, in LED lighting modules effective conduction of heat through the 1st level die attach to the substrate and then through the 2nd level attach to the heat sink is critical to performance so that voiding in the solder joints at both levels must be minimized. (...) In this paper, the authors will review the factors that influence the incidence of voids in small and large area solder joints that simulate, respectively, the 1st and 2nd level joints in LED modules and discuss mitigation strategies appropriate to each level. They will also report the results of a study on the effect on the incidence of voids of flux medium formulation and the optimization of the thermal profile to ensure that most of the volatiles are released early in the reflow process....

Effect of Cooling Rate on the Intermetallic Layer in Solder Joints

Feb 28, 2013 | Keith Sweatman, Tetsuro Nishimura, Stuart D. McDonald, Kazuhiro Nogita

While it has long been known that the Cu6Sn5 intermetallic that plays a critical role in the reliability of solder joints made with tin-containing alloys on copper substrates exists in two different crystal forms over the temperature range to which electronics circuitry is exposed during assembly and service, it has only recently been recognized that the change from one form to the other has implications for solder joint reliability. (..) In this paper the authors report a study of the effect of cooling rates on Cu6Sn5 crystals. Cooling rates from 200°C ranged from 10°C/minute to 100°C/minute and the effect of isothermal ageing at intermediate temperatures was also studied. The extent of the phase transformation after each regime was determined using synchrotron X-ray diffraction. The findings have important implications for the manufacture of solder joints and their in-service performance... First published in the 2012 IPC APEX EXPO technical conference proceedings.......

Strength of Lead-free BGA Spheres in High Speed Loading

Apr 08, 2008 | Keith Sweatman, Shoichi Suenaga, Tetsuro Nishimura

Concern about the failure of lead-free BGA packages when portable devices such as cell phones are accidentally dropped and a general concern about the resistance of these packages under shock loading has prompted an interest in the impact strength of the soldered BGA connection. This paper reports the results of the measurement of the impact strength of lead-free 0.5±0.01mm diameter BGA spheres on 0.42mm solder mask defined pads on copper/OSP and ENIG substrates using recently developed equipment that can load individual BGA spheres at high strain rates in shear and tension....

High Reliability Lead-free Solder SN100C?Sn-0.7Cu-0.05Ni?Ge?

Mar 31, 2008 | Satoshi Mizuta

While the situation varies from country to country, nearly one year after the EU RoHS Directive came into force implementation of lead-free solder is progressing steadily. For lead-free soldering to be considered successful it is not sufficient just to have dealt with the challenges of mass production. It is also necessary to establish that the soldered joints produced are at least as reliable as those made with Sn-37Pb alloy. In this context "reliability" means the length of time in service that the initial functionality of the joint can be maintained. In this paper we will discuss some of the issues involved in solder joint reliability through a comparison of the properties of two alloys that are widely used for lead-free wave soldering, SAC305 (Sn-3.0Ag-0.5Cu) and the Sn, Cu, Ni, Ge alloy SN100C....

163 news releases »

Nihon Superior Sets New Standards in Lead-Free Soldering Technology at APEX 2024

![]() Mar 18, 2024 | Nihon Superior Co. Ltd., an advanced joining material supplier, will exhibit in Booth 1325 during the 2024 IPC APEX EXPO, scheduled to take place April 9-11, 2024 at the Anaheim Convention Center in California. Renowned for its commitment to innovation, Nihon Superior will present a range of groundbreaking products, including the SN100CV® P608 solder paste and the TempSave™ series of low-temperature soldering materials.

Mar 18, 2024 | Nihon Superior Co. Ltd., an advanced joining material supplier, will exhibit in Booth 1325 during the 2024 IPC APEX EXPO, scheduled to take place April 9-11, 2024 at the Anaheim Convention Center in California. Renowned for its commitment to innovation, Nihon Superior will present a range of groundbreaking products, including the SN100CV® P608 solder paste and the TempSave™ series of low-temperature soldering materials.

Nihon Superior's Keith Sweatman Wins a Coveted SMTA International Best Paper Award

![]() Nov 13, 2023 | Nihon Superior Co. Ltd. proudly announces that their Senior Technical Advisor, Keith Sweatman, has been honored with a coveted SMTA International Best Paper Award. This prestigious award was presented during the SMTA International 2023 Recognition Dinner, where Keith Sweatman was acknowledged as one of the four speakers who presented papers at the 2022 conference that were judged by their peers as the best in their respective categories.

Nov 13, 2023 | Nihon Superior Co. Ltd. proudly announces that their Senior Technical Advisor, Keith Sweatman, has been honored with a coveted SMTA International Best Paper Award. This prestigious award was presented during the SMTA International 2023 Recognition Dinner, where Keith Sweatman was acknowledged as one of the four speakers who presented papers at the 2022 conference that were judged by their peers as the best in their respective categories.

Nihon Superior and FCT Solder Extend Partnership with SN100CV License Agreement

![]() Nov 06, 2023 | Nihon Superior Co. Ltd. are delighted to announce the renewal of their longstanding partnership. In a testament to their shared success, Nihon Superior has granted FCT Solder a license for its innovative SN100CV solder alloy, reaffirming their commitment to collaboration. With this renewed partnership, FCT Solder has earned the distinction of being the first and exclusive licensee of Nihon Superior's SN100CV alloy in North America.

Nov 06, 2023 | Nihon Superior Co. Ltd. are delighted to announce the renewal of their longstanding partnership. In a testament to their shared success, Nihon Superior has granted FCT Solder a license for its innovative SN100CV solder alloy, reaffirming their commitment to collaboration. With this renewed partnership, FCT Solder has earned the distinction of being the first and exclusive licensee of Nihon Superior's SN100CV alloy in North America.

Nihon Superior's Mr. Keith Sweatman to Present at the 2023 SMTA International Technical Conference

![]() Oct 02, 2023 | Nihon Superior Co. Ltd. is pleased to announce that Keith Sweatman, the company's Senior Technical Advisor, will deliver a presentation titled "A Path to Ductile Low-Temperature Solders for Mass Production of Electronic Assemblies" at the upcoming SMTA International conference and exposition. This prestigious event is scheduled to take place Oct. 9-12, 2023 at the Minneapolis Convention Center in Minneapolis, MN. Keith Sweatman's presentation is scheduled within session LTS4, titled "Effects of Elemental Additions to Sn-Bi solder Alloys," and will take place on Thursday, Oct. 12, 2023, from 8:30 to 10:00 a.m.

Oct 02, 2023 | Nihon Superior Co. Ltd. is pleased to announce that Keith Sweatman, the company's Senior Technical Advisor, will deliver a presentation titled "A Path to Ductile Low-Temperature Solders for Mass Production of Electronic Assemblies" at the upcoming SMTA International conference and exposition. This prestigious event is scheduled to take place Oct. 9-12, 2023 at the Minneapolis Convention Center in Minneapolis, MN. Keith Sweatman's presentation is scheduled within session LTS4, titled "Effects of Elemental Additions to Sn-Bi solder Alloys," and will take place on Thursday, Oct. 12, 2023, from 8:30 to 10:00 a.m.

Nihon Superior to Highlight SN100CV P608 Paste at SMTAI

![]() Sep 11, 2023 | Nihon Superior Co. Ltd. is pleased to announce that it will exhibit its SN100CV P608 solder paste in Booth #1415 at the SMTA International Exposition, scheduled to take place Oct. 10-11, 2023 at the Minneapolis Convention Center in Minneapolis, MN.

Sep 11, 2023 | Nihon Superior Co. Ltd. is pleased to announce that it will exhibit its SN100CV P608 solder paste in Booth #1415 at the SMTA International Exposition, scheduled to take place Oct. 10-11, 2023 at the Minneapolis Convention Center in Minneapolis, MN.

Nihon Superior Launches Ag-free SAC305 Replacement – SN100CV

![]() Jan 09, 2023 | With its rule-breaking wave solder alloy, SN100C, Nihon Superior Co., Ltd. earned global recognition as an innovator in lead-free solder formulation. The rule that SN100C broke was that you can't make a Pb-free solder without a silver content that doubles the cost of the raw materials. Now Nihon Superior has broken that rule again with SN100CV, a reflow soldering alloy that can outperform SAC305 in reliability while being reflowable with the same thermal profile as SAC305.

Jan 09, 2023 | With its rule-breaking wave solder alloy, SN100C, Nihon Superior Co., Ltd. earned global recognition as an innovator in lead-free solder formulation. The rule that SN100C broke was that you can't make a Pb-free solder without a silver content that doubles the cost of the raw materials. Now Nihon Superior has broken that rule again with SN100CV, a reflow soldering alloy that can outperform SAC305 in reliability while being reflowable with the same thermal profile as SAC305.

Nihon Superior to Highlight TempSave Soldering Materials at IPC APEX

![]() Dec 21, 2022 | Nihon Superior Co. Ltd. is pleased to announce that it will exhibit its TempSave series in Booth #1433 at the IPC APEX Exposition, scheduled to take place Jan. 24-26, 2023 at the San Diego Convention Center in San Diego, CA. The company also will showcase LF-C2 P608 solder paste.

Dec 21, 2022 | Nihon Superior Co. Ltd. is pleased to announce that it will exhibit its TempSave series in Booth #1433 at the IPC APEX Exposition, scheduled to take place Jan. 24-26, 2023 at the San Diego Convention Center in San Diego, CA. The company also will showcase LF-C2 P608 solder paste.

Nihon Superior Introduces Lead-Free Solder Paste for Automotive Requirements

![]() Nov 15, 2022 | Nihon Superior Co. Ltd. is pleased to introduce its LF-C2 Lead-Free Solder Paste. Designed for automotive applications, LF-C2 is the high-strength alloy of choice when cracking minimization is a key selection criterion.

Nov 15, 2022 | Nihon Superior Co. Ltd. is pleased to introduce its LF-C2 Lead-Free Solder Paste. Designed for automotive applications, LF-C2 is the high-strength alloy of choice when cracking minimization is a key selection criterion.

Nihon Superior to Highlight TempSave Soldering Materials and SN100CV P608 Paste at SMTAI

![]() Oct 06, 2022 | Nihon Superior Co. Ltd. is pleased to announce that it will exhibit its TempSave series in Booth #1230 at the SMTA International Exposition, scheduled to take place Nov. 2-3, 2022 at the Minneapolis Convention Center in Minneapolis, MN. The company also will showcase SN100CV P608 solder paste.

Oct 06, 2022 | Nihon Superior Co. Ltd. is pleased to announce that it will exhibit its TempSave series in Booth #1230 at the SMTA International Exposition, scheduled to take place Nov. 2-3, 2022 at the Minneapolis Convention Center in Minneapolis, MN. The company also will showcase SN100CV P608 solder paste.

Nihon Superior to Highlight TempSave Soldering Materials at IPC APEX

![]() Jan 03, 2022 | Nihon Superior Co. Ltd. is pleased to announce that it will exhibit its newly developed TempSave series during the 2022 IPC APEX Virtual EXPO, scheduled to take place Jan. 25-27, 2022 at the San Diego Convention Center, San Diego, CA. The company also will showcase its TipSave N alloy along with SN100CV P608 and LF-C2 P608 solder pastes.

Jan 03, 2022 | Nihon Superior Co. Ltd. is pleased to announce that it will exhibit its newly developed TempSave series during the 2022 IPC APEX Virtual EXPO, scheduled to take place Jan. 25-27, 2022 at the San Diego Convention Center, San Diego, CA. The company also will showcase its TipSave N alloy along with SN100CV P608 and LF-C2 P608 solder pastes.