Austin American Technology

Austin American Technology engineers and manufactures high performance cleaning systems. Our systems include batch and inline; aqueous and solvent; spray in air and spray under immersion with ultrasonics.

AAT was founded in 1986, as a provider of hot gas rework systems and solder paste testing. In 1988, our focus shifted toward the high-end electronics cleaning segment with the introduction of the world's first automated stencil cleaner. In the 1990's, we developed several batch cleaning systems and were early adopters of closed-loop (zero-discharge) capability. During that period, we acquired the cleaning equipment division of ECD, offering batch systems that excelled in solvent and semi-aqueous-based cleaning.

In 2000, Austin American Technology became a market leader in inline cleaning systems with the introduction of the award-winning HYDROJET™ series. Patented cleaning and drying technologies were incorporated into an energy and space-efficient format to set new standards for performance and low cost of ownership. Building on this success, AAT introduced the MICROJET™ inline flip chip cleaner to provide high volume cleaning capability in a small footprint.

Austin American Technology Postings

7 products »

Aqueous / Semi-Aqueous Inline PCB Cleaning Systems Durable Construction The HydroJet™ in-line system is constructed of high-density polypropylene for excellent chemical compatibility and long life. It h...

There is nothing else like it! Designed, patented, and manufactured in the USA, the NanoJet™ from Austin American Technology combines recent advancements made in conveyor driven cleaning systems into the world's smallest, full...

World’s First Cleaner & ROSE Tester Removes Fluxes Performs IPC ROSE Test Closed Loop Operation - No Drains Aqueous or Organic Solvents Stainless Steel...

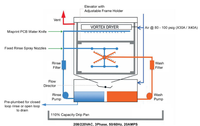

Aqueous and Semi-Aqueous PCB Cleaning Systems The MicroJet™ Inline cleaning System with Progressive Energy Dynamics™ provides the highest level of SMT cleaning available on the market today. Progressive...

PCB Stencil & Misprint Cleaning Systems Austin American Technology's X-Series™ Vertical Format Batch Cleaning Systems provide maximum chemistry flexibility to meet a wide variety of applications. Aqueous, sapon...

HydroJet™ SW - Solar Panel Cleaner

HydroJet™ SW Solar Aqueous / Semi-Aqueous Inline Electronic Cleaning Systems Breakthrough advances in cleaning technology bring Progressive Energy Dynamics to the HydroJet In-line Cleaning System resulting in unparalleled cle...

High Temperature, High Pressure Aqueous/Semi-Aqueous Batch Electronics Cleaning Systems Forget the limitations of the past and experience a batch system that offers multiple cleaning technologies for capability previously unachieve...

3 technical articles »

Sep 18, 2009 | Steve Stach, Austin American Corporation, Mike Bixenman, Kyzen Corporation

Electronic assembly cleaning processes are becoming increasingly more complex because of global environmental mandates and customer driven product performance requirements. Manufacturing strategies today require process equivalence. That is to say, if a product is made or modified in different locations or processes around the world, the result should be the same. If cleaning is a requirement, will existing electronic assembly cleaning processes meet the challenge? Innovative cleaning fluid and cleaning equipment designs provide improved functionality in both batch and continuous inline cleaning processes. The purpose of this designed experiment is to report optimized cleaning process parameters for removing lead-free flux residues on populated circuit assemblies using innovative cleaning fluid and batch cleaning equipment designs....

What Cannot Be Cleaned In a Stencil Cleaner

Sep 18, 2009 | Steve Stach, Austin American Technology

The stencil cleaner can be one of the most versatile tools on the manufacturing floor. It can be used to clean electronic modules in various stages of the manufacturing process. In fact, an automated stencil cleaner can clean just about anything you come up against in your PCB assembly process....

Jul 09, 2009 | Steve Stach.

Sometimes you just cannot clean with water. Good examples of this are: circuits with batteries attached, cleaning prior to encapsulation, ionic cleanliness testing, and non-sealed or other water sensitive parts. High impedance or high voltage circuits need to be cleaned of flux residues and other soils to maximize performance and reliability and, in these types of circuits; water can be just as detrimental as fluxes. When solvent cleaning is called for, Hansen solubility parameters can help target the best solvent or solvent blend to remove the residue of interest, and prevent degradation of the assembly being manufactured. In short, using this approach can time, manufacturing cost and reduce product liability....

47 news releases »

AAT Installs First Advanced X-40A 4.0 Stencil Cleaner at Jabil in San Jose

![]() May 27, 2024 | Austin American Technology (AAT) is pleased to announce the successful installation of its new X-40A 4.0 stencil cleaner at Jabil Inc. in San Jose. This installation marks the debut of the X-40A 4.0 version, featuring advanced I/O link devices and controls, simplified electrical composition, and smart notifications from components. These enhancements have been integrated into the most reliable and largest installed base fully automatic stencil cleaner on the market.

May 27, 2024 | Austin American Technology (AAT) is pleased to announce the successful installation of its new X-40A 4.0 stencil cleaner at Jabil Inc. in San Jose. This installation marks the debut of the X-40A 4.0 version, featuring advanced I/O link devices and controls, simplified electrical composition, and smart notifications from components. These enhancements have been integrated into the most reliable and largest installed base fully automatic stencil cleaner on the market.

![]() Mar 18, 2024 | Austin American Technology (AAT) and Aqua Klean Systems (AKS) are proud to announce the successful completion of their merger, creating the world's largest full-service electronics cleaning equipment manufacturer. The merger combines the strengths of both companies to provide an enhanced level of service to clients across various industries. AAT and AKS will be exhibiting together at Booth 4233 during the 2024 IPC APEX EXPO, scheduled to take place April 9-11, 2024 at the Anaheim Convention Center in California.

Mar 18, 2024 | Austin American Technology (AAT) and Aqua Klean Systems (AKS) are proud to announce the successful completion of their merger, creating the world's largest full-service electronics cleaning equipment manufacturer. The merger combines the strengths of both companies to provide an enhanced level of service to clients across various industries. AAT and AKS will be exhibiting together at Booth 4233 during the 2024 IPC APEX EXPO, scheduled to take place April 9-11, 2024 at the Anaheim Convention Center in California.

AAT's Patented Rotational Spraying Method Ensures Superior Cleaning Performance

![]() Mar 11, 2024 | Austin American Technology (AAT) is pleased to announce that its patented rotational spraying method ensures superior cleaning performance, delivering consistent results for critical electronic components. This revolutionary technique is integrated into the company's X Series Stencil Cleaner.

Mar 11, 2024 | Austin American Technology (AAT) is pleased to announce that its patented rotational spraying method ensures superior cleaning performance, delivering consistent results for critical electronic components. This revolutionary technique is integrated into the company's X Series Stencil Cleaner.

Todd Rountree Assumes the Role of CEO at Austin American Technology

![]() Feb 19, 2024 | Austin American Technology (AAT) proudly announces the appointment of Todd Rountree as Chief Executive Officer (CEO). With nearly 8 years of dedicated service as President and COO, Rountree brings a wealth of experience and a proven track record of leadership to his new role.

Feb 19, 2024 | Austin American Technology (AAT) proudly announces the appointment of Todd Rountree as Chief Executive Officer (CEO). With nearly 8 years of dedicated service as President and COO, Rountree brings a wealth of experience and a proven track record of leadership to his new role.

![]() Dec 18, 2023 | Austin American Technology (AAT) is pleased to announce special year-end pricing on its Aqua ROSE ES zero discharge batch cleaner. This limited-time offer presents an exclusive opportunity for businesses seeking cutting-edge cleaning technology at a reduced cost.

Dec 18, 2023 | Austin American Technology (AAT) is pleased to announce special year-end pricing on its Aqua ROSE ES zero discharge batch cleaner. This limited-time offer presents an exclusive opportunity for businesses seeking cutting-edge cleaning technology at a reduced cost.

![]() Oct 31, 2023 | Austin American Technology (AAT) is proud to announce that it has been honored with a prestigious Mexico Technology Award in the category of Cleaning Equipment. The award recognizes AAT's cutting-edge X-30 4.0 Fully Automatic Stencil, PCB & Misprint Cleaner for its outstanding innovation and performance. The announcement was made during a ceremony held on Wednesday, Oct. 25, 2023 at the SMTA Guadalajara in Mexico.

Oct 31, 2023 | Austin American Technology (AAT) is proud to announce that it has been honored with a prestigious Mexico Technology Award in the category of Cleaning Equipment. The award recognizes AAT's cutting-edge X-30 4.0 Fully Automatic Stencil, PCB & Misprint Cleaner for its outstanding innovation and performance. The announcement was made during a ceremony held on Wednesday, Oct. 25, 2023 at the SMTA Guadalajara in Mexico.

![]() Sep 25, 2023 | Austin American Technology (AAT) is proud to announce its pivotal role as a key sponsor for the on-camera interviews conducted by Justin Cody Worden for What's New in Electronics (WNIE) at SMTA International 2023, October 10-11 in Minneapolis, MN. In this exciting partnership, AAT underscores its commitment to supporting industry knowledge-sharing and fostering innovation within the electronics manufacturing sector.

Sep 25, 2023 | Austin American Technology (AAT) is proud to announce its pivotal role as a key sponsor for the on-camera interviews conducted by Justin Cody Worden for What's New in Electronics (WNIE) at SMTA International 2023, October 10-11 in Minneapolis, MN. In this exciting partnership, AAT underscores its commitment to supporting industry knowledge-sharing and fostering innovation within the electronics manufacturing sector.

Austin American Technology Creates Buzz with Justin Worden's 1st SMTA Presentation

![]() Sep 11, 2023 | Justin Worden, the dynamic Global Sales and Marketing Director at Austin American Technology (AAT), is no stranger to creating a buzz in the electronics industry. Known for his engaging presence on social media platforms, Worden and AAT have gained recognition for their unconventional marketing strategies. This reputation was once again validated at the recent Surface Mount Technology Association (SMTA) - High Reliability Cleaning and Conformal Coating Conference in Dallas, TX.

Sep 11, 2023 | Justin Worden, the dynamic Global Sales and Marketing Director at Austin American Technology (AAT), is no stranger to creating a buzz in the electronics industry. Known for his engaging presence on social media platforms, Worden and AAT have gained recognition for their unconventional marketing strategies. This reputation was once again validated at the recent Surface Mount Technology Association (SMTA) - High Reliability Cleaning and Conformal Coating Conference in Dallas, TX.

Austin American Technology Announces Merger with Aqua Klean Systems

![]() Feb 20, 2023 | Industry leaders in the Electronic Manufacturing field, Austin American Technology (AAT) and Aqua Klean Systems (AKS), are excited to announce a merger. As manufacturers of cleaning equipment, the former competitors have joined forces to become the world's largest and only full-service electronics cleaning equipment manufacturer. Both companies serve the automotive, medical, military and aerospace industries, and this merger is expected to further improve the high level of service clients have come to expect. Operation will continue at both facilities in Austin, TX and Anaheim, CA, while retaining all employees.

Feb 20, 2023 | Industry leaders in the Electronic Manufacturing field, Austin American Technology (AAT) and Aqua Klean Systems (AKS), are excited to announce a merger. As manufacturers of cleaning equipment, the former competitors have joined forces to become the world's largest and only full-service electronics cleaning equipment manufacturer. Both companies serve the automotive, medical, military and aerospace industries, and this merger is expected to further improve the high level of service clients have come to expect. Operation will continue at both facilities in Austin, TX and Anaheim, CA, while retaining all employees.

Austin American Technology Announces Top Sales Rep & Most Improved Territory for 2022

![]() Feb 06, 2023 | Austin American Technology (AAT) is pleased to announce that it recognized two of its manufacturers' representatives with awards during the 2023 IPC APEX EXPO at the San Diego Convention Center in California. Jim Rittman with Aligned Solutions was awarded 'Top Sales 2022' and Don Dennison with PIT Equipment Services was awarded 'Most Improved Territory'.

Feb 06, 2023 | Austin American Technology (AAT) is pleased to announce that it recognized two of its manufacturers' representatives with awards during the 2023 IPC APEX EXPO at the San Diego Convention Center in California. Jim Rittman with Aligned Solutions was awarded 'Top Sales 2022' and Don Dennison with PIT Equipment Services was awarded 'Most Improved Territory'.