Engineered Materials Systems, Inc.

A global manufacturer of adhesives, conductives and encapsulants. For over 20 years, EMS has formulated state of the art acrylics, epoxies, silicones and urethanes.

Engineered Materials Systems, Inc, is a global formulator and manufacturer of adhesives, conductives and encapsulants serving the appliance, automotive, filter, lighting, medical and microelectronics markets.

For over 20 years, EMS has formulated state of the art acrylics, epoxies, silicones and urethanes. EMS’s goal is to fill a void in the industrial market utilizing materials for assembly. EMS believes all applications are unique and specific. Our ability to define, develop and create solutions for our customers is superior when compared to our competitors.

EMS is a market leader providing innovative and cost effective solutions for original equipment manufacturers. Our customer commitment is another reason why EMS maintains market leadership in providing excellent engineered materials.

At EMS, we are committed to designing our customers specific adhesives that fit their application needs. Browse this site for information on how our formulations will fit your needs.

Engineered Materials Systems, Inc. Postings

1 technical article »

Durable Conductive Inks and SMD Attachment for Robust Printed Electronics

Oct 24, 2018 | Leonard Allison

Polymer Thick Film (PTF)-based printed electronics (aka Printed Electronics) has improved in durability over the last few decades and is now a proven alternative to copper circuitry in many applications once thought beyond the capability of PTF circuitry. This paper describes peak performance and areas for future improvement.

State-of-the-art PTF circuitry performance includes the ability to withstand sharp crease tests, 85C/85%RH damp heat 5VDC bias aging (silver migration), auto seat durability cycling, SMT mandrel flexing, and others. The IPC/SGIA subcommittee for Standards Tests development has adopted several ASTM test methods for PTF circuitry and is actively developing needed improvements or additions. These standards are described herein. Advantages of PTF circuitry over copper include: varied conductive material compositions, lower cost and lower environmental impact. Necessary improvements include: robust integration of chip and power, higher conductivity, and fine line multi-layer patterning....

78 news releases »

Engineered Material Systems Introduces Linear Resistance Carbon Inks

![]() Dec 04, 2019 | Engineered Material Systems, Inc. (EMS) is pleased to introduce CI-2069 Series carbon conductive inks for target resistance printing. CI-2069 Series inks feature excellent printability and stable resistance. The new ink series is offered in a suite of electrical resistance ranges.

Dec 04, 2019 | Engineered Material Systems, Inc. (EMS) is pleased to introduce CI-2069 Series carbon conductive inks for target resistance printing. CI-2069 Series inks feature excellent printability and stable resistance. The new ink series is offered in a suite of electrical resistance ranges.

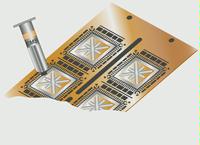

Engineered Material Systems Introduces Durable Printed Electronics with SMT

![]() Jun 15, 2019 | EMS introduces a revolutionary improvement in durability for printed electronics. EMS inks and adhesives have been designed for compatibility in chemistry and mechanical stress. The unique stack-up design channels paste placement for fillet strength and higher yield with smaller devices.

Jun 15, 2019 | EMS introduces a revolutionary improvement in durability for printed electronics. EMS inks and adhesives have been designed for compatibility in chemistry and mechanical stress. The unique stack-up design channels paste placement for fillet strength and higher yield with smaller devices.

![]() May 13, 2019 | Engineered Material Systems announces plans to exhibit at the SNEC PV Power Expo, scheduled to take place June 4-6, 2019 in Shanghai, China. The company will showcase its CA-150 Series snap cure, low cost conductive adhesive for stringing and shingling crystalline silicon and heterojunction solar modules in Hall W4, Booth 353.

May 13, 2019 | Engineered Material Systems announces plans to exhibit at the SNEC PV Power Expo, scheduled to take place June 4-6, 2019 in Shanghai, China. The company will showcase its CA-150 Series snap cure, low cost conductive adhesive for stringing and shingling crystalline silicon and heterojunction solar modules in Hall W4, Booth 353.

Engineered Material Systems to Showcase Electrically Conductive Adhesives at Intersolar Europe

![]() Apr 15, 2019 | Engineered Material Systems exhibit in Hall C1, booth 354 at the Intersolar Europa Solar Power Expo, scheduled to take place May 15-17, 2019 in Munich, Germany. Company representatives will show next-generation low-cost electrically conductive adhesives for stringing, shingling and back contact applications in crystalline silicon and heterojunction solar modules.

Apr 15, 2019 | Engineered Material Systems exhibit in Hall C1, booth 354 at the Intersolar Europa Solar Power Expo, scheduled to take place May 15-17, 2019 in Munich, Germany. Company representatives will show next-generation low-cost electrically conductive adhesives for stringing, shingling and back contact applications in crystalline silicon and heterojunction solar modules.

EMS Introduces Spin on Liquid Negative Photoresist NR-5000

![]() Feb 21, 2019 | Engineered Material Systemsis pleased to announce the availability of its NR-5000 series liquid negative photoresists for microfluidics and wafer level metallization processes. These material formulations have viscosities optimized for wafer coatings from 5 to 50 µm in thickness.

Feb 21, 2019 | Engineered Material Systemsis pleased to announce the availability of its NR-5000 series liquid negative photoresists for microfluidics and wafer level metallization processes. These material formulations have viscosities optimized for wafer coatings from 5 to 50 µm in thickness.

![]() Jan 15, 2019 | Engineered Material Systems is pleased to debut its TM-6520 low temperature cure adhesive. Designed for die attach and general circuit assembly applications, the adhesive is electrically insulating and offers high thermal conductivity.

Jan 15, 2019 | Engineered Material Systems is pleased to debut its TM-6520 low temperature cure adhesive. Designed for die attach and general circuit assembly applications, the adhesive is electrically insulating and offers high thermal conductivity.

EMS introduces 5 μm thick dry film negative photoresist DF-3505 for metallization processes

![]() Sep 27, 2018 | Engineered Material Systems, is pleased to introduce the availability of its DF-3505 series dry-film negative photoresists for wafer level metallization processes. This material formulation has been optimized for hot roll lamination and processing on MEMS and IC wafers.

Sep 27, 2018 | Engineered Material Systems, is pleased to introduce the availability of its DF-3505 series dry-film negative photoresists for wafer level metallization processes. This material formulation has been optimized for hot roll lamination and processing on MEMS and IC wafers.

![]() Sep 13, 2018 | Engineered Material Systems announces plans to exhibit at EU PVSEC, scheduled to take place Sept. 25-28, 2018 in Brussels, Belgium. The company will showcase next-generation low cost conductive adhesives for stringing, shingling and back contact applications in crystalline silicon and heterojunction solar modules in Booth D2.

Sep 13, 2018 | Engineered Material Systems announces plans to exhibit at EU PVSEC, scheduled to take place Sept. 25-28, 2018 in Brussels, Belgium. The company will showcase next-generation low cost conductive adhesives for stringing, shingling and back contact applications in crystalline silicon and heterojunction solar modules in Booth D2.

![]() Sep 05, 2018 | Engineered Material Systems debuts CA-188-1 low-temperature cure electrically conductive adhesive for die attach and general circuit assembly applications.

Sep 05, 2018 | Engineered Material Systems debuts CA-188-1 low-temperature cure electrically conductive adhesive for die attach and general circuit assembly applications.

![]() Jun 11, 2018 | Engineered Material Systems today announced that it will exhibit at the Intersolar Europa Solar Power Expo, scheduled to take place June 20-22, 2018 in Munich, Germany. The company will showcase its next-generation low cost conductive adhesives for stringing, shingling and back contact applications in crystalline silicon and heterojunction solar modules in Hall A2, booth 315.

Jun 11, 2018 | Engineered Material Systems today announced that it will exhibit at the Intersolar Europa Solar Power Expo, scheduled to take place June 20-22, 2018 in Munich, Germany. The company will showcase its next-generation low cost conductive adhesives for stringing, shingling and back contact applications in crystalline silicon and heterojunction solar modules in Hall A2, booth 315.

68 more news releases from Engineered Materials Systems, Inc. »

.gif)