Ersa ECOSELECT 1 Selective Soldering System

Company Information:

Name: |

Ersa ECOSELECT 1 Selective Soldering System |

Category: |

|

Offered by: |

|

Ersa ECOSELECT 1 Selective Soldering System Description:

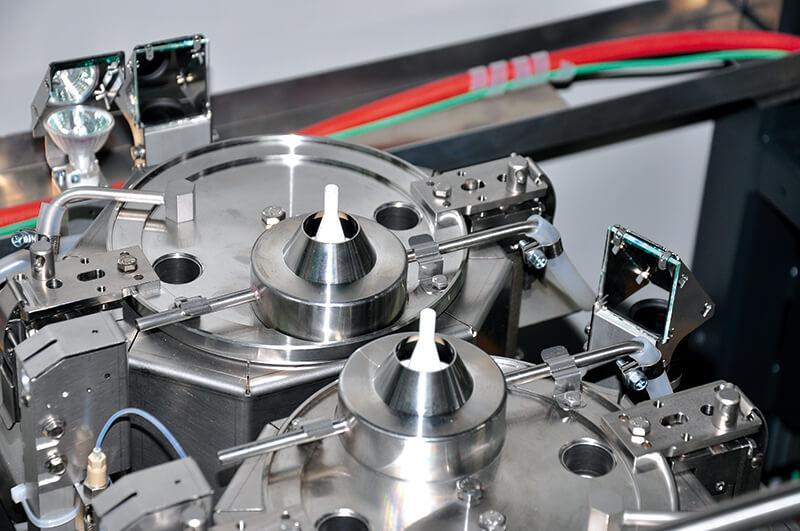

Ersa ECOSELECT 1 Selective Soldering System

- PCB:424 x 508 mm

- PCB weight: 8 kg

- Mini-wave 13 kg up to 2 pots

- Electromagnetic solder pot

- Product description: Ersa ECOSELECT 1 Selective Soldering System, PCB:424 x 508 mm, PCB weight: 8 kg, Mini-wave 13 kg up to 2 pots, Electromagnetic solder pot

Ersa ECOSELECT 1 Selective Soldering System

Specifications:

Compact Batch-type system with small footprint

Ersa CAD Software

Up to 2 solder bath to increase throughput

Use of mini-wave, mini-dip wave and area-soldering nozzle possible

Maintenance free electromagnetic solder pump drive

Drop-jet fluxer with integrated monitoring

High positioning accuracy and process safety

Lower, full-area IR preheater (scalable)

Convection top side

Low energy and N2 consumption

Selective Soldering System Ersa ECOSELECT 1

Optimal for manufacturing environments using cell production

With the ECOSELECT 1, Ersa expands its model range by a system which optimally fits, because of its small footprint of less than 3 m², into a manufacturing environment that is based on cell production. The semi-automatic ECESELECT 1 operates in all process steps with the proven Ersa selective soldering technology, just like the larger Ersa VERSAFLOW models, suffering no compromise in regards to quality and accuracy. The universal pallet mount allows processing boards with the size of up to 424 x 508 mm (optionally available 508 x 508 mm). The fluxer performs with the highest positioning accuracy and with the least amount of flux deposition.

Features such as spray jet monitoring, or the continuous pressure monitoring of the flux supply tank, ensure the presence of the proverbial Ersa process safety. Like the VERSAFLOW model range, the ECOSELECT 1 is equipped with a full area preheater cassette. The lower heater is furnished with 8 emitters, which can be switched in groups so that the power consumed can be adapted to the heat demand and the size of the board. The upper convection heater of the ECOSELECT 1 is optimally matched with the lower preheater, ensuring an effective and reproducible soak of even demanding board assemblies (multi-layer, heavy mass), with the energy being equally distributed across the complete board.

Innovative Dual Pot System

As are the large VERSAFLOW systems, the solder module of the ECOSELECT 1 comes also with electromagnetic pump installed, so that the bath is extremely low on maintenance. The pump ensures a very constant flow rate of solder and delivers therefore an exact and finely adjustable wave height. Dynamic process parameters such as solder level in the bath, solder wave height and solder temperature are continuously monitored and documented. With the innovative "peel off" feature, defects such as bridging when soldering at the 0° level are definitely no issue. The dual pot system allows that two different alloys are being used in the process. Extensive downtimes of the system due to pot change are thereby eliminated. Alternatively, the dual pot system can also be used for running the solder process with two different sized nozzles. The ECOSELECT is operated via PC controls with ERSAsoft. The process writer, which continuously records the actual values of all aggregates relevant to the soldering process, and the solder protocol, which stores the process data with all info required for traceability as per ZVEI standard, are part of the standard system specification.

Also a standard feature is the encompassing alarm management. All notifications are stored showing a time stamp and the user identification. All data is available in the XML format, and can therefore be easily worked on. With the help of the CAD assistant, DFX data of printed circuit boards can be used to create solder programs. As an alternative, picture of scanned-in boards can also be employed. All movements which the tables of the fluxer or the solder bath should be executing are graphically entered on the picture of the board, and followed by entering the process data. The program thus created can immediately be used on the ECOSELECT 1.

Dimensions

Length from 1,700 mm

Width approx. 1,500 mm

Height approx. 1,612 mm

Conveyour support

Universal pallet mount

PCB width: 15-406 mm (optional 508 mm)

PCB length: 15–508 mm

Maximum PCB top side clearance: 120 mm

Maximumg PCB bottom side clearance: 60 mm (30 mm upto z – variable)

Maximum PCB weight: 8 kg (option 12 kg)

Media supply

Nitrogen

Pneumatic system

Electric supply

Extracted air

Flux module

Drop-Jet in different sizes

Preheat module

IR heating, convection or combination of IR and convection

Solder module

Electromagnetic solder pot

Mini-wave 13 kg up to 2 pots

Keywords:

Samsung Nozzle yamaha Chip mounter Nozzle SMT Nozzle juki Nozzle Panasonic Nozzle pick and place machine Nozzle Seimens Nozzle, Universal Nozzle FUJI Nozzle sony nozzle Samsung Pick and Place Machine nozzle Hitachi Nozzle Hitachi Pick and Place Machine nozzle I Pulse Pick and Place Machine nozzle YAMAHA Pick and Place Machine nozzle

Flason Electronic Co, Ltd provide a full SMT Assembly Line solutions, including SMT reflow oven, Wave Soldering Machine, Pick and Place Machine, solder paste printer, PCB loader, PCB unloader, SMT AOI Machine, SMT SPI Machine, SMT X-Ray machine, SMT assembly line equipment, smt spare parts etc, any kind SMT machines you may need, please contact us by: wechat whatsapp:+86 13691605420,Skype: flasonsmt, Email: sales@smtkait.com

FAQ

1) This is the first time I use this kind of machine, is it easy to operate?

There is English manual or guide video that show you how to use machine.

If you still have any question, please contact us by e-mail / skype/ phone /trademanager online service.

2) If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.

If the part is less than 0.5KG, we pay the postage.

If it exceeds 0.5KG, you need to pay the postage.

3) MOQ ?

1 set machine, mixed order is also welcomed.

4) How can I buy this machine from you? ( Very easy and flexible !)

A. Consult us about this product on line or by e-mail.

B. Negotiate and confirm the final price , shipping , payment methods and other terms.

C. Send you the proforma invoice and confirm your order.

D. Make the payment according to the method put on proforma invoice.

E. We prepare for your order in terms of the proforma invoice after confirming your full payment.

And 100% quality check before shipping.

F.Send your order by air or by sea.

5)Why choose us ?

A. Gold supplier on Alibaba !

B. Trade assurance to US$100,000 !

C. Best price & Best shipping & Best service !

PREVIOUS:Siemens Siplace X4 Pick And Place MachineNEXT:Samsung SM310 Chip Mounter

RELATED PRODUCTS

PANASONIC MPA G3 Nozzle...

Panasonic 0201 01005 03015 Nozzle...

Panasonic KME CM88 Nozzle...

PANASONIC MPA NOZZLE...

CATEGORIES

SMT Reflow Oven

Wave Soldering Machine

Pick and Place Machine

SMT Stencil Printer

SMT PCB Inspection Machine

SMT Peripheral Equipment

SMT Assembly Line

SMT spare Parts

LATEST NEWS

SMT Defect List

WAVE SOLDERING DEFECTS 1

WAVE SOLDERING DEFECTS 2

SMT reflow oven typical trouble shooting

How to Prevent Solder Ball and Bridging Defects during the SMT Reflow Process

CONTACT US

Contact: Tommy

Phone: +86 13691605420

Tel: 0755-85225569

sales@smtkait.comAdd: No.94, Guangtian Road, Songgang Street, Bao`an District Shenzhen

When SMT matters to your business, partner with FLASON. Where innovation takes form. GuangDong ICP: 19148863 Sitemap

SMT Reflow Oven Wave Soldering Machine Pick and Place Machine SMT Stencil Printer SMT PCB Inspection Machine SMT Peripheral Equipment SMT Assembly Line SMT spare Parts SMT feeder SMT Nozzle reflow oven manufacturer SMT soldering machine SMT factory SMT feeder storage cart Andy: sales@smtkait.com Wechat/whatsapp:+86 13691605420

Ersa ECOSELECT 1 Selective Soldering System was added in Jun 2020

Ersa ECOSELECT 1 Selective Soldering System has been viewed 177 times

20 More Products from Flasonsmt Co.,ltd :