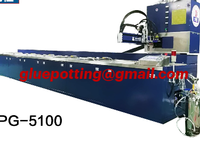

Automatic Ab Glue Dispenser for Electronic Part 2K Polyurethane Silicone Epoxy Ab Materials Automatic Mixing and Potting Machine

Company Information:

Name: |

Automatic Ab Glue Dispenser for Electronic Part 2K Polyurethane Silicone Epoxy Ab Materials Automatic Mixing and Potting Machine |

Category: |

|

Offered by: |

|

Automatic Ab Glue Dispenser for Electronic Part 2K Polyurethane Silicone Epoxy Ab Materials Automatic Mixing and Potting Machine Description:

Plug and Cable Potting

Even the tiniest gaps in plug housings, connectors and power supply units can be filled by potting masses. Potting materials for plugs and cables are flexible, highly water resistant, mechanically stable and tear-resistant. such as connector , switch potting

Photovoltaic Potting

Photovoltaic potting makes devices extremely weather-resistant, protects electrics against atmospheric fluctuations and the infiltration of damp, such as junction box potting, panel sealing and so on

LED Potting

Transparent or opaque potting systems protect LEDs from water, dust, and other atmospheric influences, enabling effective encapsulation as well as optimal light scattering for spotlight. Additionally, the Sonderhoff mixing and dosing system for LED potting avoids air bubbles and smears making optimal protection possible. such as led strip, wall washer, led driver, led display screen, other led lamps

Filter Potting This provides a leakage-free sealing of the frames and allows for the filtering of clean air. Foamed potting for bonding the filter medium into the filter frame enables cost and weight reductions, also meeting the high-quality requirements. Due to the foamed cell structure, the amount of adhesive per filter can be reduced by up to 50 percent. The lower density results in less weight that facilitates easier part handling. such as hepa filter, end cap filter , cabin fiter, air filter, ECO filter, oil filter potting and so on

| Sara Dong | |

| Sales Manager | |

| Email : gluepotting@gmail.com Whatsapp:+8613425164065 |

|

Automatic Ab Glue Dispenser for Electronic Part 2K Polyurethane Silicone Epoxy Ab Materials Automatic Mixing and Potting Machine was added in Oct 2023

Automatic Ab Glue Dispenser for Electronic Part 2K Polyurethane Silicone Epoxy Ab Materials Automatic Mixing and Potting Machine has been viewed 54 times

20 More Products from Guangzhou Daheng Automation Equipment Co.,LTD :

.jpg)