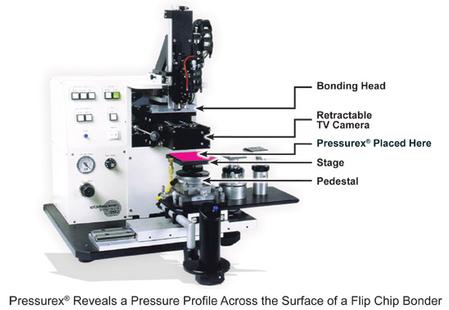

Pressurex® pressure-indicating sensor film provides a convenient, accurate, repeatable, and low cost control for both bonding and coplanarity. The thin flexible sensor film reveals pressures from 2 - 43,200 PSI (0.14 - 3,000 kg/cm2). When placed between the contacting surfaces of a flip chip bonder, it instantaneously and permanently changes color directly proportional to the amount of pressure applied. The precise pressure magnitude and distribution is then easily determined by comparing color variation results to a color correlation chart (conceptually similar to interpreting Litmus paper).

For further information and a complimentary sample of Pressurex® film in your desired range, contact Sensor Products Inc. at 1.973.884.1755 (USA), email info@sensorprod.com or visit http://www.sensorprod.com/sample. All products and applications can be viewed online.

About Sensor Products Inc.

Headquartered in New Jersey and established in 1990, Sensor Products Inc. is a world leader in the manufacture and distribution of tactile pressure sensing solutions. Their customized and off-the-shelf products are installed within all of the Fortune 500 industrial companies as well as thousands of smaller manufacturing firms. Their sensors are used in applications as diverse as tire testing to semiconductor manufacturing and from R&D labs to space missions. Additionally, Sensor Products provides in-house and on-site stress and pressure mapping analysis, as well as a variety of regional technical seminars.