A possible root cause for electronic device failure is an electrostatic discharge (ESD) event at the board level. Using anti-static labels can be an effective corrective action to help prevent static discharge events. POLYONICS’ TRIBOGARD® anti-static polyimide label materials, XF-781 and XF-782, were developed to address this issue.

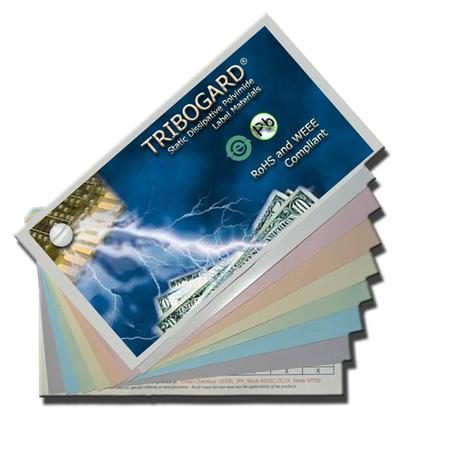

TRIBOGARD®, a new generation of barcode labels with enhanced anti-static technologies, is designed to withstand the harsh manufacturing processes of both standard and lead-free PCB production. For companies that have already implemented a label tracking system, switching the label from their current system to an anti-static system can increase production yields, product reliability and ultimately their profits.

POLYONCS’ TRIBOGARD® label materials are designed to address two major ESD concerns that standard labels can present. First, they eliminate the charge generated when the label is removed from the liner that can discharge and damage sensitive components during application. Second, after the label has been applied and during the label life, the TRIBOGARD® label prevents significant charge build-up on the label surface, which can result in a static discharge event.

POLYONICS provides label materials globally for many electronics manufacturers, built around its THERMOGARD® “harsh environment platform.” TRIBOGARD® not only enables real-time information for WIP tracking, but also provides anti-static features to protect boards and their components from ESD events during label application and label life.

Premiering in 2008, the NPI Awards program is an annual celebration of product excellence in electronics surface mount assembly. Premier products based on the finest examples of creative advancement in technology are chosen by a distinguished panel of industry experts.

hitech.gif)