New technologies such as package on package (PoP) component assembly or bare die assembly on COB applications, as well as the optimization of material consumption demands for increased knowledge of the actual placement forces. For this purpose Essemtec, a leading manufacturer of surface mount technology (SMT) production equipment, has developed a cost-efficient placing force measurement option for the FLX2011 series.

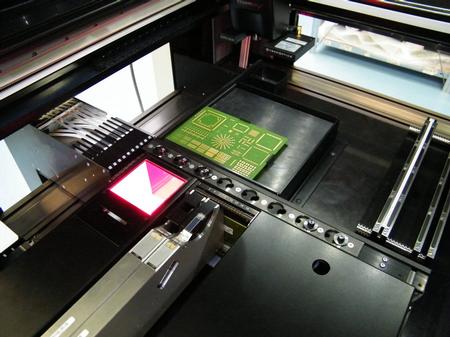

The measurement system consists of a chuck where the actual placement takes place. Substrates such as PCBs can be easily inserted and fixed. The chuck allows for the processing of substrates with a maximum size of 200x200x3 mm.

By means of a special software plug-in, the actual placement force from 0-5N ±0.5N can be predefined. Subsequently, the spring characteristic is calibrated for each nozzle and the data is stored in the database. The assistance of the track measurement ensures that the nozzle is processed in the correct force-path sequence for the component assembly. The force measurement begins as soon as the nozzle touches the substrate’s surface. Afterwards, the measured values are stored in a log file. The single force-path sequences of a placement process can then be analyzed and broken down to individual placement heads and nozzles, allowing for detailed analysis of the placement process.

The FLX2011 pick-and-place machine is state-of-the-art. It offers an extraordinary application range, ideal for subcontractors or product manufacturers producing a large variety of different PCBs. It features easy programming and setup, an intelligent feeder and inventory concept, and it enables changeover with no downtime. Two dosing systems can directly be integrated in the placement head. These features make the FLX2011 one of the most flexible machines available to the market.

The Swiss machine manufacturer Essemtec is a market leader in manufacturing flexible production systems for industrial users. Essemtec has been developing, manufacturing and marketing equipment and machines for all processes in the electronics industry since 1991: printers, dispensers, pick-and-place and soldering systems. Manual, semiautomatic and fully automatic systems are available. The range of products also includes transportation and storage systems, as well as software solutions for planning, simulation optimization and documentation of manufacturing. All Essemtec systems are optimized for maximum flexibility. Users can switch from one product to another quickly, making maximum use of available production capacity. Essemtec - Be more flexible.