Essemtec proudly introduces the Tarantula Dual Lane, our most advanced dispensing platform designed to redefine flexibility, speed, and scalability in modern electronics production.

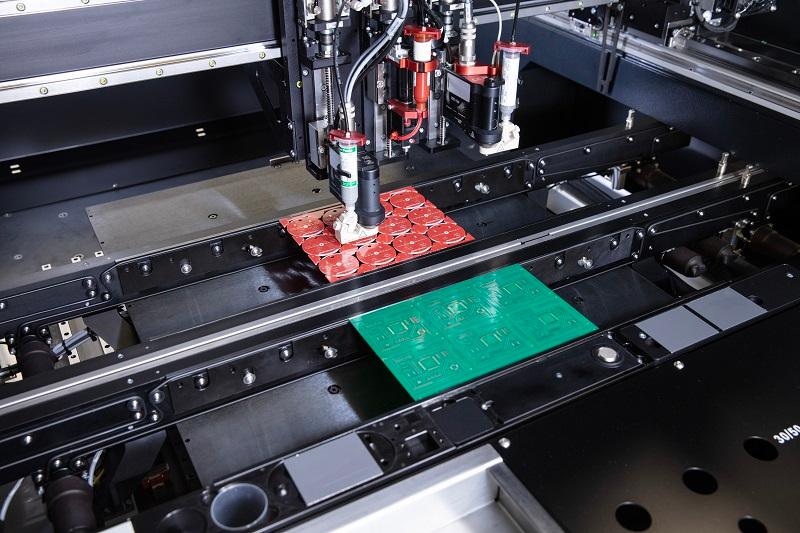

The new dual-lane architecture enables processing on two independent lanes. Built on Essemtec’s adaptive modular concept, the Tarantula Dual Lane supports up to three valve heads, making it the most versatile dispensing solution in its class.

With the ability to run up to 3 processes on a single platform, manufacturers benefit from simplified production lines, and a faster return on investment.

3 valves, 2 Lanes, 1 smarter Solution

Tarantula Dual Lane — Endless Versatility in Dispensing and Jetting

Performance Without Compromise

At the heart of the Tarantula Dual Lane lies Essemtec’s next-generation control and motion technology. With Jet-on-the-Fly, the system achieves up to 1.1 million dots per hour at maximum frequency, and an average of 350,000 dots per hour for complex boards in high-speed solder paste jetting.

For glue jetting applications, the Tarantula reaches a maximum frequency of 2 million dots per hour.

The platform supports up to three valves in parallel, offering full process flexibility—from solder paste to glue and epoxy jetting, thermal paste dispensing, or dam & fill applications. Whether used for fine-pitch solder paste deposits or staking, the Tarantula Dual Lane adapts precisely to your production requirements.

Versatility Without Limits

The Tarantula Dual Lane, along with other Essemtec dispensing platforms, is capable of jetting or dispensing almost any material used in modern electronic manufacturing and beyond.

Typical applications include dam & fill, 3D dispensing, jetting in cavities, staking, silver epoxy dispensing, shielding, microcoating, dielectric ink, liquid metal, thermal paste, and edge bonding.

The platform supports a wide board size range from 50 × 50 mm up to 560 × 500 mm, or identical board size up to 560 × 275 mm—offering true versatility for any production environment.

Quality, Precision, and Traceability

Combining both non-contact jetting and contact dispensing within a single system, the Tarantula Dual Lane ensures exceptional quality and consistency.

Optional 2D Solder Paste Inspection (SPI) with automatic correction enables continuous monitoring and optimization, while integrated traceability features guarantee complete control of materials and process parameters throughout production.

Efficiency Meets Sustainability

The Tarantula Dual Lane supports a more sustainable production model. By jetting only the exact amount of material required, it eliminates stencil cleaning chemicals and reduces material waste.

A single system performing multiple processes means fewer machines on the line—resulting in lower energy consumption, reduced floor space, and a smaller environmental footprint.

Ease of Use and Upgradability

Powered by Essemtec’s ePlace software and Optimizer tool, the Tarantula Dual Lane is intuitive, fast to set up, and easy to learn.

Its user-friendly ePlace interface enables operators to prepare a job in just minutes, and with the Gerber file import users can move from digital design to production in no time, as recipes can be automatically prepared for any new project, eliminating manual programming and setup delays.

As with all Essemtec systems, the Tarantula Dual Lane is fully upgradable—software updates, new valve technologies, and additional features can be added at any time, protecting your investment and ensuring long-term adaptability.

Now Also Available on the Puma Ultra Platform

The dual-lane concept is now also available for the Puma Ultra, Essemtec’s latest high-speed Pick-and-Place platform.

This expansion enables manufacturers to benefit from dual-lane productivity across both dispensing and assembly, unlocking new levels of efficiency for high-volume SMT production.

Compatibility with EasyLogix PCB-Investigator ensures a seamless transition from PCB design to production, unifying the process flow across Essemtec’s adaptive equipment ecosystem.

Experience It Live at Productronica 2025

Experience the Tarantula Dual Lane in action at Productronica 2025, Booth A3.261.

Join us to discover how Essemtec continues to push the boundaries of speed, precision, and sustainability in electronics manufacturing.