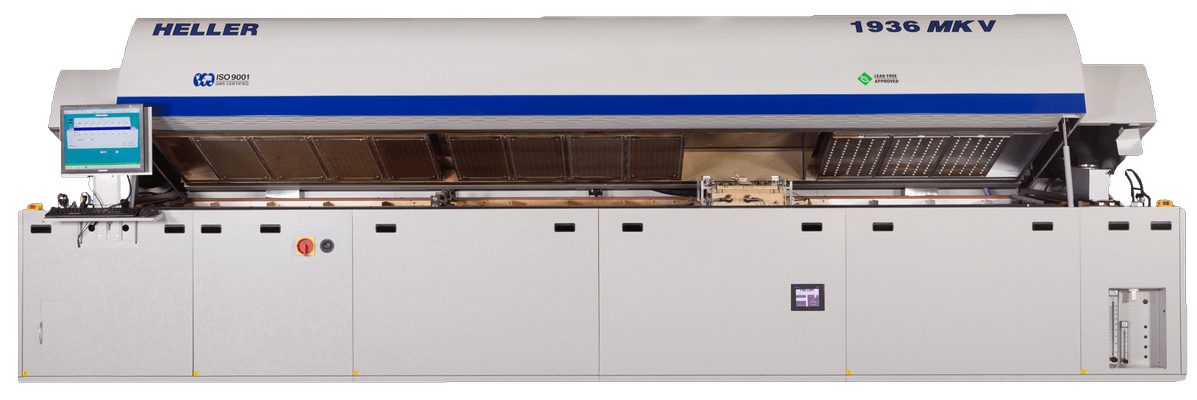

Altus Group emphasises the importance of reducing voids in reflow soldering to improve manufacturing efficiency and product reliability. As one of their key suppliers, Heller Industries, a global provider of electronic manufacturing reflow solutions, has developed multi-stage controlled vacuum technology that reduces void rates to below 1%. This technology is especially beneficial for industries like semiconductor and surface-mount technology (SMT) assembly, where maintaining high-quality solder joints is crucial.

With the increasing demand for high-performance electronics, reducing voids in solder joints is essential for ensuring long-term reliability. Heller’s vacuum-assisted reflow soldering process has proven to significantly reduce void rates by up to 99% while addressing substrate and wafer warpage, critical challenges for the electronics manufacturing industry.

Heller’s vacuum technology creates a controlled vacuum environment during the reflow process, allowing gas bubbles to escape, reducing void formation. This results in improved heat dissipation, better product stability, and enhanced performance, particularly in high-frequency applications. Additionally, the technology helps eliminate solder splatter and prevents solder bridging, further improving manufacturing efficiency.

Joe Booth, CEO of Altus Group, said: "We are lucky to have suppliers that are dedicated to developing solutions that make a real difference for our customers and voiding is top of mind for many globally. Heller's multi-stage controlled vacuum technology advancements are a perfect example of a supplier addressing a trend, offering manufacturers a way to improve solder joint quality and eliminate issues like voiding whilst mitigating warpage. By helping customers optimise their reflow soldering processes, we’re enabling them to achieve higher quality products and more efficient operations.”

Heller’s vacuum-assisted reflow technology, now widely implemented across customer installations in production, offers manufacturers a cost-effective solution with high efficiency and low unit per hour (UPH) rates, making it ideal for optimising production without compromising quality.

Altus in partnership with Heller are a significant force in the electronics manufacturing industry, helping manufacturers address key convection reflow process related challenges. Through its ongoing collaboration with Heller Industries, Altus is supporting over 200 manufacturing sites in the UK using Heller to improve process reliability, product quality, and operational efficiency, further reinforcing its role as a trusted industry partner.

www.altusgroup.co.uk.

Altus Group was formed in 2001 to support the UK and Irish market for Surface Mount Technology, capital equipment for every process, peripheral equipment, spares and consumables and most importantly excellent service support.

The Altus Group product line has evolved over the years with carefully selected suppliers who offer ‘best in class’ products at cost effective prices, from world leading brands.

The Altus Team has a network of highly skilled technical sales specialists, applications and service engineers, providing local support across the UK and Ireland.

In 2005 sister company Danutek was formed with offices in Hungary and Romania to service the needs of local customers and multi-national companies with manufacturing facilities in the Central and Eastern European marketplace.

www.altusgroup.co.uk