With its unique tin-copper-nickel-germanium alloy SN100C now firmly established as one of the global electronics industry�s most popular lead-free wave soldering alloys, Nihon Superior announces that it is extending the range of material forms in which the alloy is available.

Although developed initially to address the need for an economical wave solder, it has since been found that its properties also make SN100C an ideal choice for reflow and hand soldering as well as spheres for the attachment of area array packages.

The fluidity of SN100C, which is comparable to that of tin-lead, is one of the factors that contributes to excellent hole fill and minimal shorts in wave soldering. However, that property is also an advantage in hand soldering where, in combination with the right core flux (030) it makes possible the completion of more than 35 average joints per minute with a tip temperature of only 380�C. Nihon Superior is now offering the new eCore low-spatter lead-free flux-cored solder wire.

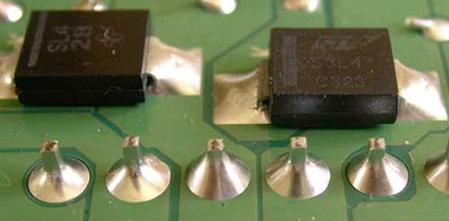

The 227�C melting point of SN100C was first thought to preclude its use in reflow soldering but when it was noted that tin-silver-copper alloys (such as SAC305 with a melting point of 217-218�C) are typically reflowed with a peak temperature around 245�C, it was realized that SN100C could be a drop-in replacement. Its high fluidity and excellent wetting properties mean that SN100C can be reflowed successfully at a lower superheat above liquidus than SAC alloys. Nihon Superior now offers two types of SN100C solder paste � no-clean ePaste for general reflow purposes and ePaste, a special low voiding paste for critical applications such as die attach in which heat transfer though the joint must be maximised.

Advantages of the tin-copper system include its ruggedness in impact loading and the nickel addition provides inhibition of the intermetallic growth that can increase the susceptibility of joints to failure in shock loading, e.g. when a mobile phone is dropped. These properties are prompting the industry to evaluate SN100C in flip chip and area array packages, and Nihon Superior is supporting this new application by making a range of eBalls available.

While a wide range of fluxes can used successfully in wave soldering with SN100C, Nihon Superior also is now offering eFlux, a new flux that has been specially formulated for optimum results.

Stop by Nihon Superior�s booth EAST6 59-18 at Internepcon Japan to find out more about the company�s new forms of SN100C soldering materials.

About Nihon Superior Co. Ltd.

Nihon Superior was founded in 1966 when it began marketing unique flux products imported from the US. The company made its mark on society by gathering the most advanced soldering and brazing technologies and products from around the world, and supplying them to companies in the metal-joining industry. A turning point for the company came when it started developing its own soldering materials and with the success of its unique SN100C lead-free solder alloy Nihon Superior has become a major player in the global market. To support the growing demand for its products Nihon Superior has established manufacturing and sales centers in Japan, China and other Asian countries and formed business partnerships with companies in other markets.