Nordson DAGE, Nordson MATRIX, and Nordson YESTECH, divisions of Nordson Corporation (NASDAQ: NDSN), will exhibit in Booth #1510 and 1511 at the 2017 IPC APEX EXPO, scheduled to take Feb. 14-16, 2017 at the San Diego Convention Center in California. Test and inspection solutions from Nordson DAGE, Nordson MATRIX and Nordson YESTECH will be demonstrated at the event.

Nordson DAGE’s flagship system – the new Quadra™ 7 with 0.1μm sub-micron feature recognition – comes equipped with two 4K UHD displays and 8 million pixels to fully show the 50μm pixel pitch and 6.7MP image size of the Aspire FP™ detector.

The Quadra™ 5, with industry-leading core technology, offers high performance and ease of use for 2D and 3D X-ray applications. 0.35μm feature recognition up to 10 W of power, makes the Quadra™ 5 the leading choice for printed circuit board and semiconductor package inspection.

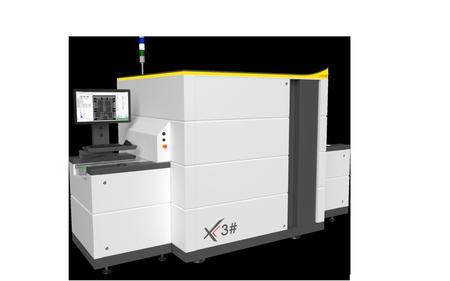

The Nordson MATRIX X3# is an automated inspection system designed for sophisticated high-speed inspection in SMT production. Transmission X-ray Technology with patented Slice-Filter-Technique™ (SFT), Off-Axis technology and 3D SART present a flexible solution package for the in-line inspection of single & double-sided PCB assemblies. The X3# movable detector axes allow high-speed off-axis image acquisition from different angles and directions with maximum image quality and resolution.

The Nordson YESTECH FX-940 ULTRA 3D AOI with cutting-edge 3D technology is ideal for the inspection of solder defects, lead defects/lifted leads, component presence and co-planarity of chips, BGAs and other height sensitive devices. With its Advanced Fusion Lighting and comprehensive inspection tools including angled cameras, full-color digital image processing and both image and rule-based algorithms, the FX-940 ULTRA offers complete inspection coverage with unsurpassed 2D and 3D defect detection.

Nordson DAGE, MATRIX and YESTECH, units of Nordson Corporation (NASDAQ: NDSN), manufacture and support a complete range of industry leading Test and Inspection products for the electronics industry. Offering an award winning portfolio of Automated Optical Inspection (AOI), Automated X-ray Inspection (AXI), Manual X-ray Inspection (MXI), Bond Testing, Micro Materials Testing and Wafer X-ray Metrology systems, Nordson’s family of Test and Inspection products bring powerful and cost effective solutions to the Printed Circuit Board Assembly (PCBA) and Semiconductor industries.

Nordson Corporation engineers, manufactures and markets differentiated products and systems used for the precision dispensing and processing of adhesives, coatings, polymers and plastics, sealants, biomaterials and other materials and for fluid management, test and inspection, UV curing and plasma surface treatment, all supported by application expertise and direct global sales and service. Nordson serves a wide variety of consumer non-durable, durable and technology end markets including packaging, nonwovens, electronics, medical, appliances, energy, transportation, construction, and general product assembly and finishing. Founded in 1954 and headquartered in Westlake, Ohio, the company has operations and support offices in more than 30 countries. Visit Nordson on the web at www.nordson.com, www.twitter.com/Nordson_Corp or www.facebook.com/nordson.