I.C.T has been working with suppliers to develop environmentally friendly lead-free solders and related materials and can now supply products that deliver high reliability. We also stand ready to work with customers in developing improved soldering materials and processes.Our objective is maximizing customer satisfaction by achieving the best possible quality and yield.

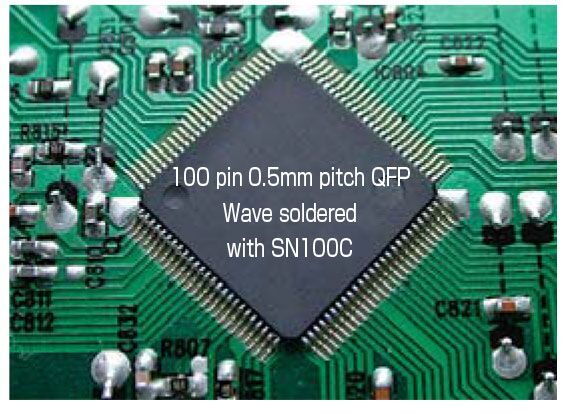

For Wave Soldering SN100C(Sn-Cu-Ni+Ge)

SN100C is being used in thousands of wave soldering machines around the world and has proved its reliability in products exposed to the most severe service environments.

Features

●The trace addition of Ni means fewer shorts and no shrinkage defects.

●Ni-stabilized intermetallic layer inhibits copper erosion.

●Reliable in harsh environments.

●High ductility ensure long service life of joints subjected to cyclic strain.

●SN100C is formulated for minimal generation of dross.

High Reliability Lead-Free Solder SN100C(Sn-Cu-Ni+Ge)

Features

● The fifinely dispersed microstructure of SN100C makes it possible to roll very thin foil without defects. The eutectic behavior of SN100C (Sn-0.7Cu-0.05Ni+Ge) lead-free preforms means good melting characteristics during reflow. The superior properties of SN100C with low intermetallic growth provide high reliability and flflexibility.

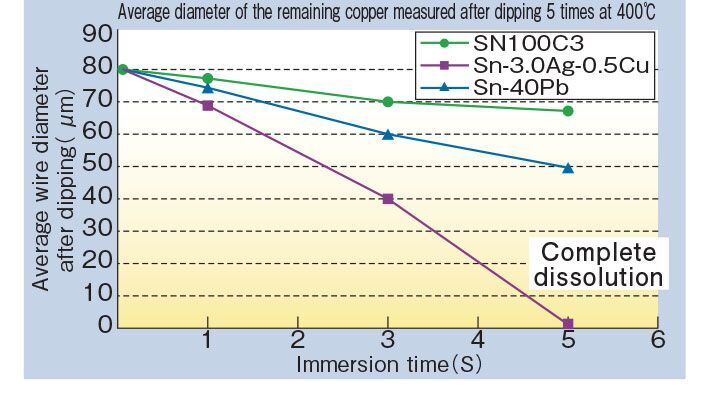

High Temperature Dipping and Tinning Solder SN100C3・SN100C4

Features

●SN100C3 and SN100C4 make it possible to carry out dip soldering and tinning operations with minimum copper erosion.

TOP Advantage:

Simple: combined with advanced international concepts, based on the Oriental-designed operating system, easy to learn, easy to maintain.

Expertise: learn imported reflow oven’s advanced design concepts, and the components are using imported top brands.

Hedging: Import hardware configuration,low failure rate in production,more than a decade service life.

Safety: Based on the general rules of international design, close to imported reflow rating, the highest security level.

Stable: mature software, hardware and top production processes ensures stability of each equipment.

Design Concept

Simplistic

Flexibility

Open Design

Modular Structure

Easy Maintenance

Tool-free Concept

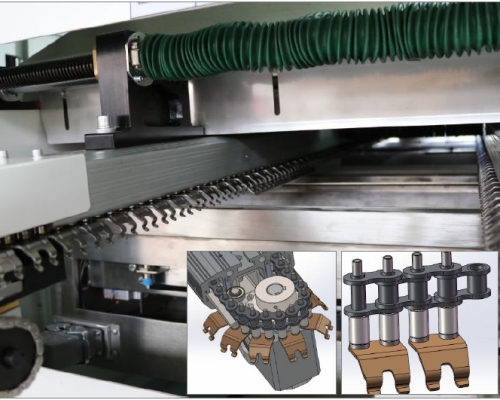

Conveyor System

Roller type double hook finger, force point increases roller sleeve,effectively reduce friction and wear.

Increase guide bracket and guide wheel, prevent chain knotting and clamping, and ensure transport stability.

Titanium finger no wetting and no deformation.

Full load > 60 kg.

Spray System

316 stainless steel material, corrosion resistance.

Sealing structure design to prevent flux pollution.

Tool-free plug-in filter with self-contained air extraction system.

Cover is opened manually,conducive to maintenance.

Selective spray optional.

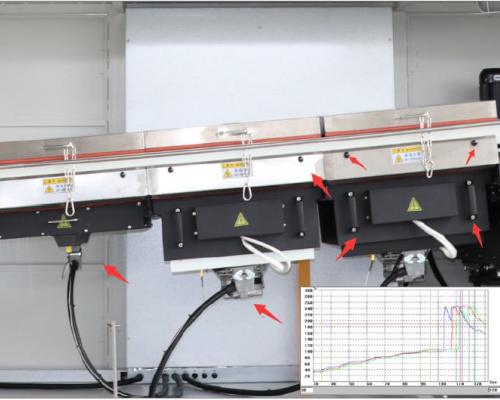

Preheating System

Efficient and stable heat conduction.

Design structure for maximizing preheating area.

All round high temperature cotton design to ensure temperature stability.

Heat-generating and heat-conducting parts and motors adopt top brands.

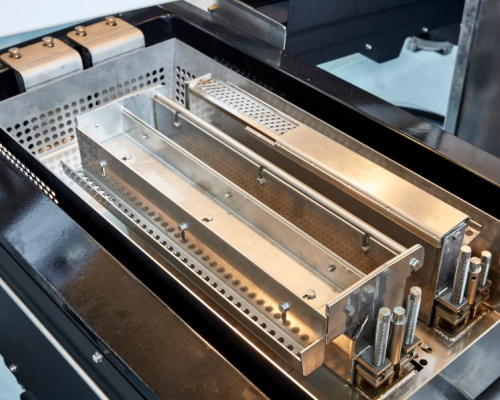

Soldering System

Steady solder flow channel design.

Wave peak stationarity less than 0.5mm.

Easy maintenance design structure.

Minimum oxidation of tin slag.

Wave peak Inverter Control.

Cooling System

Top and bottom convection modes.

High Power Cooling Fan.

Chiller is optional.

Control System

Humanized Operating Interface.

Standard circuit design, safe and reasonable.

Top brand for core parts

Specifications

AlloyProduct code

Melting point(℃)

SnAgCuNiGeOther

Sn-Cu-NiSN100CR-0.70.05≦0.01-227

SN100CL

R-0.7

0.05≦0.01-227

SN100C3R-3.00.05≦0.01-227-310

SN100C4R-4.0

0.05≦0.01-227-310

If you want to know more about our product, please contact us at: info@smt11.com

»

»