The Access Control Face Recognition system is a very widely used product. It is currently not only used in residential buildings and office buildings, but also in many scenarios.

For example, corporate attendance: Some companies also use the access control system to clock in and sign in to conference rooms.

On some campuses, dormitory management, school building access verification, examination verification, etc. will be carried out through the access control system.

In some industrial smart parks, they will use the access control system for visitor management, canteen payment, and so on.

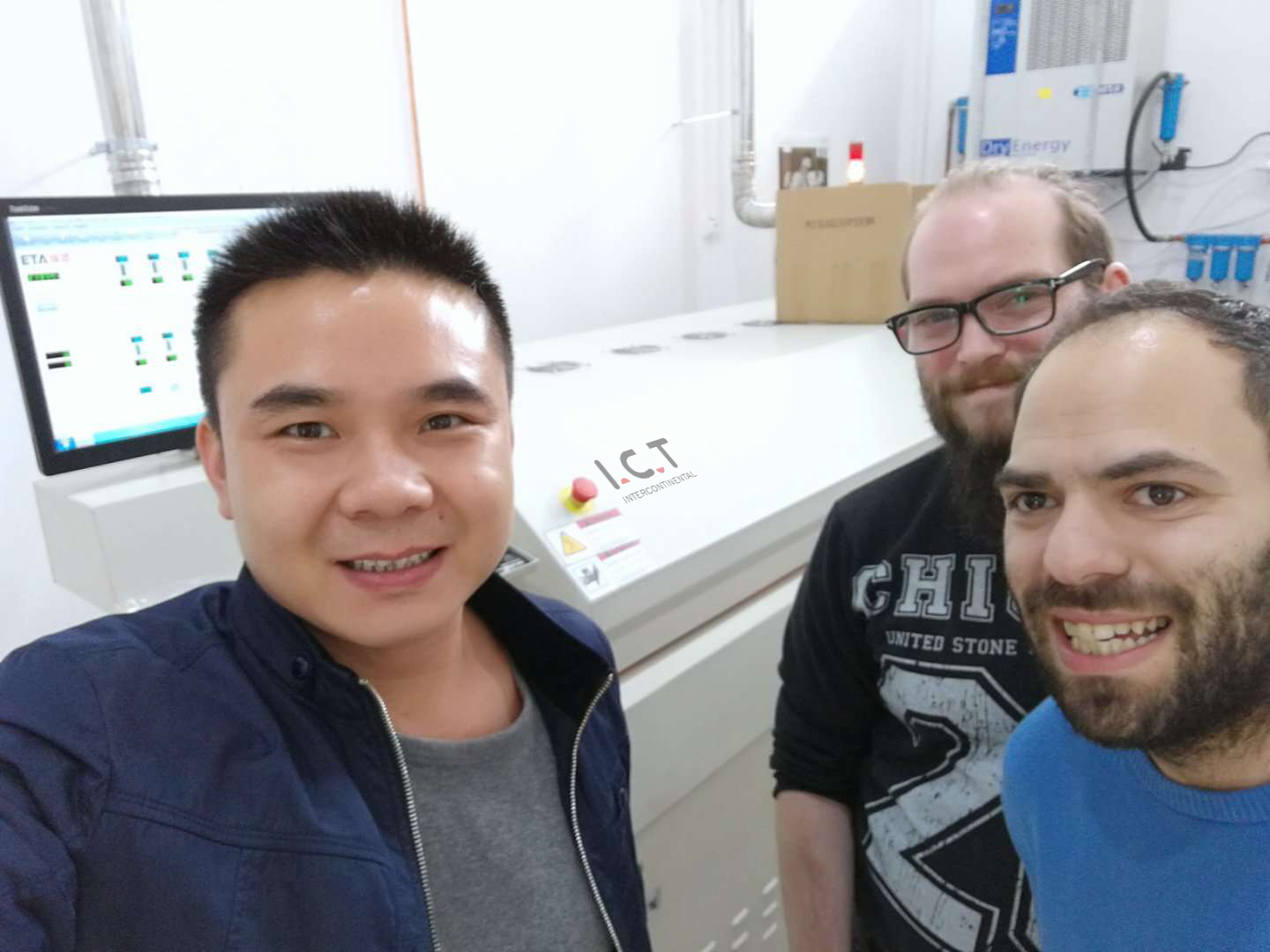

I.C.T Greek customers are doing face recognition systems for access control. Their company has only been in business for a few years. The production equipment they used before was desktop SMT production line equipment. With the increase in orders, they considered the need to upgrade their SMT Production Line.

Their SMT total production line will be still placed in the office, the space and budget are limited.

Our engineers provided customers with an SMT line solution using one Semi-Auto Stencil Printer P3, and two 0.5-Meter Conveyors, and one small Reflow Soldering Machine T8. These devices need to be placed separately because of the limited space.

I.C.T SMT Line in Greece

I.C.T SMT Machines in Greece

This production line requires 2-4 people to produce at the same time, working 10 hours a day, and the monthly output is roughly 500,000. This is a very big leap from the previous production capacity of 5,000 units per month. In the meantime, we provide customers with follow-up solutions:

The first is that we will provide customers with a mini PCB Loader, which is placed in front of the reflow soldering machine. After the SMEMA connection is made, he will regularly push the PCBA into the furnace for the reflow soldering machine. There will reduce the workload of one person.

Second, if they move to a larger production site in the future, and the semi-automatic SMT production line is upgraded to a fully automatic production line, the personnel cost will be directly reduced from 2-3 people to only one person, and the output will increase by another fifth.

Third, with the increase in production capacity in the future, testing equipment SPI and AOI machines also need to be added to the SMT production line to ensure product quality.

I.C.T SMT Oven in Greece

Reflow Oven

In January 2019, I.C.T engineer Peter went to Greece to do a week-long after-sales service for the customer. Debug each equipment and give training to customers, and use our equipment to produce the first batch of products. Customers also praised Engineer Peter.

»

» hitech.gif)

.gif)