Why Choose SMT Assembly?

-

Increased Efficiency

SMT assembly drastically reduces production time. High-speed placement machines can arrange over 50,000 components per hour, far surpassing manual assembly speeds.

-

Compact Design

SMT uses smaller components, allowing for greater component density and reduced product size and weight – crucial for today's consumer electronics.

-

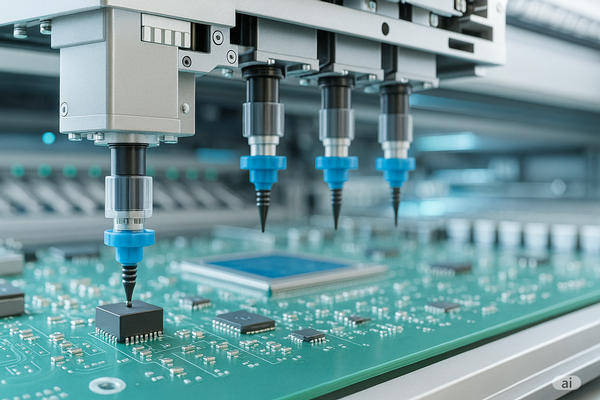

Automated Processes

With automated pick and place machines, SMT streamlines your processes, boosting productivity and minimizing manual errors.

-

Cost-Effective

Lower labor costs and faster production rates mean a higher return on investment, making SMT assembly a smart choice for long-term savings.

Implementing SMT Assembly: Key Steps

-

Assess Your Needs

Evaluate your current production setup to see if SMT assembly is a good fit. Consider volume, component types, and market demands.

- Invest in Quality Equipment

Choose reliable SMT assembly machines that offer precise placement and easy adjustments.

- Train Your Team

Ensure your staff is well-trained on the new equipment for safety and efficiency.

- Quality Control

Implement thorough inspections to prevent issues like misalignment or poor soldering.

- Continuous Improvement

Adopt Lean or Six Sigma to continually refine and optimize your processes.

Discover more: regulus-ems.com/post/smt-assembly

Ready to boost your production efficiency with advanced SMT assembly solutions?

Contact us to explore how we can support your project.

PCB Assembly Inquiry: regulus-ems.com/pcba-inquiry