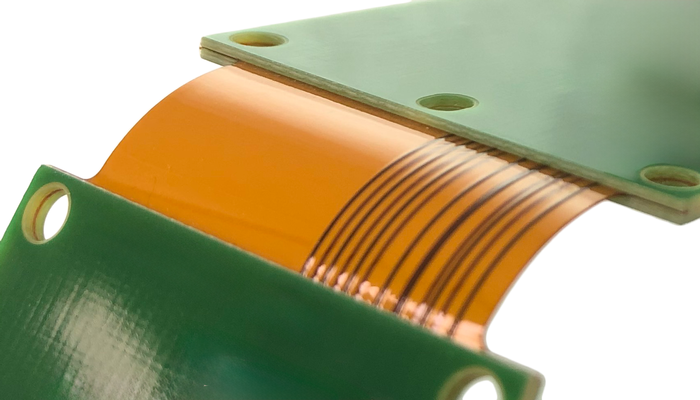

The Rise of Rigid-Flex PCB Solutions

Rigid-flex PCB solutions uniquely combine flexibility with structural integrity, gaining traction across radio communication, consumer electronics, navigation, industrial, fire & life safety and health & medical electronics industries. Unlike traditional PCBs, these integrate both rigid and flexible types into a single assembly, creating compact, lightweight, and highly reliable electronic devices. In consumer electronics such as smartphones and wearables, where space is at a premium, manufacturers can utilize rigid-flex PCBs to allow circuits to fold and bend without compromising electrical performance, leading to slimmer and more durable devices. These circuits have the capability to withstand harsh environments and mechanical stress, making them ideal for rugged applications, and enhance the reliability and compact form factors of safety products.

Advantages of Using Rigid-Flex PCB Solutions

- Space and Weight Reduction: Streamlined design by eliminating multiple connectors and cables.

- Improved Reliability: Fewer solder points reduce failure risks.

- Design Flexibility: Enables innovative 3D product designs.

- Enhanced Durability: Better endurance against vibration, shock, and thermal cycling.

- Simplified Assembly: Reduces assembly time and costs.

What is Rigid-Flex PCB?

Rigid-flex PCB combines rigid and flexible substrates into a single unit, supporting complex three-dimensional designs and reducing the need for multiple connectors and cables. The manufacturing process of Rigid-Flex PCB involves layering flexible circuits between rigid boards, connected through plated through-holes, which are conductive holes that create reliable electrical connections between layers. Regulus offers comprehensive rigid-flex PCB manufacturing services , supporting industries such as industrial electronics and health & medical electronics. Their expertise ensures high-quality production, from component sourcing to final testing, enabling faster product development and optimized supply chains.

Practical Applications of Rigid-Flex PCB Solutions

- Consumer Electronics: Smartphones, tablets, and wearables.

- Radio Communication: Portable radios and communication devices.

- Navigation and Tracking: GPS devices and sports electronics.

- Industrial Electronics: Machinery and control systems.

- Fire & Life Safety: Smoke detectors and emergency systems.

- Health & Medical Electronics: Diagnostic equipment and wearable health monitors.

How Regulus Supports Your Rigid-Flex PCB Needs

Partner with Regulus, a trusted Electronics Manufacturing Services (EMS) provider, to accelerate product development and ensure high-quality outcomes. We specialize in turnkey PCB assembly services and complete box build assembly solutions.

Embracing the Future of Electronics Design

Rigid-flex PCB solutions represent a paradigm shift in electronic device design and manufacturing, opening possibilities for innovation, miniaturization, and durability. Partner with experienced EMS providers like Regulus to bring your designs to life efficiently with the highest quality standards.

Unlock the full potential of rigid-flex PCB assembly with Regulus. As a professional Taiwan-based PCBA manufacturer, we deliver complete PCB assembly solutions, from SMT and THT to full box build assembly services, ensuring speed, quality, and scalability. Contact us today for a custom solution.