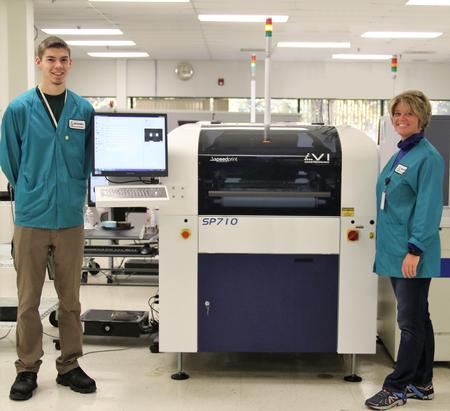

New Hampshire-based Contract Manufacturer, Cirtronics, has taken delivery of its fifth screen printer from Speedprint Technologies. The company is renowned for its smart investment strategy in the finest assembly equipment for its manufacturing facility in Milford, NH, to serve customers across the US.

Like the other Speedprint printers on the Cirtronics production floor, the latest SP710 printer is equipped with Speedprint’s unique, dual-head ADu+ dispensing system, built right into the printer. Cirtronics was among the first Speedprint customers to recognise the distinct advantages in flexibility and productivity offered by the ability to dispense extra solder paste or adhesive at the screen print stage of assembly.

“There’s no doubt that Cirtronics makes great use of the ADu+ facility in our printers,” says Mark Brawley, President of Speedprint. “The print quality from these advanced platforms is a given. But dispensing adds an extra dimension by allowing the company’s manufacturing engineers to remain agile with their assembly process. For instance, they can add extra paste when required and respond rapidly to changes, for example to accommodate customer board changes or product variants at short notice without creating a new stencil.”

VP of Manufacturing at Cirtronics, Jim McCall, points out that his Engineering and Quality teams are constantly evaluating the investment required for every new product entering the production floor. “We are committed to manufacturing high-quality products and need to make strategic investments that support our customers’ success,” he says. “The fifth Speedprint printer increases our production capacity and was an easy decision. We have been delighted with the ease of use and reliability of these robust print platforms. Features like in-printer dispensing add to the flexibility we enjoy, allowing us to confidently address any customer subassembly.”

Cirtronics is an established and trusted brand in the US Contract Manufacturing sector. The company specialises in modern manufacturing services which it tailors to address the specific needs of each customer. Cirtronics manufactures sophisticated products for a broad range of demanding, quality-sensitive markets including communications, defense, robotics, medical technology, and industrial applications.

Cirtronics is a US contract manufacturer based in the Boston, Massachusetts area specializing in electronics, electro-mechanical assemblies and box builds for a wide range of quality-sensitive markets including medtech, robotics, communications, aerospace, military, security and industrial applications. Cirtronics is an Employee Owned Company (ESOP) that qualifies for US government woman-owned and small business status, is FDA and ITAR Registered, and ISO 9001 and 13485 Certified. To learn more about Cirtronics and how they use Precision Engagement® to tailor their services to the needs of each customer, visit www.cirtronics.com.

The Blakell Europlacer Group comprises the Speedprint Technology, Europlacer, and Blakell Europlacer Distribution business units. All three are active and pre-eminent in the electronic circuit board assembly sector with advanced product and service solutions for electronics manufacturers in the UK, US and globally. Speedprint Technologies is a provider of screen printing equipment used in surface mount assembly processes. Europlacer is a provider of surface mount component placement equipment. Blakell Europlacer Distribution augments the provision of screen printing and pick & place platforms in the UK with a range of associated equipment, including AOI, reflow and PCB handling.