MARTIN will showcase its Mini-Oven Reball/Prebump unit and Expert 10.6 rework system in Booth #407 at the upcoming SMTA International Conference & Exhibition, scheduled to take place October 18-19, 2011 at the Fort Worth Convention Center in Fort Worth, TX.

MARTIN’s Mini-Oven 04 Reball/Prebump unit is ideal for the complete QFN solder bumping process, even for the smallest pitches. Using a unique Hotprint Technology, the mask is not removed after printing paste, but remains on the QFN during reflow.

The reballing function is capable of handling a diverse range of BGAs, as well as QFNs and CSPs. Processes can be completed in as little as three minutes. The simple Rapid Technology soldering profiles rigorously apply settings within the permitted thermal limits, heat at the highest advisable thermal ramp rates and maintain a safe temperature zone.

The unit offers programmable modes and a nitrogen process gas supply. Up to 99 profiles can be accommodated, with the ability to edit individual profiles and fine tune parameters.

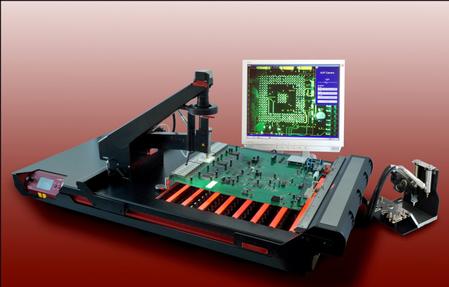

Also at the show, MARTIN will demonstrate the Expert 10.6, a cost-effective rework system with an intuitive interface, process repeatability and semi-automated operation. A leading-edge camera driven alignment system provides a flawless solution for the automatic placement process. The hybrid platform combines both infrared and convection heating technologies to achieve outstanding board temperature uniformity, thus minimizing temperature-based PCB distortion.

MARTIN has developed affordable rework, BGA reballing, hand soldering, and dispensing technologies for nearly 30 years. The USA sales and service office is located in Manchester, NH. The company‘s manufacturing facility is in Wesseling, Germany. MARTIN is a FINETECH company.