Cogiscan, a leading track, trace and control solutions provider for the electronics manufacturing industry, has received a major order from ACD, a leading supplier to the electronics industry. ACD invested in a factory-wide Track, Trace and Control (TTC) Solution for all material, including printed circuit boards (PCBs), electronic components, tooling (feeders, stencils) and consumables (solder paste, etc.) from receiving to shipping.

The Cogiscan TTC Solution will replace ACD’s incumbent MES software. Cogiscan was selected to replace the legacy system due to its proven track record to deliver on its commitments. The Cogiscan software architecture is very open for seamless integration with existing systems. This enables ACD to handle simple integration projects with internal development resources.

“I am thrilled about this new project. ACD is a strong leader in the EMS industry and it has a clear understanding of the value that Material TTC software can bring to its business and customers. This will be an outstanding showcase for Cogiscan because ACD will deploy the complete suite of Cogiscan TTC applications,” commented François Monette, Co-President Sales and Marketing, Cogiscan.

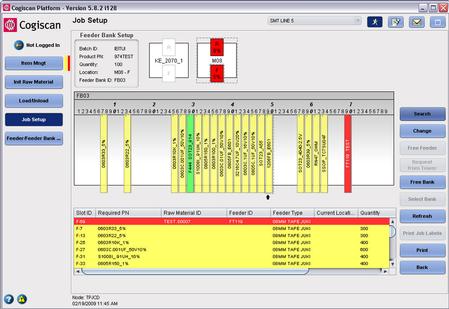

Prior to this new purchase, ACD had been using a subset of the Cogiscan TTC Solution for almost a year since the purchase of its new Juki lines with the IFS-X2 intelligent feeder system. When the company learned that IFS-X2 could be expanded to the rest of the factory, ACD contacted Cogiscan to investigate further. As the local manufacturers’ representative for Juki and Cogiscan, Southwest Systems Technology, Inc. was closely involved in the order.

“Cogiscan’s pre-sale work on this project along with its reputation in the marketplace made it a clear choice as a complete end-to-end upgrade to replace our current MES system,” commented W. Scott Fillebrown, President & CEO of ACD.

“The IFS-X2 system developed jointly by Juki and Cogiscan is widely recognized as the best solution on the market for setup validation and component traceability,” added Monette. “An important and unique aspect of IFS-X2 is that customers can tie it with other brands and models of SMT machines, and integrate all their lines with a central ERP/MRP system. They also can expand the basic IFS-X2 system to cover any other material management requirement across the entire factory, from receiving to shipping. This is exactly what ACD will be doing in its state-of-the-art facility. We look forward to a long and successful collaboration with ACD.”

Founded in 1984, ACD’s services comprise complete board layout services, ATE engineering services, DFM/DFA capability, printed circuit fabrication, component procurement, SMT and thru-hole mixed technology assembly, box build, rework, X-Ray, flying probe and functional test, and development.

Cogiscan is the leader in material control for the electronics manufacturing industry. The company offers Real-time tracking, traceability, and control of all materials (feeders, components, PCBs, solder paste) throughout SMT and other assembly processes. Cogiscan provides cost-effective and scalable solutions that ensure the right material is in the right place at the right time.