KIC will debut the Reflow Process Index (RPI) in Booth #2428 at the upcoming IPC APEX Expo, scheduled to take place February 28-March 1, 2012 at the San Diego Convention Center in California.

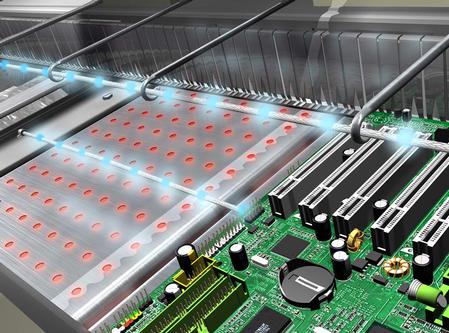

The KIC RPI helps manage reflow ovens to consistently maximize the desired results. In addition, the RPI provides process deficiency information in order to help users correct their defect issues quickly. The RPI is an automatic system that, once programmed, works in the background without any operator involvement. Its capabilities include:

- Provides process deficiency information to help correct defect issues quickly

- Shares all pertinent process and production data in real-time

- Automatically profiles each and every PCB

- Provides instant alarm for out-of-spec situations

- Automatic SPC charting, including Cpk

- Process traceability down to individual PCBs

- Prevents human error such as production of the wrong PCBs or wrong oven recipe settings (bar code required)

The KIC RPI improves quality and throughput, and is universally applicable because it is independent of the oven model, production lines, personnel, PCB types, and even factory.

Also on display, the KIC 24/7 Wave utilizes embedded sensors in the wave solder machine to automatically measure the thermal profile for each and every processed PCB to the acceptable process window. A thermocouple also is installed in the solder pot to constantly measure the pot temperature.

Any out of spec situation is immediately identified, while the standard SPC charts automatically provide Cpk numbers with the ability to provide alarms when the process starts drifting. Every PCB profile is recorded for easy retrieval for full process traceability. Traceability down to the individual PCB is achieved when bar codes are used.

The initial programming of the KIC 24/7 Wave is performed with a KIC profiler. The KIC profiler is capable of quickly identifying the appropriate wave solder settings for an improved process.

For more information about KIC’s new Wave 24/7 or KIC RPI, visit KIC in Booth #2428 at the show or on the Web at www.kicthermal.com.

Based in San Diego, KIC is the industry leader in automated thermal management tools and systems for reflow, wave, cure and semiconductor thermal processes. The company pioneered the development of oven profilers and process optimization tools, and then worked to create the next generation of thermal systems to help manufacturers improve the thermal process quality while reducing cost.

In addition to KIC Explorer, products include the KIC RPI reflow process inspection system, the KIC Vision automatic profiling system and more. With the introduction of cutting edge tools, the company continues to stay on the leading edge of process optimization and automatic thermal management systems, and has won numerous industry awards.

hitech.gif)