LPKF Laser & Electronics, a leading manufacturer of laser and electronics systems, announces that it will highlight its laser plastic welding systems in Booth #3786 at the upcoming International Plastics Showcase, scheduled to take place April 1-5, 2012 at the Orange County Convention Center in Orlando, Florida.

Although there are many traditional methods for welding plastic parts, LPKF’s laser plastic welding systems demonstrate clear advantages with higher control and joining quality, less stress to the component and the ability to weld complex and intricate shapes. Primarily found in the automotive, medical and consumer electronics industries, laser plastic welding systems produce a wide variety of applications including small plastic sensor housings, tail lights, highly complex microfluidic devices and balloon catheters.

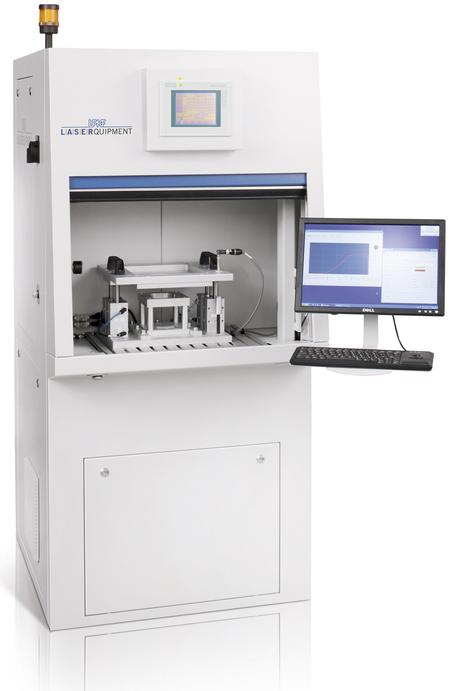

The LPKF laser plastic welding family is comprised of three primary systems: The LQ Vario, LQ Power and TwinWeld3D. With nearly unlimited customization and options, these machines can be fitted to suit the needs of the most demanding plastic welding projects.

For more information about these machines, meet company representatives in Booth #3786 at NPE 2012 or visit www.lpkfusa.com.

LPKF Laser & Electronics is the world leading manufacturer of both mechanical and laser systems for demanding tasks in printed circuit board technology and microelectronics. LPKF’s worldwide headquarters is located in Garbsen, Germany outside of Hannover and the company maintains North American headquarters in Portland, OR.