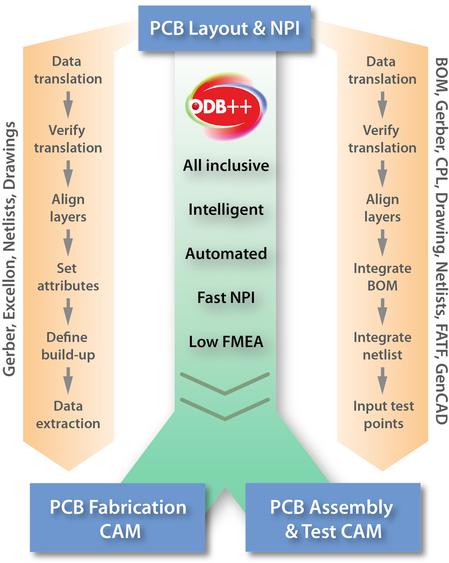

The ODB++ Solutions Alliance has been established today to provide an open forum for implementers and developers of the ODB++ format, an intelligent, single-data structure for transferring printed circuit board (PCB) designs into fabrication, assembly and test. Introduced in 1995 by Valor Computerized Systems, ODB++ was the industry’s first open format for unified data exchange globally between PCB design and manufacturing companies. The proven and available ODB++ format provides a better design-to-manufacturing methodology to communicate and share data across disciplines, as a replacement to a traditional range of lower-level files such as Gerber, Excellon, netlist, placement list, and drawings.

The ODB++ Solutions Alliance is comprised of both users and solutions-development partners to facilitate the successful implementation of the ODB++ format, offering access to free software tools, specifications, documentation and continuous improvement to the format and implementation methodologies. The ODB++ Solutions Alliance launch partners include companies involved in the design-through-manufacturing ecosystem: Assembléon, Cadence, Downstream, Easylogix, Frontline, Mentor Graphics, Nagoya Electric Works, Optimum Design, Orbotech, Streamline Circuits, Viasystems Group, Wise Software and Zuken. With this open, vendor-neutral alliance, the ODB++ format will continue to be driven, as before, by the thousands of its users worldwide. Thus, Alliance members will provide a focal point for further technological development and adoption of the data format. Membership and access to the Alliance resources are free.

“With full utilization of intelligent ODB++ files, we can greatly reduce the amount of manual time-consuming human interaction and the opportunity for quality errors,” stated Kent Balius, vice president of global front-end engineering, Viasystems Group, Inc., a leading worldwide provider of complex multi-layer printed circuit boards and a partner of the ODB++ Solutions Alliance. "This saves Viasystems time, money and enables faster response to the customer, helping to ensure on-time delivery of a high-quality end product."

ODB++ intelligent data delivers a manufacturable design requiring minimal preparation effort at the fabricator or assembly house, thus reducing cycle time and significantly improving new product introduction (NPI) quality. Using the integrated ODB++ format, manufacturers will have a complete set of data defining the PCB product model for manufacturing: drill, inner-, outerand component-layers, net data, and bill-of-materials. The ODB++ format also provides a wide range of capabilities that make separate drawings unnecessary since the format is a single selfcontained structure. Conversely, Gerber data requires manual inspection of data followed by “reverse-engineering” to the manufacturing-oriented model of the product to be fabricated and assembled. The Gerber approach is cumbersome, requiring time to manually import, analyze, prepare and cross-check data for accuracy, with an average of 25% of data packages getting held up due to data anomalies.

"The self-contained single file structure of the ODB++ format delivers a low-risk, high-quality data set that makes the PCB fabrication and assembly NPI processes virtually error-free, while at the same time saving valuable time and cost,” stated Julian Coates, director of business development for the Valor® division of Mentor Graphics. "Members of the Alliance realize the importance of ODB++ as an established open format used globally. We intend to broaden its adoption by sharing best practices via the Alliance and online technical resources made freely available to members. All stakeholders in the PCB design-through-manufacturing world are welcome to join."

For more information on the ODB++ Solutions Alliance, a list of its partners, and how to join, visit the website: www.odb-sa.com. During the IPC-APEX EXPO 2012, please visit the Mentor Graphics® booth #1435 for further information on the Alliance.

The ODB++ Solutions Alliance provides a forum for implementers and supporters of the ODB++ format to share their interest and success with others. Alliance members can exchange information, advice and ideas about the format, including implementation of best practices and their experiences in using the format across the PCB design-through-manufacturing flow. The overall goals of the ODB++ Solutions Alliance are to increase awareness of what is being achieved today with ODB++ in reducing time-to-market, cost and supply-chain risk, and provide the basis for wider adoption by designers and manufacturers so as to maximize the benefits for the PCB engineering community, and further enhancement of the format and its implementation methods in line with technological developments. Website: www.odb-sa.com.