Seratel have announced extended reporting capabilities for their "Reel aMounts" component counting and labelling system, bringing the system to smart phones and tablets.

The Reel aMounts system provides unprecedented speed and flexibility in reel counting, allowing users to count and label tape and reel material in seconds. The operator controls the system using a bar code scanner and no manual input is required during normal component counting.

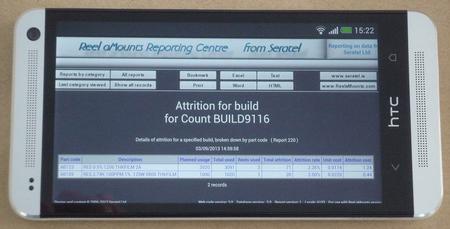

Despite its ease of use, Reel aMounts collects a substantial amount of information without any further input from the operator. For every reel counted, the system creates a database record, holding not just the part code and new quantity on the reel, but over twenty other items of information. It logs the operator, date and time. It saves a unique reel ID, assigned when the reel was first labelled, and what work order the reel was last used for. It also includes in the database the quantity of components used and will use BOM and work order details to calculate any attrition.

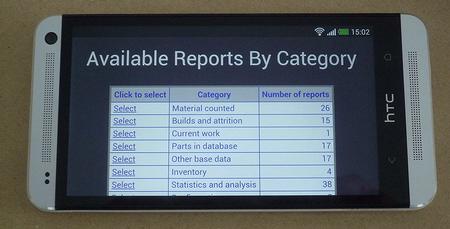

All this data provides a valuable resource for costing and allowing for attrition, batch traceability - even locating "missing" material. To provide easy access to the information, Reel aMounts is supplied with Reel aMounts Reporting Centre - a web based tool that can be deployed on any PC within a company. Reporting Centre provides over 150 reports in 10 categories. These range from top-level analysis down to individual reel traceability and component inventories detailed by reel.

Seratel are now extending support of Reporting Centre to both smart phones and tablets. Seratel's Michael Bloor says, "Reporting Centre was first created seven years ago, in response to customer demands for an easy and open way to view the data collected by Reel aMounts. Those people now expect to be able to access corporate data from anywhere, and not just on PCs. Support for Reporting Centre on mobile devices provides that ability."

Reel aMounts provides high speed counting for all tape and reel components, by linking a computer, electronic weighing scales, bar code scanner, bar code printer and a database of component types. The system allows companies to maintain accurate inventories, taking into account all attrition, including handling losses.

It uses patented Reel MagicTM technology to match the parameters of each reel against an inbuilt database of reel and component types, derived from measurements of thousands of SMT components. This allows it to tune its counting algorithms to make the best possible adjustment for empty tape in calculating the number of components on the reel.

Reel aMounts systems are used by leading electronics companies worldwide, including Jabil, Continental Automotive and Sony UK Technology Centre.

About Seratel

Seratel provides computer systems to aid electronics manufacturing. For 16 years, our systems have been used by leading OEMs and EMS providers. Seratel can be found on the web at www.seratel.ie and www.ReelaMounts.com or can be contacted by e-mail at info@seratel.ie.