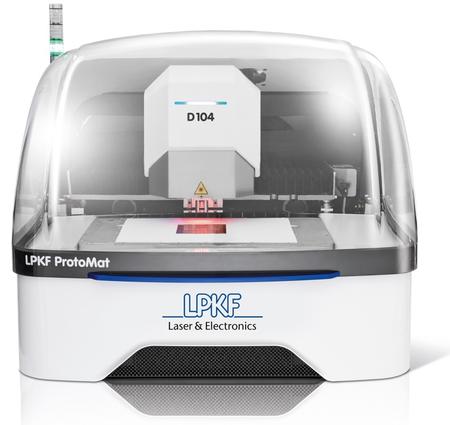

LPKF Laser & Electronics AG presents a spectacular new development: The LPKF ProtoMat D104 unites the best features of advanced LPKF ProtoMats with the high precision of the ProtoLaser systems. The highlight of this product innovation is a special UV laser.

Circuit board plotters in the LPKF ProtoMat range previously cut out circuit structures from completely coated base materials using negative milling. The ProtoMats mill insulation channels into the conductive layer, leaving the areas that will later be the conductive traces. Tool changing allows contours to be milled or vias to be drilled in circuit boards. LPKF ProtoLasers, on the other hand, are particularly useful when extremely fine structures are required.

The new LPKF ProtoMat D104 now extends the options of the ProtoMats to include machining of especially delicate materials. Thanks to the integrated UV laser-tool, the D104 enables structures down to the ultrafine conductor range to be produced. Depending on the material, structures with a pitch of 200 µm (100 µm minimum track width, 100 µm minimum space) can be applied by milling; with the laser tool, the achievable pitch is reduced to 80 µm (50 µm minimum track width, 30 µm minimum space). Even ceramics can be structured using the laser tool. The ProtoMat D104 is recommended for PCB prototyping, among other things, because of its extremely high precision, short machining times, high-speed milling/drilling at 100,000 RPM, 15 tool change options (automated) plus UV laser tool, non-contact tool depth setting and working depth limitation, a vision system with a measuring camera, and a maintenance-friendly housing.

The ProtoMat D104 was developed for use in highly demanding laboratory and development facilities. After internal introduction of the beta version at a distributors’ meeting, LPKF Laser & Electronics AG will present its innovation on November 12–15, 2013 at productronica in Munich (Hall B2, Booth 105). The LPKF ProtoMat D104 is expected to be ready for shipment in early 2014.

LPKF Laser & Electronics AG manufactures machines and laser systems used in electronics fabrication, medical technology, the automotive sector, and the production of solar cells. Around 20 percent of the workforce is engaged in research and development.

hitech.gif)