Engineered Material Systems, Inc., a leading global supplier of negative photoresist materials for MEMS and TSV passivation/sealing applications, is pleased to introduce the DF-3560 dry-film negative photoresist for use in micro-electro mechanical systems (MEMS), wafer-level packaging and CMOS applications (TSV sealing). This material formulation has been optimized for hot roll lamination and processing on MEMS and IC wafers.

DF-3560 is available in thickness formats from 5-100 µm, ±5 percent. The cured chemistry can withstand harsh environments including resistance to extreme moisture conditions and corrosive chemicals.

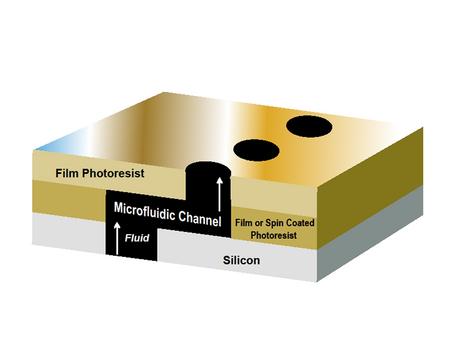

The DF-3560 film is tougher (less brittle) than most negative photoresists on the market with a glass transition temperature of 154°C (by DMA Tan Delta) and a moderate modulus of 3.25 GPa at 25°C. It is hydrophobic in nature, providing chemical and moisture resistance. DF-3560 is compatible with and can be used in contact with the EMS line of spin-coatable photoresists.

DF-3560 is the latest addition to Engineered Materials Systems’ full line of film and liquid negative photoresists formulated for making microfluidic channels on MEMS devices and integrated circuits.

For more information about the DF-3560 negative photoresist or to learn how Engineered Materials Systems can define, develop and create an engineered material solution that is right for your company, visit www.emsadhesives.com.

Engineered Materials Systems, Inc. (EMS) technology focus is on electronic materials for semiconductor, circuit assembly, photovoltaic, printer head, camera module, disk drive and photonics assembly product lines. The company creates continual improvements that will guide its customers into the future. For more information, visit www.emsadhesives.com.