NEO Tech, a leading provider of manufacturing technology and supply chain solutions for brand name OEMs in the industrial, medical and aerospace & defense markets, announces that it recently produced and published new and expanded guidelines for the manufacture of Low-Temperature Co-fired Ceramic (LTCC) and Aluminum Nitride (AlN) packaging solutions.

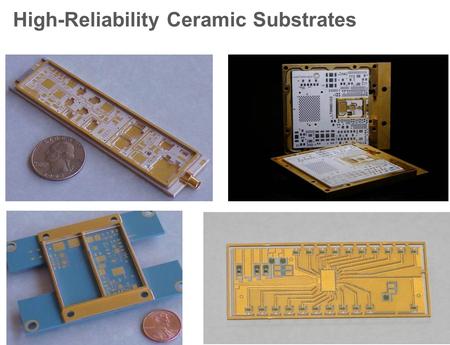

NEO Tech has emerged as North America’s leading manufacturer of high-reliability LTCC and high-temperature co-fired (HTCC) substrates and packages. These fabrication technologies provide unique solutions for high interconnect density, compact packages and high-frequency applications.

Key advantages include:

-

Embedded passive components

-

High density interconnect

-

Cost-competitive plated Silver systems

-

TCE closely matches that of Si, GaAs and SiC (and other associated compounds)

-

Brazed on components (connectors, seal ring, heat spreaders)

-

Hermetic packaging

-

Outstanding long-term reliability

The guidelines include comprehensive information that highlight capabilities, overview and standard design considerations, which include conductors, vias, cavities, special high-frequency design provisions, capacitors, inductors, post-fired conductors, soldering, material thermal properties, and electrical and mechanical properties of LTCC.

NEO Tech’s experience in ceramics processing has resulted in the development of the world’s most reliable multilayer ceramics technology available to the microelectronics industry. To learn more about how NEO Tech can assist with advanced packaging applications using ceramic substrates, or to download our design guides, visit www.neotech.com.

NEO Tech combines the strengths of three leading contract manufacturers: NATEL, EPIC, and OnCore. With over 40 years of heritage in electronics manufacturing, NEO Tech focuses on low-medium-volume/high-mix, high-complexity products primarily in the medical, aerospace & defense and industrial markets.

NEO Tech offers full product lifecycle engineering services, manufacturing and testing of microelectronics, cable & harness interconnect products, PCBA, full box build services and aftermarket repair and fulfillment services. The companies that form NEO Tech have been known for solving tough engineering problems that result in high-reliability, high-quality electronic solutions for customers.

Headquartered in Chatsworth, CA, NEO Tech has manufacturing and engineering locations in California, Colorado, Illinois, Massachusetts, Nevada, Ohio, Mexico, and China. NEO Tech holds and maintains industry specific certifications that include ISO9001, AS9100, ISO13485, ISO14001 and MIL-PRF-38534. To learn more, visit www.NEOTech.com.