The prerequisites for tomorrow's technologies

Scheugenpflug focuses on e-mobility and automomous driving and, with its high-quality dispensing solutions, is accompanying an imminent turn of events in the growth field of mobility.

KENNESAW, GEORGIA. Digitalization, e-mobility, automomous driving, industry 4.0 and energy system transformation: Many of today's megatrends would be unachievable without safe, reliable electronics. These electronics are becoming smaller, more complex and more powerful, and at the same time the damands on their longevity and reliability are increasing. Modern adhesives, sealants and encapsulatns are used to protect these components from harmful influences in the long term. The systems for the application of these materials to the components were supplied by Scheugenpflug AG, headquartered in Neustadt/Donau. The product and technology range of the East Bavarian company, which has branches in the USA, China, Mexico and Romania and employs a total of just under 700 people, is diverse: In addition to dispensing systems and systems for material preparation and feeding, it also includes customer-specific inline and automation solutions.

With this portfolio, the company also sees itself well equipped regarding the growing field of mobility. Because e-mobility poses one of the greatest challenges in the history of the automotive industry. "However, we must not reduce our mobility to drivetrain alone", says Christian Geier, CEO of Scheugenpflug Inc.

Irrespective of whether we are talking about hybrids or pure e-cars, another change has long since taken place: Our vehicles have become "rolling computers" with a growing number of electronic components. Systems such as ABS, light and rain sensors as well as airbags have become standard features. Driver assistance systems such as fatigue detection or emergency brake assist are also gaining ground in all model segments. And the more stages the vehicle passes through on its way to fully autonomous driving, the more systems will be added. "The smooth functioning of computers, sensors, control units or cameras depends on, among other things, optimally applied sealants and adhesves, potting compaounds and thermally conductive pastes", explains Geier. "They protect the parts and components from harmful influiences such as gigh temperatures, dirt, moisture or strong vibrations and prevent costly and safety-relevant part failures and defects." And all this is essential for the safety of road users.

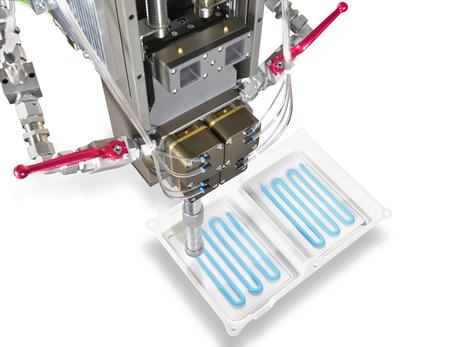

With the further development of electronics, the demands on dispensing technology are also changing. The bonding, sealing and potting tasks are becoming more and more demanding. At the same time, more and more casting resins with very complex formulations or high filler content are being used. Processing these media con be very challenging. An example is the potting of high-voltage batteries used in electric vehicles. In order to prevent damage to the battery and vehicle due to excessive temperatures, large quantities of thermally conductive paste are used. Several l iters of these media are dispensed per vehicle between the battery modules and the enclosing housing. Scheugenpflug has developed a new dispensing solution especially for this purpose, consisting of the Dos HP hgih-performance dispensing unit and the PailFeed200 Abrasive material feeding unit. here it is possible to connect two feeding systems parallel with the dispensing unit and thus realize redundant system operation without downtimes. Even with highly abrasive thermally conductive materials, the system allows dispensing speeds of up to 80 ml/s.

Whether it is head-up displays, digital mirrors or touchscreens - the number of displays installed in cars is constantly increasing. Especially on the way to the autonomous vehicle, these are becoming increasingly important as human-machine interfaces (HMI). The adhesive, dispensing and potting solutions of Scheugenpflug are also used here. "In the first step, vehicle displays are all about good legibility, high robustness and optimum touch functions", explains the Scheugenpflug CEO. "However, safety-relevant aspects such as the head impact test are also becoming increasingly important. this is why these displays are optically bonded, i.e. bonded with liquid, highly transparrent adhesives. The highes quality is required here because the end users interact directly with the displays."

For more information contact Scheugenpflug Inc. at sales.us@scheugenpflug-usa.com, call +1 770 218 0835, or visit our website: www.scheugenpflug-usa.com.

hitech.gif)