Pneumatic Cylinder

Many industrial applications require linear motion during their operating sequence. One of the simplest and most cost-effective ways to accomplish this is with a pneumatic actuator, often referred to as an air cylinder. An actuator is a device that translates a source of static power into useful output motion. It can also be used to apply force. Actuators are typically mechanical devices that take energy and convert it into some kind of motion. That motion can be in any form, such as blocking, clamping, or ejecting.

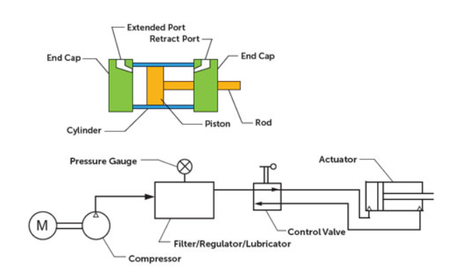

Pneumatic actuators are mechanical devices that use compressed air acting on a piston inside a cylinder to move a load along a linear path. Unlike their hydraulic alternatives, the operating fluid in a pneumatic actuator is simply air, so leakage doesn’t drip and contaminate surrounding areas.

There are many styles of pneumatic actuators including diaphragm cylinders, rodless cylinders, telescoping cylinders and through-rod cylinders.

The most popular style of pneumatic actuator consists of a piston and rod moving inside a closed cylinder. This actuator style can be sub-divided into two types based on the operating principle: single acting and double acting.

Single-acting cylinders use one air port to allow compressed air to enter the cylinder to move the piston to the desired position, as well as an internal spring to return the piston to the “home” position when the air pressure is removed.

Double-acting cylinders have an air port at each end and move the piston forward and back by alternating the port that receives the high-pressure air.

In a typical application, the actuator body is connected to a support frame and the end of the rod is connected to a machine element that is to be moved. An on-off control valve is used to direct compressed air into the Extended port while opening the Retract port to the atmosphere. The difference in pressure on the two sides of the piston results in a force equal to the pressure differential multiplied by the surface area of the piston.

If the load connected to the rod is less than the resultant force, the piston and rod will extend and move the machine element. Reversing the valving and the compressed air flow will cause the assembly to retract back to the “home” position.

Pneumatic actuators are at the working end of a fluid power system. Upstream of these units, which produce the visible work of moving a load, are compressors, filters, pressure regulators, lubricators, on-off control valves and flow controls. Connecting all of these components is a network of piping or tubing (either rigid or flexible), and fittings.

Pressure and flow requirements of the actuators in a system must be taken into account when selecting these upstream system components to ensure desired performance. Undersized upstream components can cause a pneumatic actuator to perform poorly, or even make it unable to move its load at all.

Pneumatic Cylinder is available through Quick Time Engineering Inc.

Quick Time Engineering Inc is an international company with offices and distribution networks in the USA, Hong Kong, Europe and Malaysia.

In its 20 years of operation since 1998, Quick Time Engineering Inc had emerged from a local engineering company with a single staff that provided solutions in factory automation to become nowadays a company that serves the Oil & Gas industries, EPC contractors, System Integrators and other industrial automation and process control companies worldwide. Customers from over 50 countries worldwide trust us with their need for process control instruments and industrial automation products.

For more information about Quick Time Engineering Inc, visit www.quicktimeonline.com or email enquiry@quicktimeonline.com

.gif)