Needle Valve

Needle Valves, sometimes referred also as Plunger Valves, are regulating valves and enable engineers to finely control and regulate fluid flow and pressure. Needle valves are similar to the globe valve in design with the biggest difference is the sharp needle-shaped disk. The needle valve has a small port and a threaded needle-shaped plunger. This arrangement permits a very gradual increase or decrease in the size of the opening allowing precise regulation of flow, although it is generally only capable of relatively low flow rates.

Needle valves can operate manually or automatically. Automated needle valves are connected to a hydraulic motor or an air actuator that automatically opens and closes the valve. The motor or actuator will adjust the plunger’s position according to timers or external performance data gathered when monitoring the machinery. Both manually operated and automated needle valves provide precise control of the flow rate.

One design feature of most needle valves dictates that a considerable number of turns are required to make even a small amount of space open up. This enables gradual, accurate and precise control over the amount of liquid/gas that can pass through the valve. Additionally, this can prevent damage to gauges which could be affected by sudden bursts of liquid/gas and allows for better control and regulation in general.

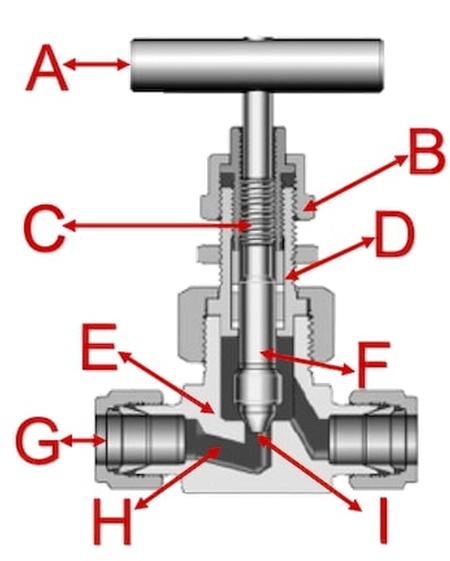

Needle valves open and close an orifice like valve opening with a tapered needle-shaped disc that raises and lowers with the spin of a hand-wheel or with the help of any automatic control mechanism. The figure shows a needle valve cross-sectional view, design, and components. The hand-wheel (A) is connected to the plunger, also called stem (F). When one turns the handle, the plunger moves up or down based on the threads (C). The locking nut (B) prevents the plunger from fully unscrewing. As the plunger moves down, the tapered pointed end (I) comes into contact with the valve seat to fully seal the valve opening (H). Often, the valve seat is also tapered. The valve’s needle-like plunger fits into the seat. Because of this unique design, a needle valve can precisely and accurately control how much fluid passes through the valve. When the hand-wheel is turned in one direction, the plunger is lifted to open the valve and allow fluid to pass through. When the hand-wheel is turned in the other direction, the plunger moves closer to the seat to decrease the flow rate or close the valve. There are various options and sizes available to connect it to a pipe or hose through the port connection (G) on the inlet and outlet. The bonnet (D) is connected to the valve housing (E), which can be made out of different materials like brass or stainless steel.

Needle Valve is available through Quick Time Engineering Inc.

Pipe Tee

A pipe tee is a type of piping fitting which is T-shaped having two outlets, at 90 degrees to the connection to the mainline. It is a short piece of pipe with a lateral outlet. A pipe tee is used to connect pipelines with a pipe at a right angle with the line. Pipe tees are widely used as pipe fittings. They are made of various materials and available in various sizes and finishes.

Pipe Tee is available through Quick Time Engineering Inc.

Quick Time Engineering Inc is an international company with offices and distribution networks in the USA, Hong Kong, Europe and Malaysia.

In its 20 years of operation since 1998, Quick Time Engineering Inc had emerged from a local engineering company with a single staff that provided solutions in factory automation to become nowadays a company that serves the Oil & Gas industries, EPC contractors, System Integrators and other industrial automation and process control companies worldwide. Customers from over 50 countries worldwide trust us with their need for process control instruments and industrial automation products.

For more information about Quick Time Engineering Inc, visit www.quicktimeonline.com or email enquiry@quicktimeonline.com