Global electronic demand continues to grow, but so too does the component shortage. The lack of parts to meet demand has impacted electronics supply chains, and this trend looks set to remain in 2023. With parts becoming expensive and more difficult to obtain, ensuring that the available supply is used carefully has never been more important.

Manufacturers are turning to Altus Group, a leading distributor of capital equipment for electronics assembly in the UK and Ireland, to help them improve their assembly quality.

Anthony Oh, Altus Technical Applications Manager explains: ‘’Implementing BGA inspection into production has never been more important. As BGA components become more valuable than ever, we have seen unprecedented requests from companies looking to improve the quality of the SMT assembly process.

“X-ray is perhaps the gold standard for void calculation if affordable or available on-site, but Optilia’s BGA Inspection unit offers customers a great alternative to inspect for BGA assembly quality at a fraction of the price. With its high capability traceability options and innovative software, it is an excellent entry point for a facility looking to increase its capacity to inspect and review BGAs.

“Our customers also really appreciate the option of picking and choosing the right configuration for their facility. Some have bought XL configurations with all the trimmings, with others opting for the standard inspection unit. Some have even requested bespoke mounts with handheld units embedded. There is a solution for all price points, which is why we have seen such demand for Optilia.’’

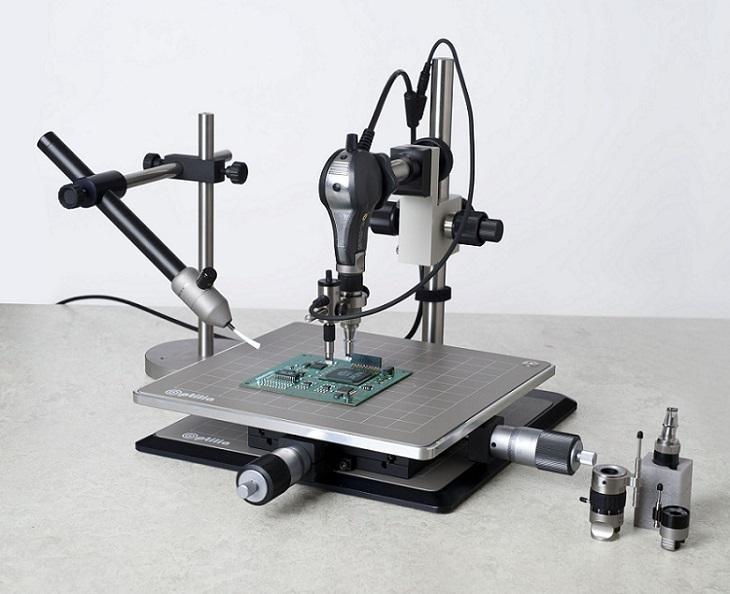

Optilia’s inspection device, in its simplest form, is a handheld optical microscope. It can use a variety of lenses for BGA inspection, depending on the pitch and the magnification required, to provide an image of the internal rows of solder balls.

For more precise inspection needs, there is a choice of fixed mounts, extra lighting, additional lenses, movable X-Y tables and Optipix software. These additions allow manufacturers to reduce the skill level required to achieve a good image of the solder balls.

Anthony concluded: “We understand that investment in new equipment is a big decision to make. It has to work with existing assembly processes and meet inspection goals. For this reason, we can run sample validation with a customer’s product using the Optilia equipment to ensure it is the right fit.”

To find out more about Optilia hand-held inspection equipment or the other options available from Altus, including X-ray and AOI platforms, visit www.altusgroup.co.uk.

Altus Group was formed in 2001 to support the UK and Irish market for Surface Mount Technology, capital equipment for every process, peripheral equipment, spares and consumables and most importantly excellent service support.

The Altus Group product line has evolved over the years with carefully selected suppliers who offer ‘best in class’ products at cost effective prices, from world leading brands.

The Altus Team has a network of highly skilled technical sales specialists, applications and service engineers, providing local support across the UK and Ireland.

In 2005 sister company Danutek was formed with offices in Hungary and Romania to service the needs of local customers and multi-national companies with manufacturing facilities in the Central and Eastern European marketplace.

www.altusgroup.co.uk