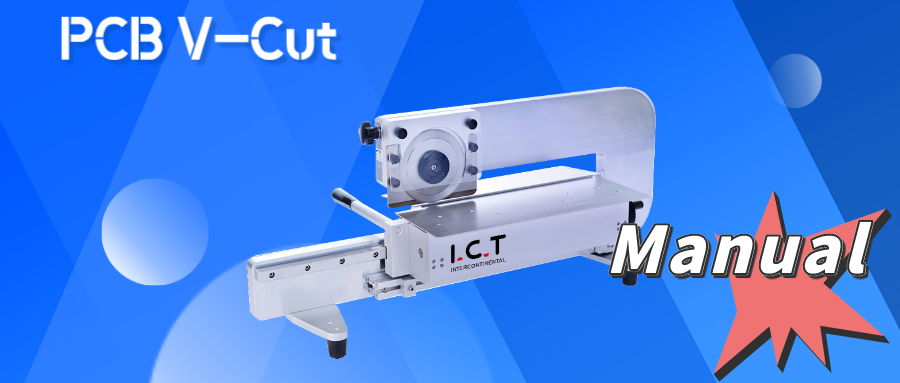

Introducing the I.C.T-MV350 Manual V-Groove PCB V- Cutting Machine

When it comes to PCB assembly, precision is paramount, and having the right equipment can be a game-changer. Allow us to introduce the I.C.T-MV350 PCB V-Cutting Machine, a robust solution that will take your PCB manufacturing process to the next level. In this comprehensive guide, we'll delve into the exceptional features and capabilities that set the I.C.T-MV350 apart from the competition.

The PCB Cutting Machine: Where Precision Meets Stability

The I.C.T-MV350 PCB Cutter is known for its rock-solid stability, ensuring that your PCBs stay securely in place during the separation process. This stability minimizes the risk of component damage, a critical concern in the world of PCB assembly.

Fine-Tune Your PCB V-Cutting Machine Process

A standout feature of the I.C.T-MV350 PCB Cutting Machine is its manually adjustable blade speed. This flexibility empowers operators to fine-tune the cutting process, accommodating various PCB types and ensuring a perfect cut every time.

PCB V-Cutting Machine: Unmatched Precision at Varying Depths

The I.C.T-MV350 offers precise adjustment for the distance between the circular blade and the straight blade. This precision is crucial, especially when dealing with V-slots of varying depths. The machine seamlessly adapts to the unique requirements of each PCB.

Achieve Versatile Component Positioning with PCB Cutting Machine

Another highlight of the I.C.T-MV350 is its compatibility with situations where components intersect V-slots. This adaptability ensures that no matter how intricate your PCB design, the I.C.T-MV350 delivers clean and precise cuts without compromise.

Minimize Solder Cracks with PCB Cutting Machine

The I.C.T-MV350 excels at minimizing internal pressure during the separation process, reducing the risk of solder cracks. This feature guarantees the long-term reliability and quality of your PCBs.

Efficiency and Precision Combined: PCB Cutting Machine

Efficiency is at the core of the I.C.T-MV350 Manual V-Groove PCB Cutting Machine. Its precision, stability, and adaptability contribute to a smoother PCB assembly process, ultimately improving the quality of your end products.

The manual blade speed adjustment allows operators to control the cutting process precisely, ensuring that every PCB is separated with accuracy and care. Additionally, the machine’s adaptability to various PCB depths and component positioning scenarios makes it a versatile addition to any assembly line.

The I.C.T-MV350 is designed to enhance efficiency without compromising the quality of the final product. It's a solution that prioritizes precision and reliability while streamlining the PCB separation process.

Conclusion

Unlock the Potential of Precision and Efficiency with I.C.T-MV350 PCB Cutting MachineUnlock the potential of precision and efficiency with the I.C.T-MV350 Manual V-Groove PCB Cutting Machine. Elevate your PCB manufacturing process by investing in this powerful tool.

Ready to experience the benefits of the I.C.T-MV350 for yourself? Contact Us to learn more about how this exceptional machine can revolutionize your PCB assembly. Your journey to unparalleled precision starts here.

»

»