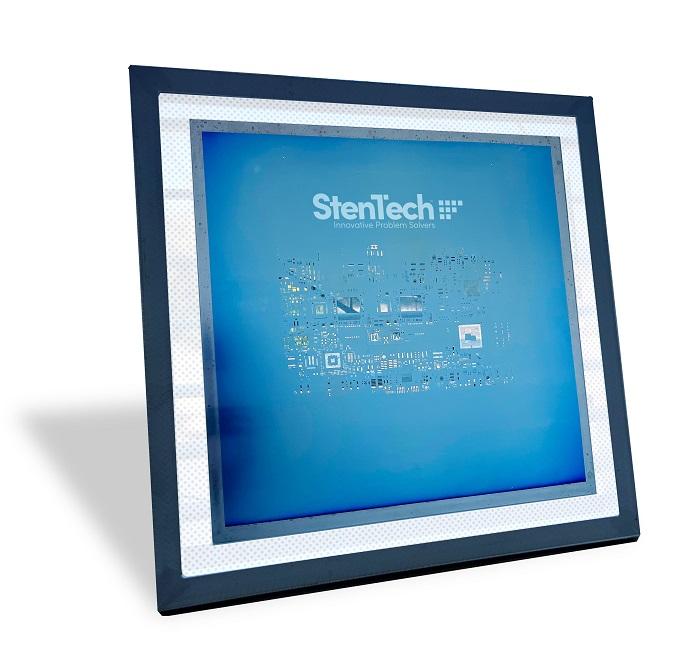

StenTech® Inc. is proud to announce the U.S. launch of its StenTech BluPrint™ PVD Stencils, a groundbreaking Physical Vapor Deposition (PVD) technology that optimizes SMT production by enhancing precision, durability, and productivity. With 98% transfer efficiency, StenTech BluPrint™ maintains consistent performance across high-volume runs of up to 50,000 prints, reducing cleaning cycles by up to 300%. This advanced coating supports complex PCB designs with lower area ratios, resulting in fewer disruptions, minimized defects, and higher throughput.

“We are proud to introduce StenTech BluPrint™ to the U.S. market, offering manufacturers a solution that elevates reliability and cost-efficiency,” said Brent Nolan, President & COO of StenTech. “Our unique vapor deposition coating helps push design boundaries while ensuring lasting stencil performance, making it ideal for today’s high-demand SMT environments.”

StenTech BluPrint™ combines anti-stiction properties, high thermal stability, and customizable coating characteristics, ensuring precision solder paste deposition and a smooth, reliable finish for every application. With StenTech BluPrint™, manufacturers can achieve greater productivity, fewer disruptions, and more confidence in every print. This technology elevates SMT processes to a new level of efficiency and reliability.

For more information about StenTech and the StenTech BluPrint™ PVD Surface Treatment, please visit www.stentech.com/BluPrint.

StenTech sets the industry standard for precision, reliability, and speed in SMT printing solutions. We deliver unmatched quality and support to ensure your success. By mitigating risks and minimizing downtime with our rapid turnaround precision products, we help your business maintain smooth and efficient production lines, ensuring profitability and success. ©2024

StenTech BluPrint™ is a trademark of StenTech Inc.

.gif)